Two-gear transmission

A transmission and brake technology, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of not being able to make full use of two-speed transmissions, shifting failures, and high requirements for control systems, and achieve simple and reliable shifting methods , The shifting process is smooth and simple, and the effect of low control system requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

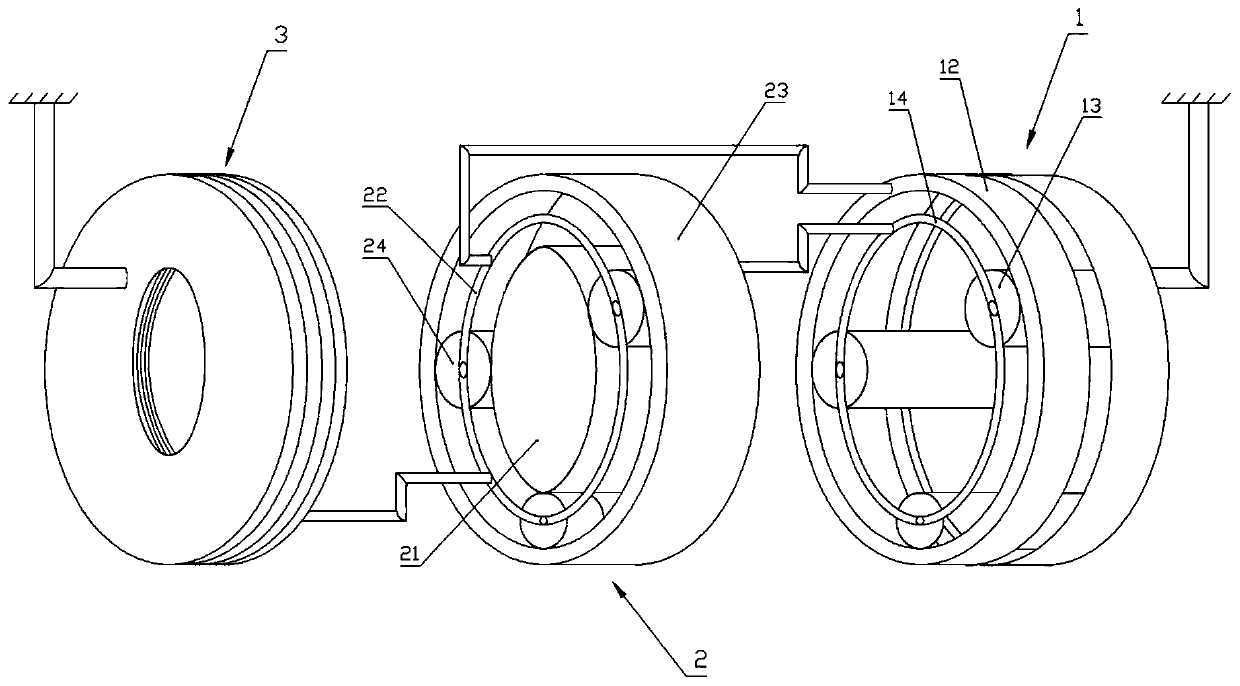

[0017] like figure 1 As shown, the two-speed transmission provided by this embodiment includes a constant mesh tooth two-way overrunning clutch 1 , a shunt assembly 2 and a brake 3 arranged in the casing.

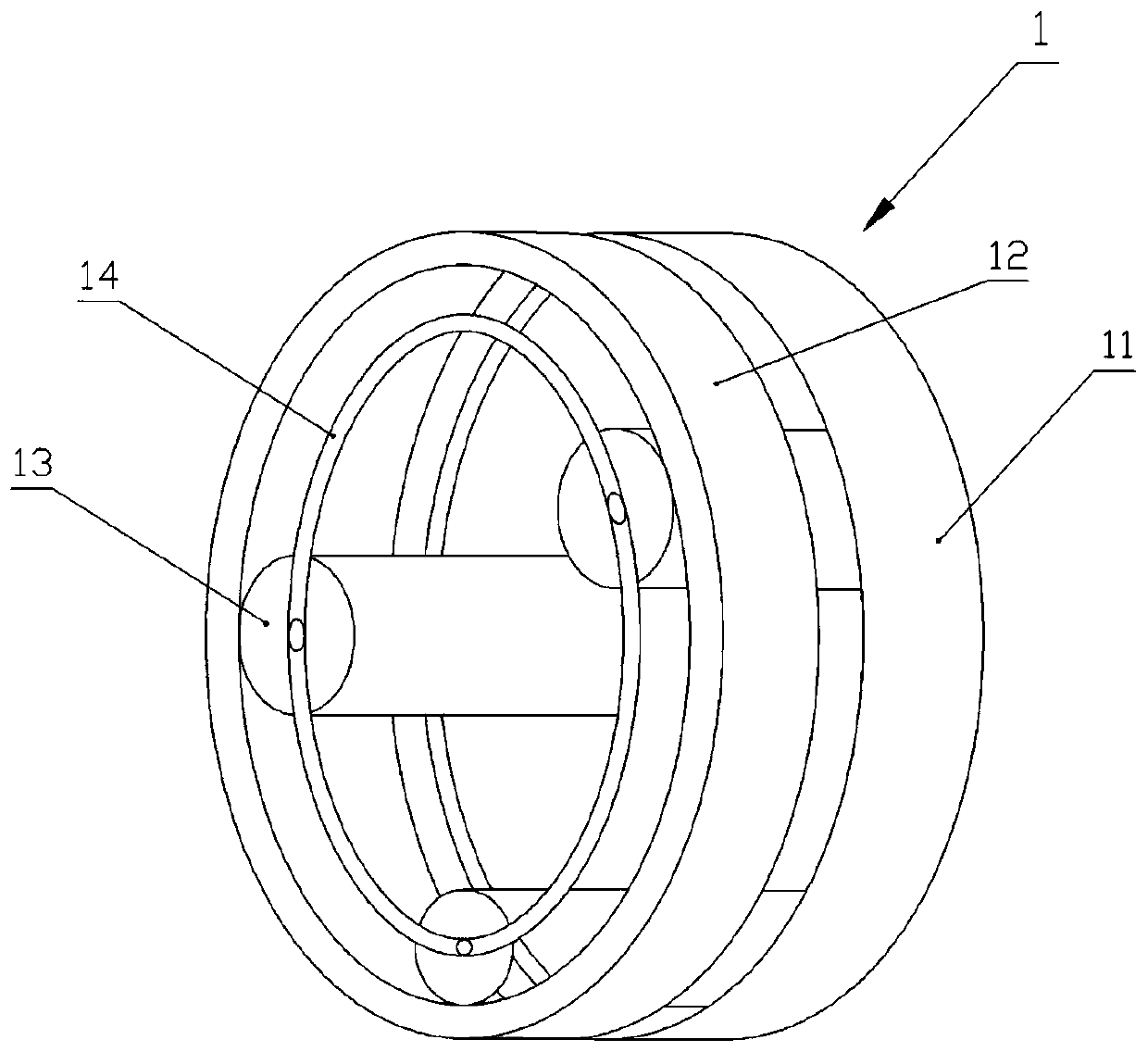

[0018] like figure 2 As shown, the constant mesh tooth two-way overrunning clutch 1 includes fixed teeth 11 , input teeth 12 , transmission assembly 13 and output member 14 . The fixed teeth 11 and the input teeth 12 are ring gears with the same specifications, and the fixed teeth are fixed in the casing. The transmission assembly 13 is three long planetary gears evenly distributed in the ring gear, and one end of the long planetary gears meshes with the fixed ring gear. , the other end meshes with the input ring gear; the output member 14 is a planetary carrier fixedly connected to each long planetary gear shaft. One end of the same long planetary gear meshes with the fixed ring gear, and the other end meshes with the input ring gear to ensure that the ratio of the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com