A non-powered underwater hose automatic storage device

A storage device and power water technology, applied in underwater operation equipment, transportation and packaging, cargo handling equipment, etc., can solve the problems of complicated operating system, increased cost, and increased operating system, achieving compact structure, convenient operation, Precisely controllable frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

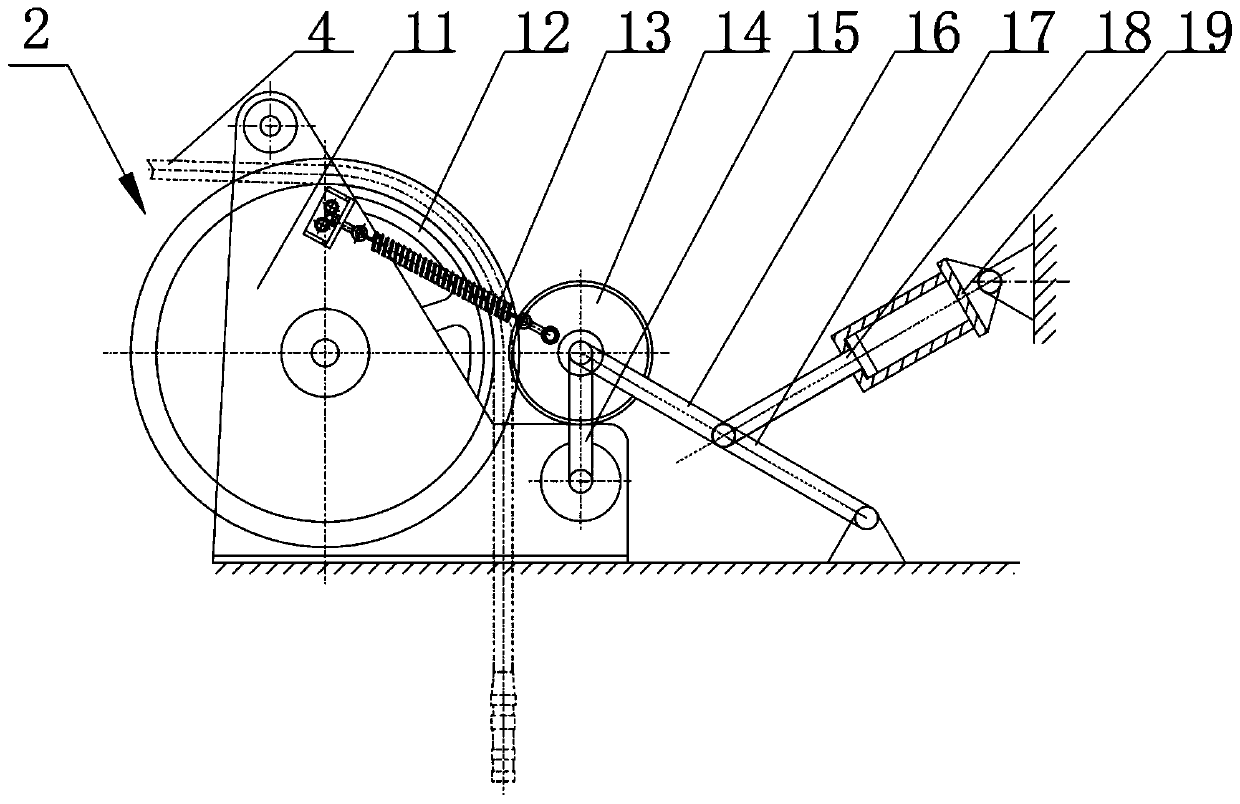

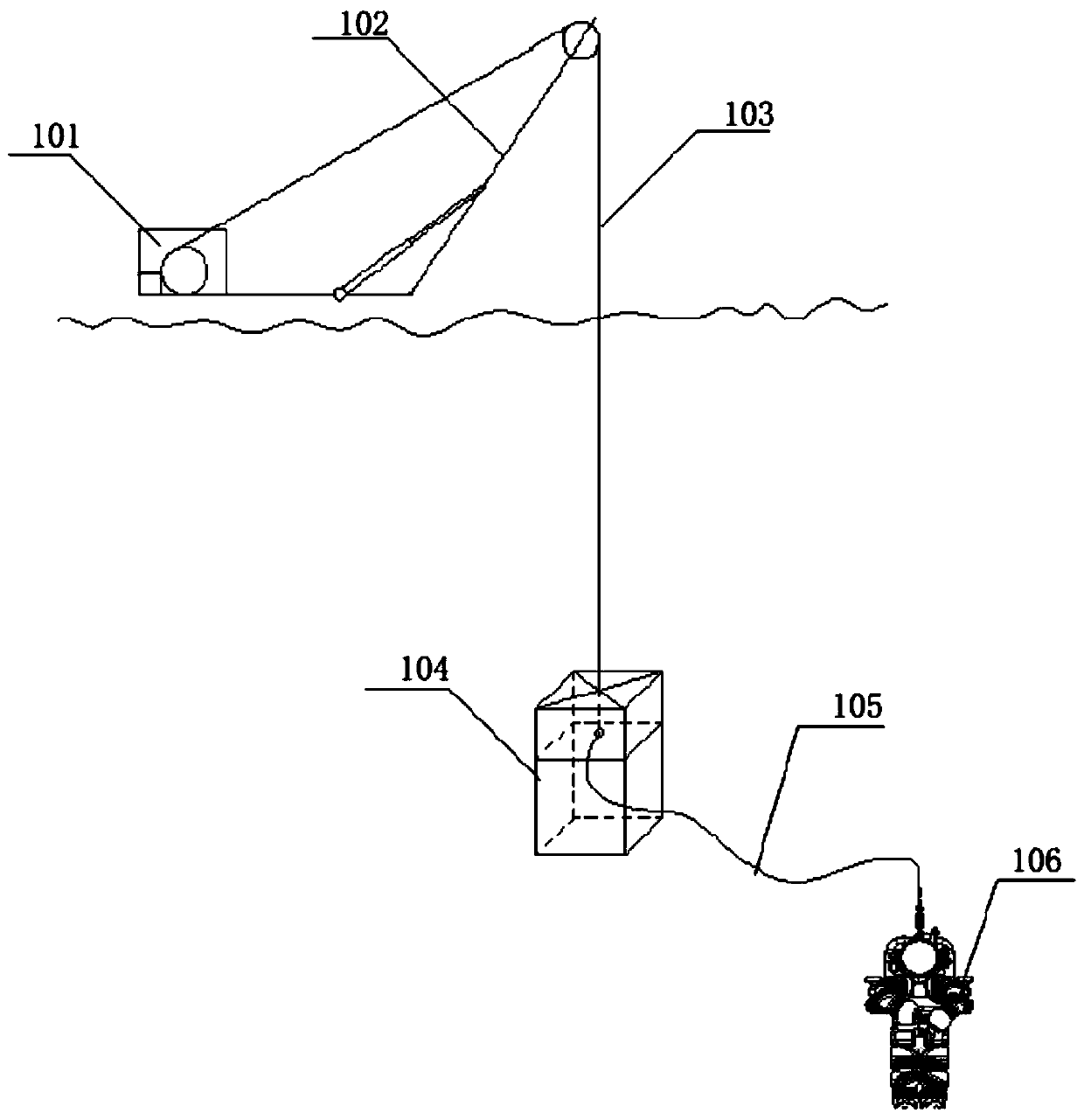

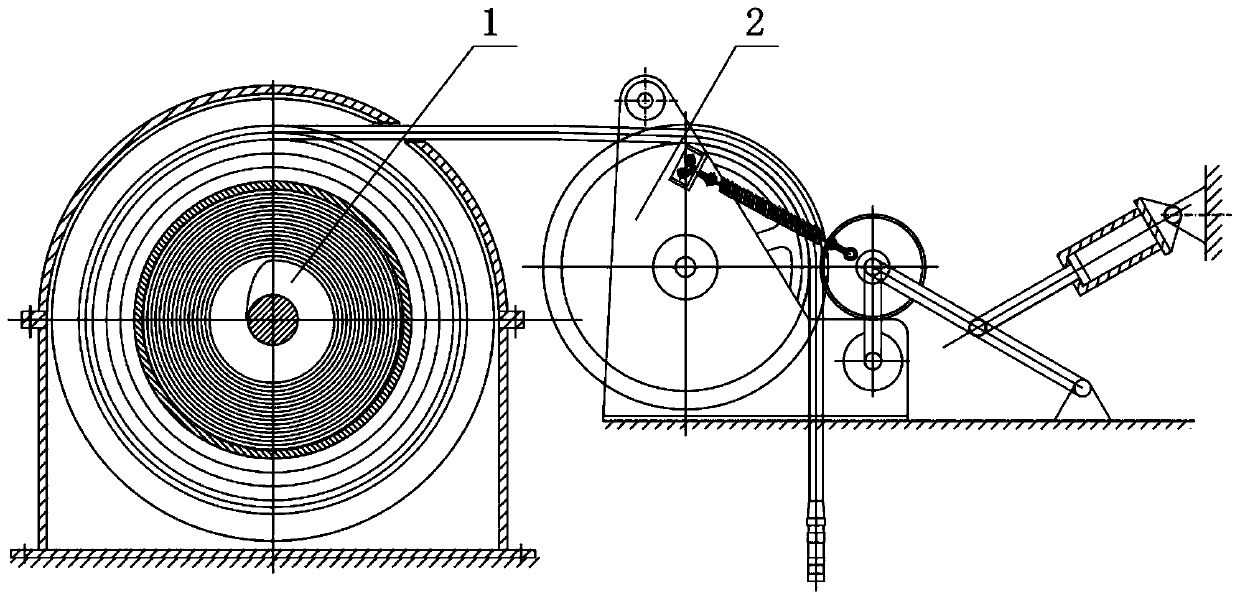

[0032] like figure 2 , image 3 and Figure 4 As shown, the unpowered underwater hose automatic storage device of this embodiment includes a cable storage winch 1, a hose 4 is wound on the cable storage winch 1, and the hose 4 is wound into the cable guide mechanism 2; Concrete structure is: comprise the support 11 that is fixed on the bottom frame, guide wheel 12 is supported and installed in the support 11, and swing lever 15 is also hinged on the side of shown support 11, and the head of swing lever 15 is fixed with pinch wheel 14, presses. The pinch wheel 14 is positioned at the side of the guide wheel 12, and the extended end of the flexible pipe 4 is clamped between the pinch wheel 14 and the guide wheel 12; The head is hinged with a crank 17, and the base frame is also fixed with a hinge seat. The crank 17 is installed on the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com