Disposable steel cylinder gas filling production line and production method thereof

A cylinder gas, disposable technology, applied in the field of cylinder canning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] refer to Figure 1 to Figure 7 An embodiment of the present invention will be further described.

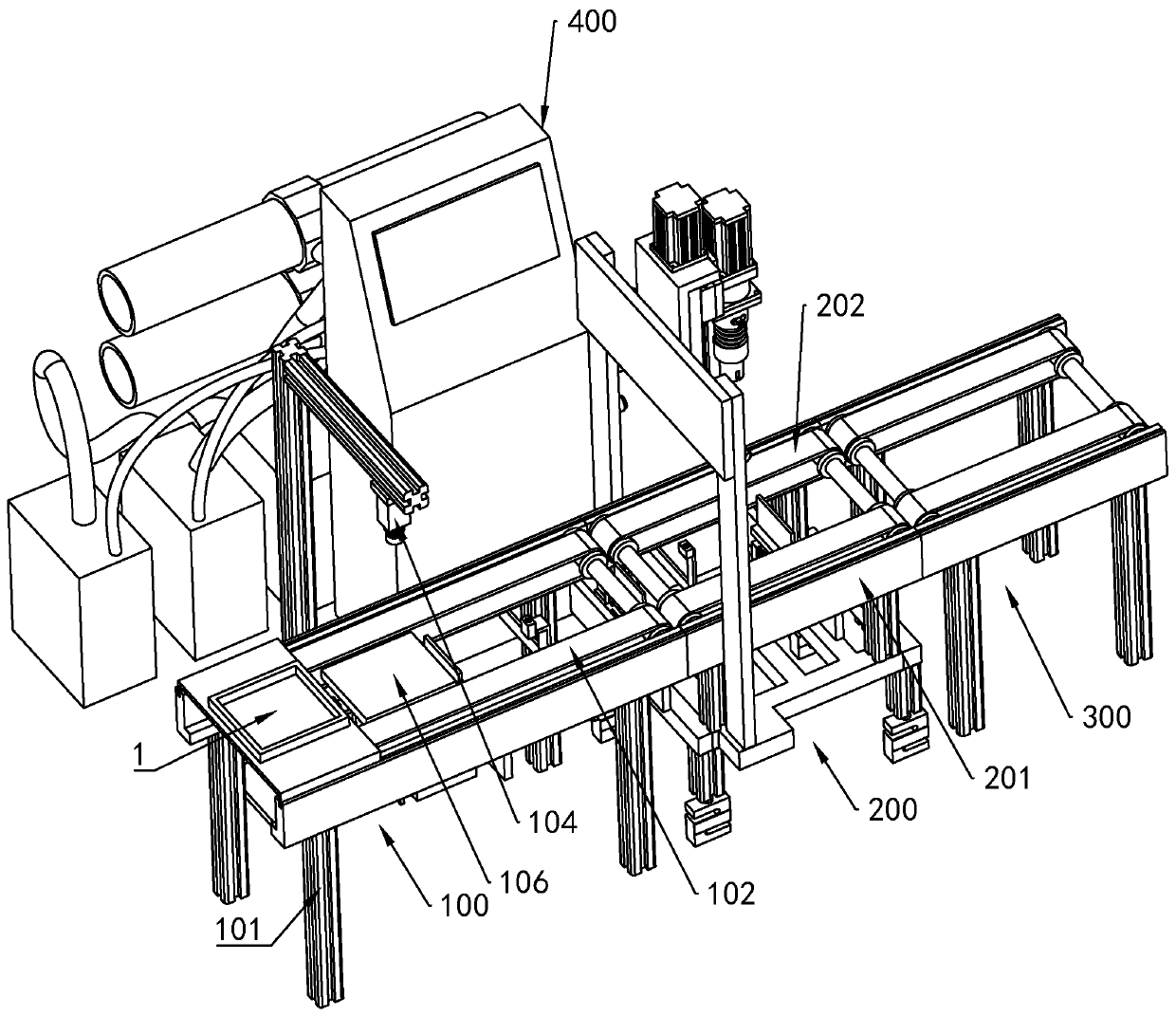

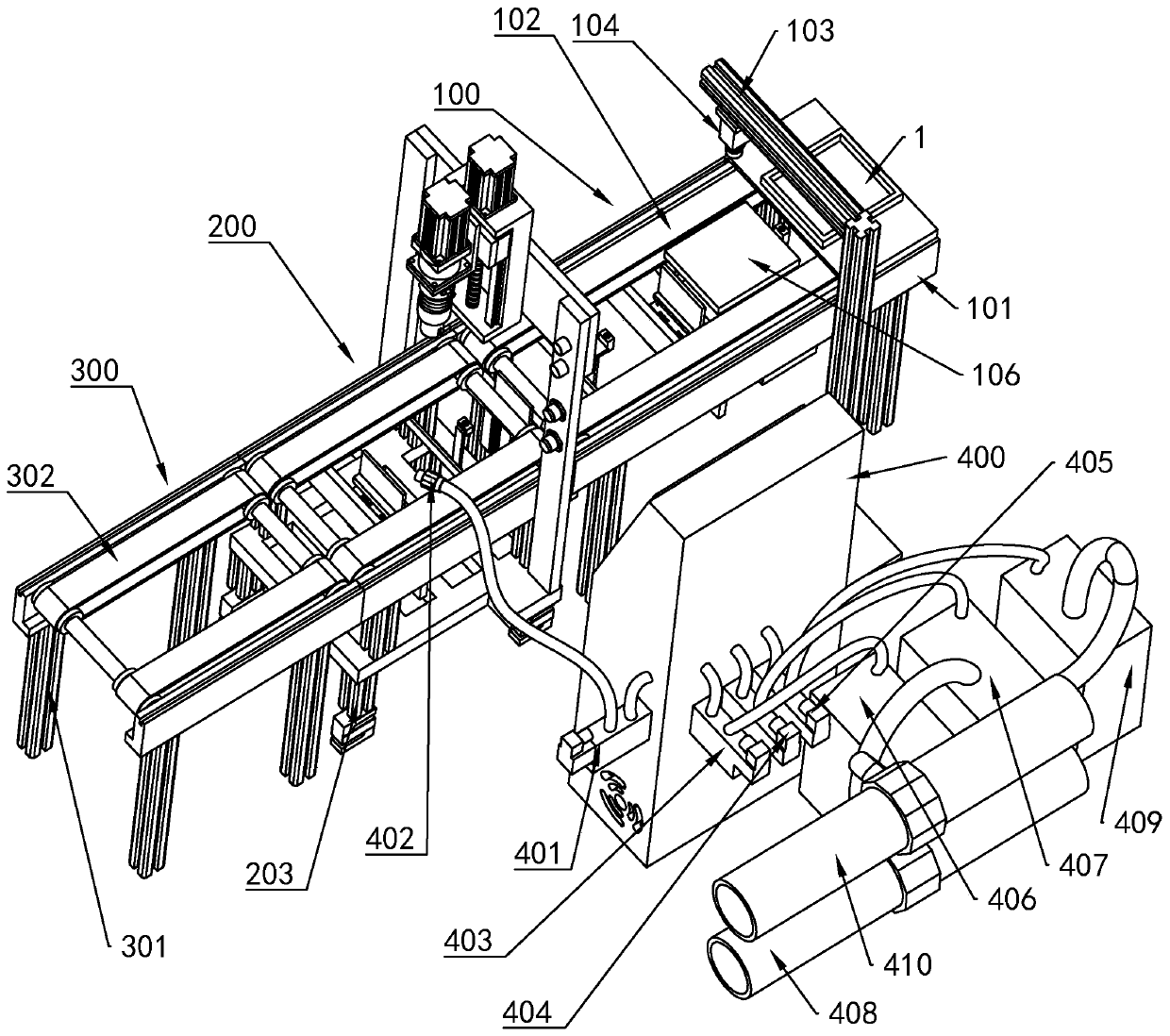

[0049] A disposable steel cylinder gas filling production line is characterized in that: the production line includes a steel cylinder type detection station 100, a steel cylinder filling station 200, a steel cylinder conveying station 300 and a control cabinet 400 connected in sequence; the steel cylinder The model detection station 100 is used to detect the model of the steel cylinder to be filled, the steel cylinder filling station 200 cans the steel cylinder, and the steel cylinder transport station 300 is used to transport the canned steel cylinder; The control cabinet 400 described above is provided with a controller and a control circuit to control each station.

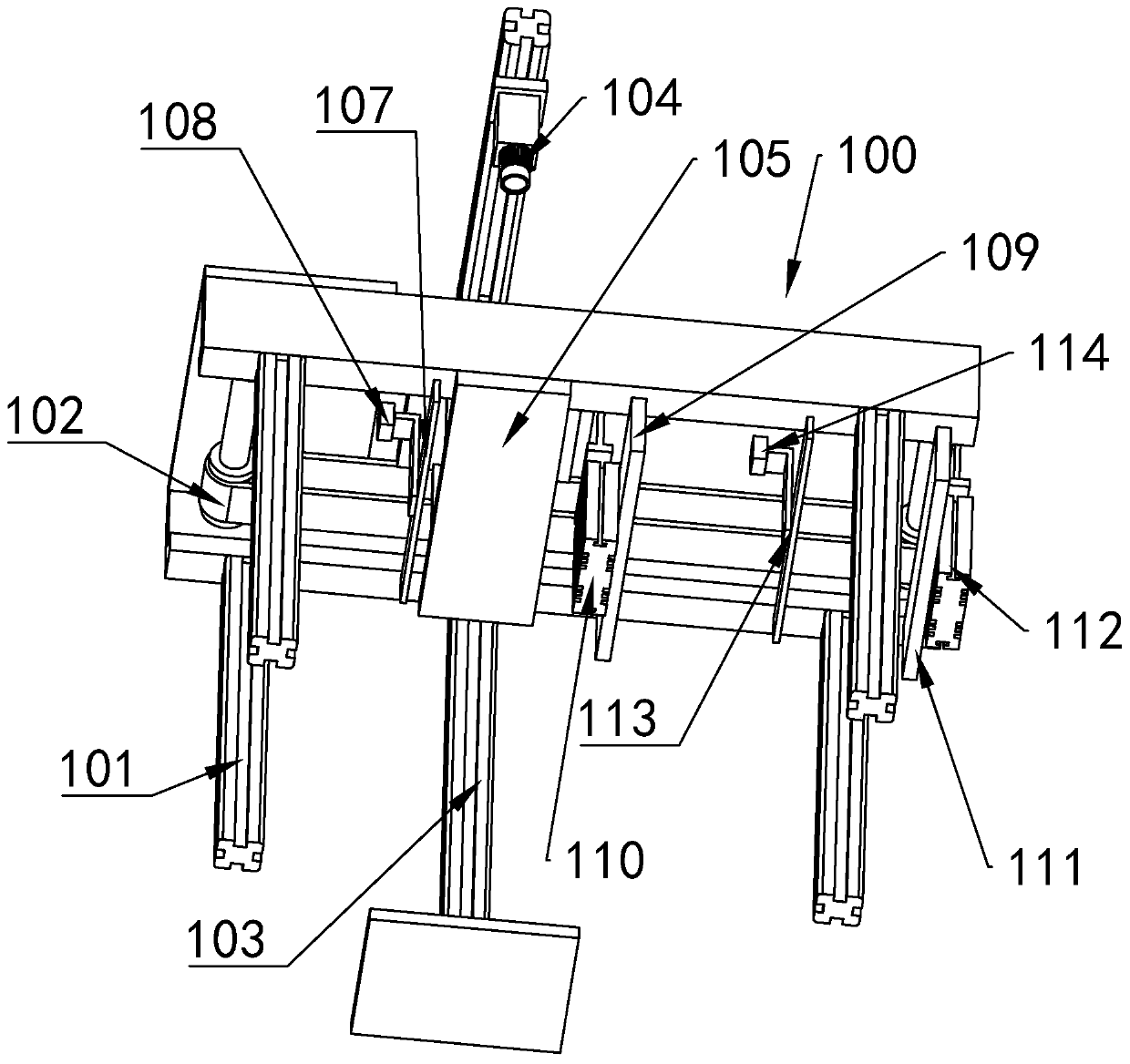

[0050] The steel cylinder type detection station 100 is composed of a first support frame 101, a first conveyor belt 102 arranged on the first support frame 101 and a tray 1 placed on the first conveyor b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap