Anti-slip water meter and working method thereof

An anti-idling, water meter technology, applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve problems such as unsanitary, affecting the health of users, and unstable water supply pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0021] Working method of the present invention:

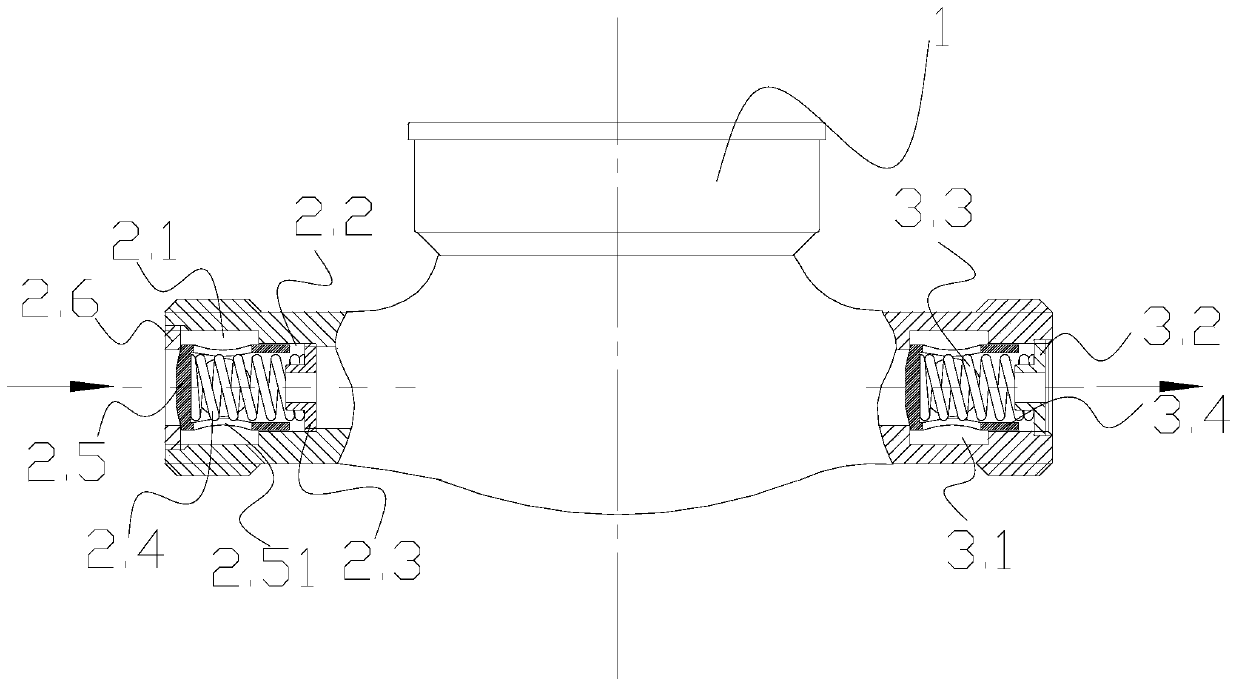

[0022] When the water flow passes, the water pressure makes the first valve core 2.5 compress the first spring 2.4, and the water flows in from the gap between the sealing plate 2.6 and the first valve core 2.5, and passes through the side wall outlet 2.51 of the first valve core 2.5 and the first spring The flow hole of the seat 2.3 flows into the metering mechanism; then the water pressure makes the second valve core 3.4 compress the second spring 3.3, and the water flows through the side wall of the second valve core 3.3 from the gap between the second valve core 3.3 and the third installation chamber 3.1 The hole flows out of the hole with the second spring seat 3.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com