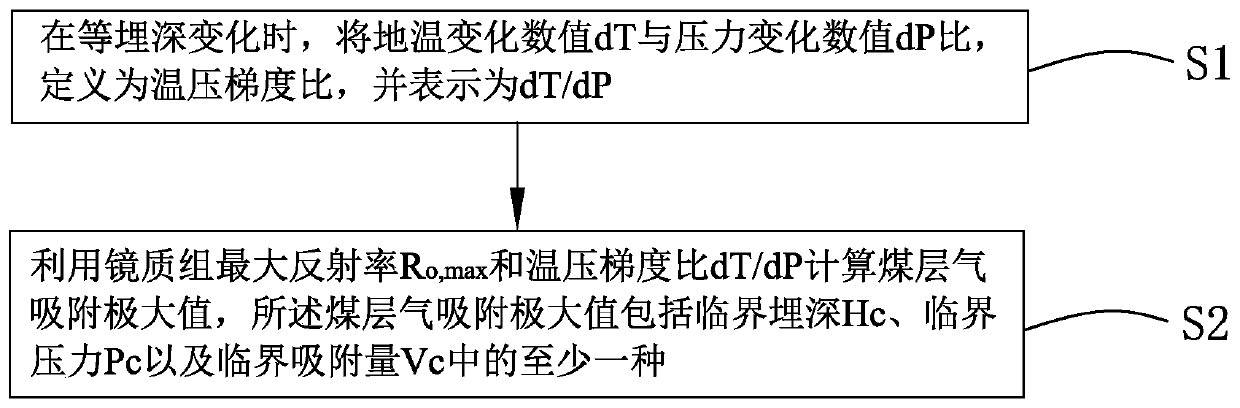

Method for calculating maximum coal-bed gas adsorption value based on coal rank and temperature-pressure gradient ratio

A technology of coalbed methane and maximum value, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as not easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0044] During exploration and development, the maximum reflectance R0,max of coal vitrinite is 0.84, the geothermal gradient is 2.98℃ / hm, and the pressure gradient is 1.20MPa / hm.

[0045] The method comprises the steps of:

[0046] Calculate the temperature-pressure gradient ratio according to the geothermal gradient and pressure gradient of the coal sample

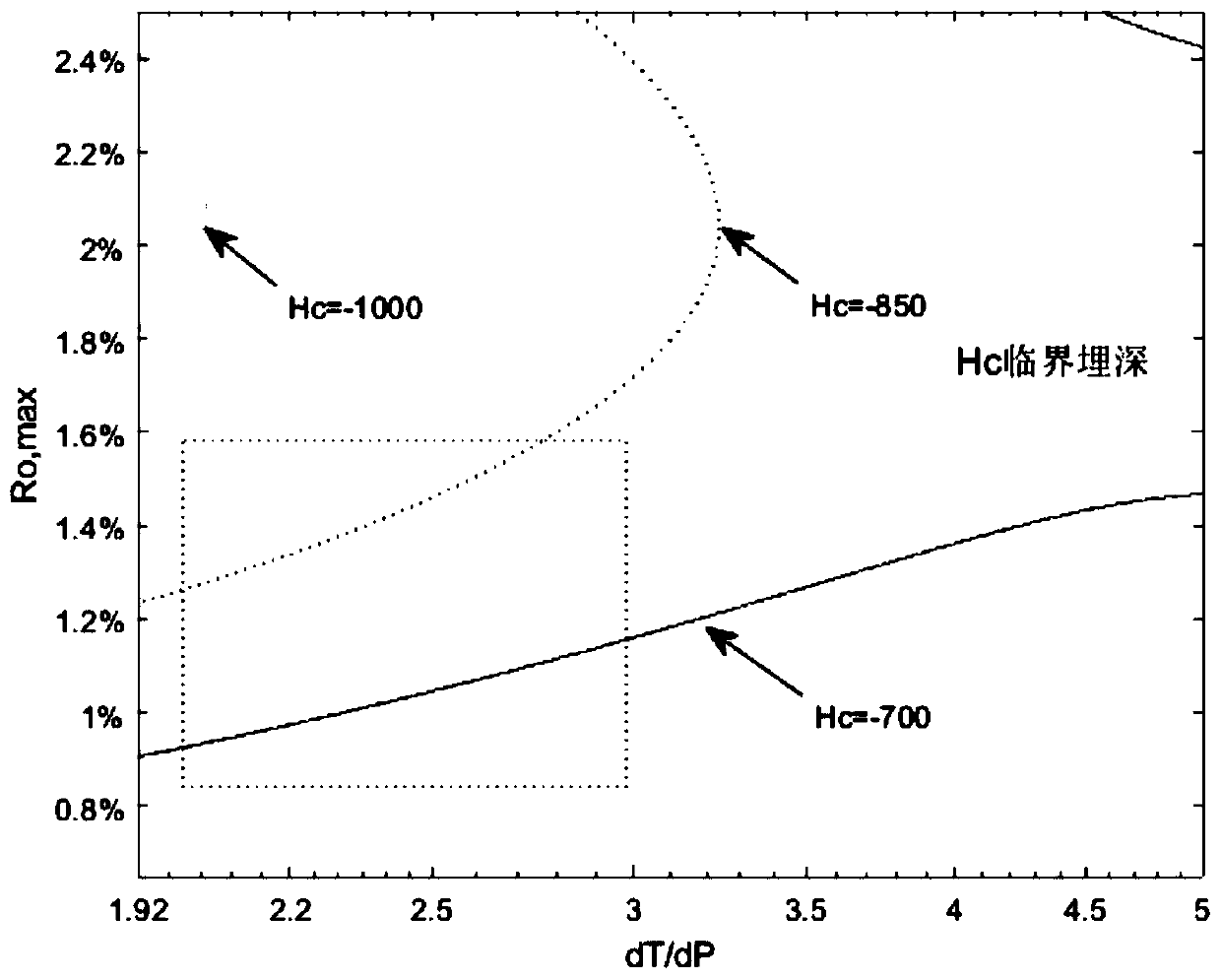

[0047] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical buried depth Hc=-600 meters is calculated according to the calculation formula of the critical buried depth Hc mentioned above.

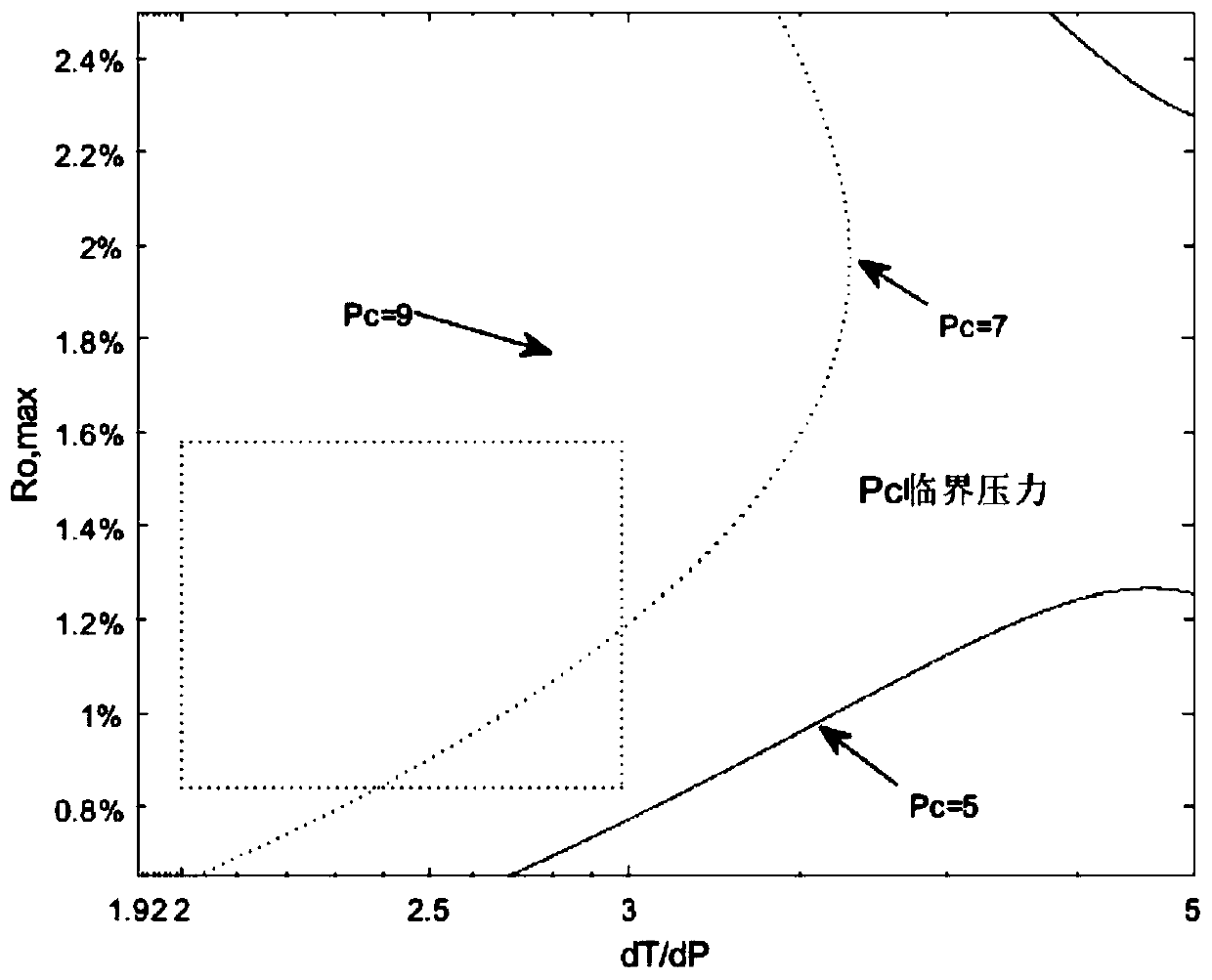

[0048] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical pressure Pc=6.75 MPa is calculated according to the above formula for calculating the critical pressure Pc.

[0049] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sampl...

Embodiment approach 2

[0051] The vitrinite maximum reflectance R of coal obtained during exploration and development 0,max =1.58, the geothermal gradient is 2.5°C / hm, and the pressure gradient is 1.0MPa / hm.

[0052] The method comprises the steps of:

[0053] Calculate the temperature-pressure gradient ratio according to the geothermal gradient and pressure gradient of the coal sample

[0054] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical buried depth Hc=-880 meters is calculated according to the calculation formula of the critical buried depth Hc mentioned above.

[0055] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical pressure Pc=9.74 MPa is calculated according to the above formula for calculating the critical pressure Pc.

[0056] According to the maximum reflectance of vitrinite and temperature-pressure gradient ratio of the coal sa...

Embodiment approach 3

[0058] The vitrinite maximum reflectance R of coal obtained during exploration and development 0,max =2.3, the geothermal gradient is 2.5°C / hm, and the pressure gradient is 1.0MPa / hm.

[0059] The method comprises the steps of:

[0060] Calculate the temperature-pressure gradient ratio according to the geothermal gradient and pressure gradient of the coal sample

[0061] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical buried depth Hc=-924 meters is calculated according to the above formula for calculating the critical buried depth Hc.

[0062] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critical pressure Pc=10.4 MPa is calculated according to the above critical pressure calculation formula.

[0063] According to the maximum reflectance of vitrinite and the temperature-pressure gradient ratio of the coal sample, the critica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com