A micro-motor and a fan including the same

A micro-motor and motor housing technology, applied in the field of micro-motors and fans with micro-motors, can solve problems such as easy shaking, vibration and noise, and shortened axial joint height, so as to achieve smooth and stable operation, improve stability, and shaft The effect of increasing the binding height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

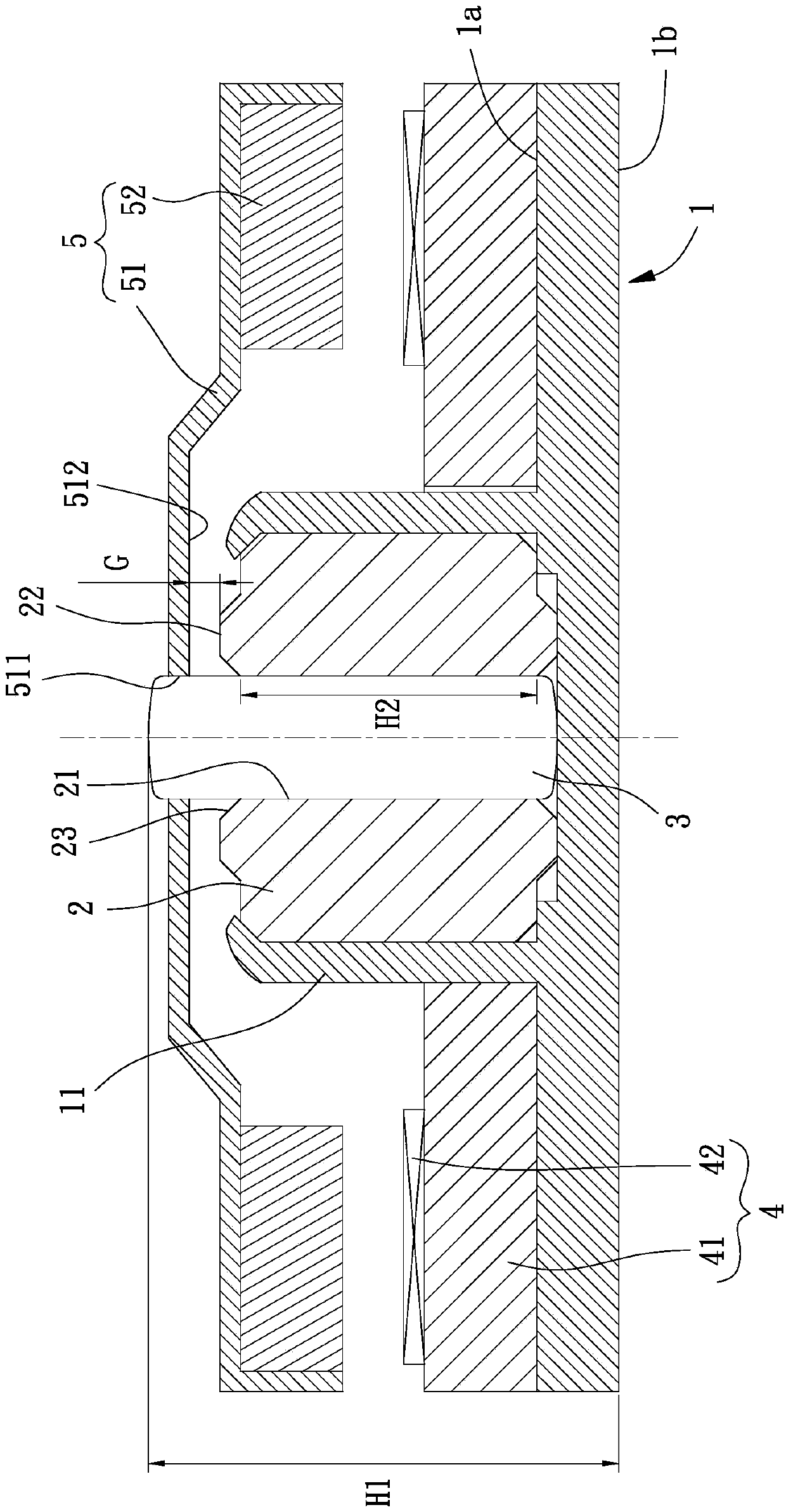

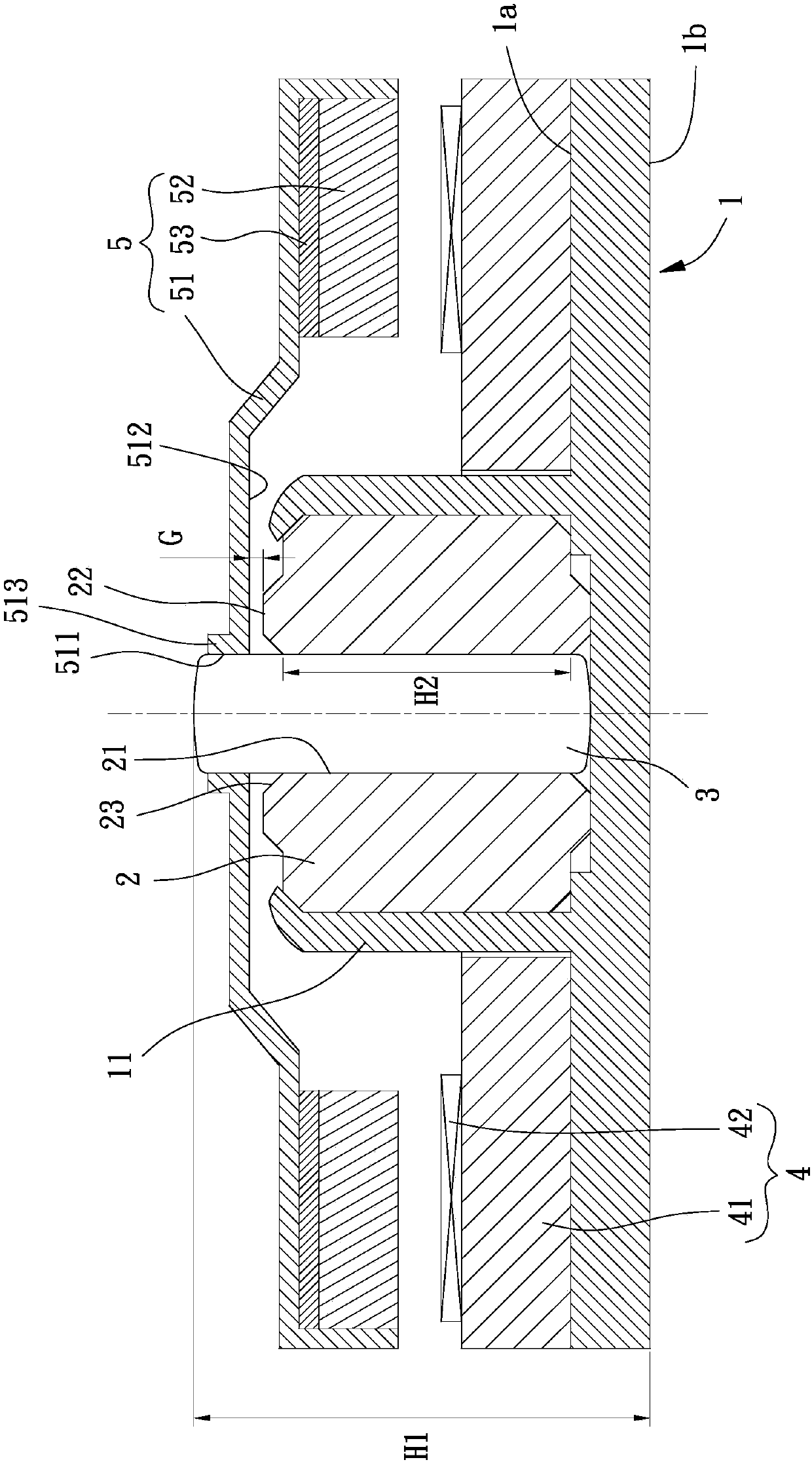

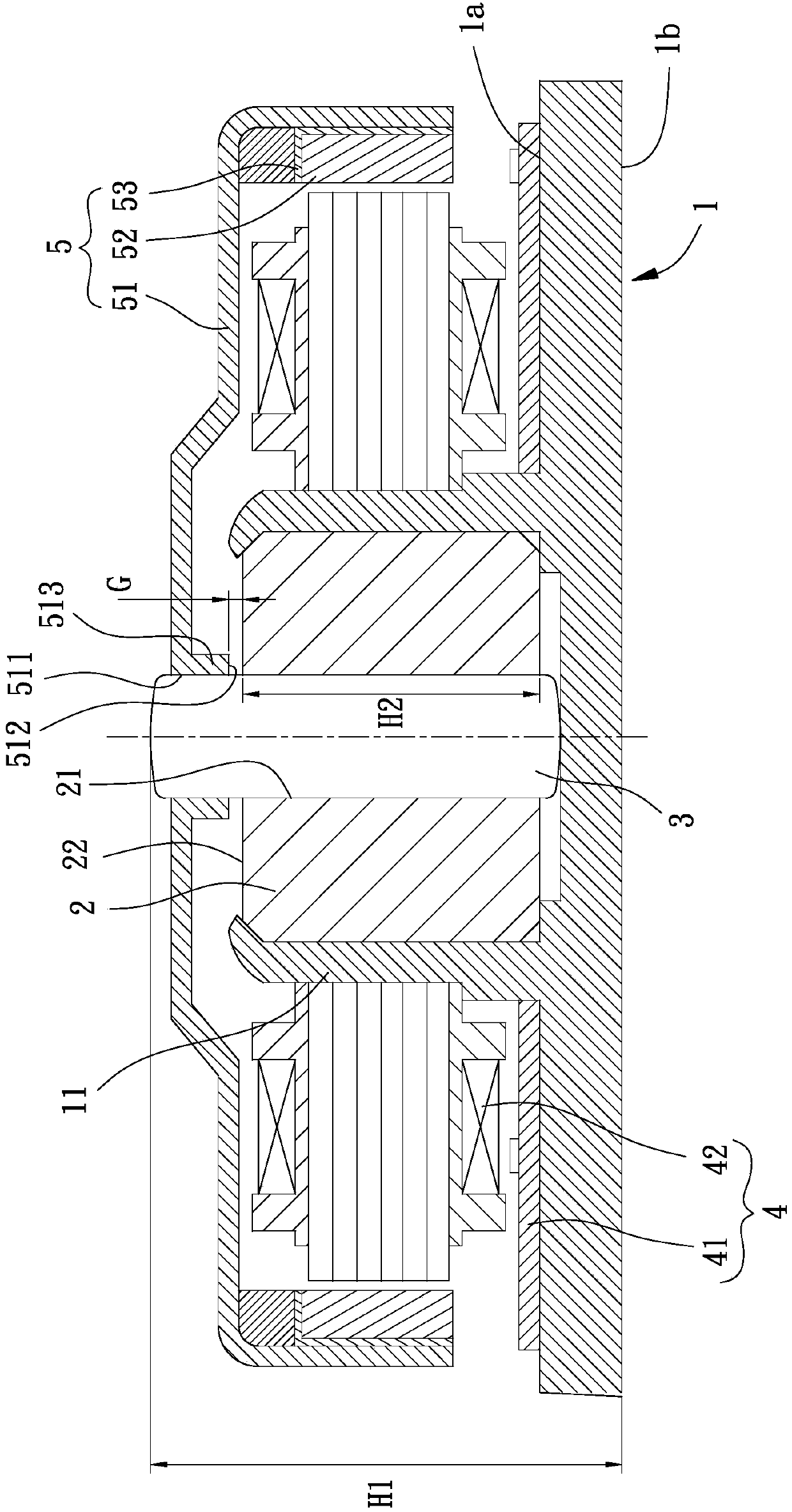

[0040] Please refer to figure 1 , which is the first embodiment of the micro motor of the present invention, the micro motor includes a base 1, a bearing 2, a shaft 3, a stator group 4 and a rotor group 5, the bearing 2 is located on the base 1 , the shaft 3 is rotatably coupled to the bearing 2 , the stator set 4 is coupled to the base 1 , and the rotor set 5 is coupled to the shaft 3 .

[0041] Please refer to figure 2 , the base 1 has an opposite inner surface 1a and an outer surface 1b, the inner surface 1a of the base 1 can be protruded with a shaft tube 11, the shaft tube 11 is used to accommodate the bearing 2; in this embodiment In the example, the shaft tube 11 is integrally connected with the inner surface 1a, so the base 1 can be integrally injection-molded with plastic material to improve the manufacturing convenience of the base 1. Although the base is integrally injection-molded in this embodiment 1 as an example, but not limited thereto.

[0042] Please refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com