Wet mixing granulator sprayed with Teflon

A wet granulator and wet mixing technology, applied in the direction of granulation in static tanks/tanks, can solve problems such as unfavorable cleanliness powder particle production requirements, affecting the service life of the overall structure, affecting the airtightness of the overall structure, etc. To achieve the effect of smooth and stable operation, simple structure, and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

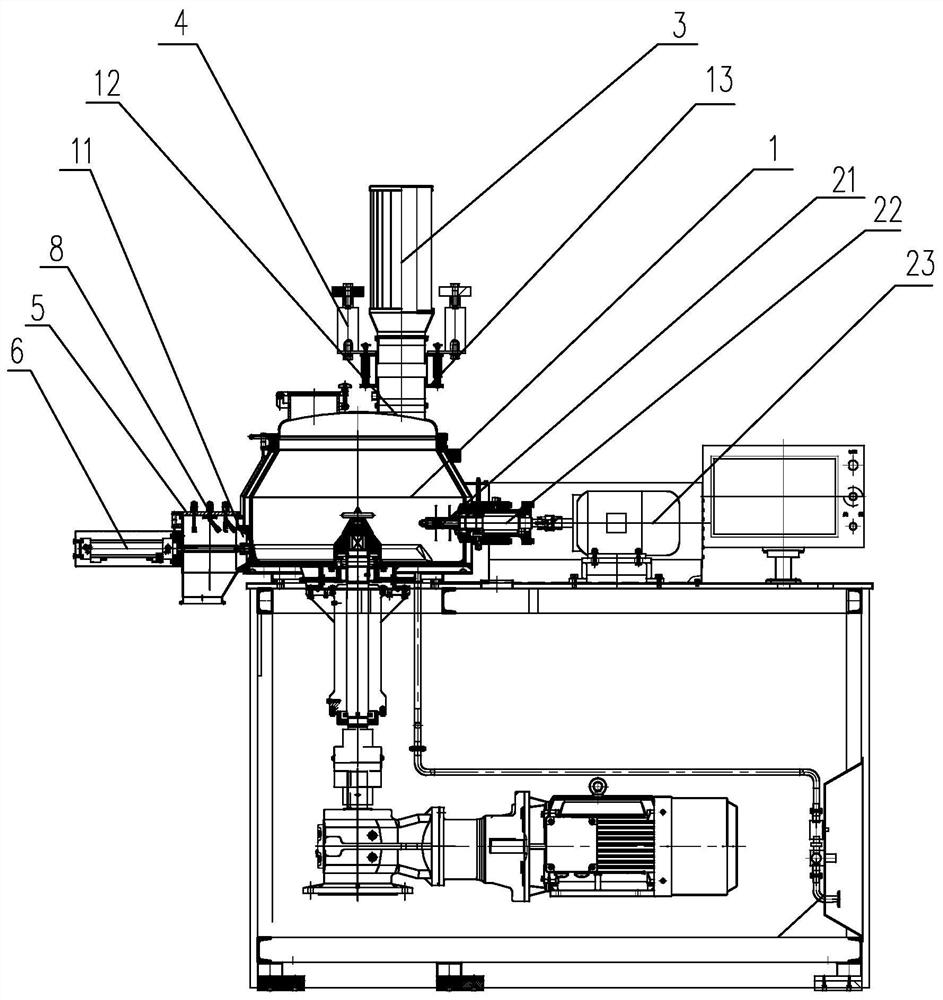

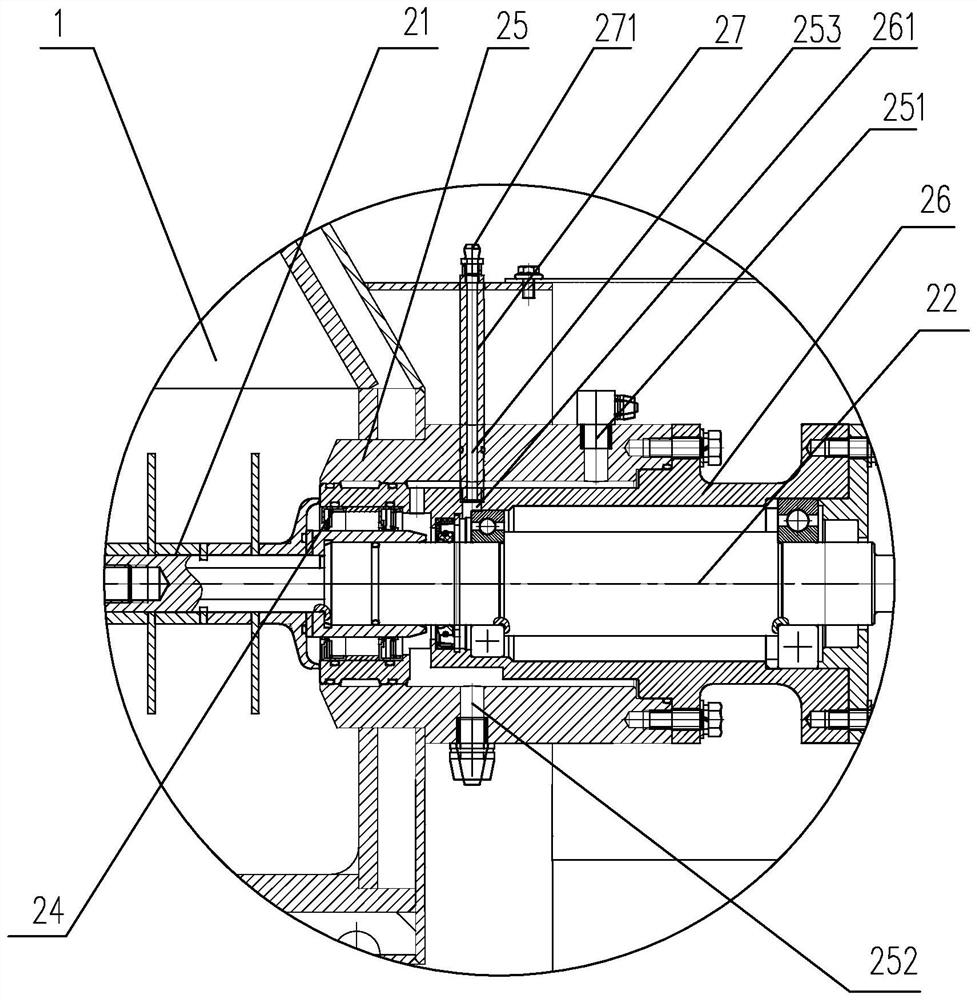

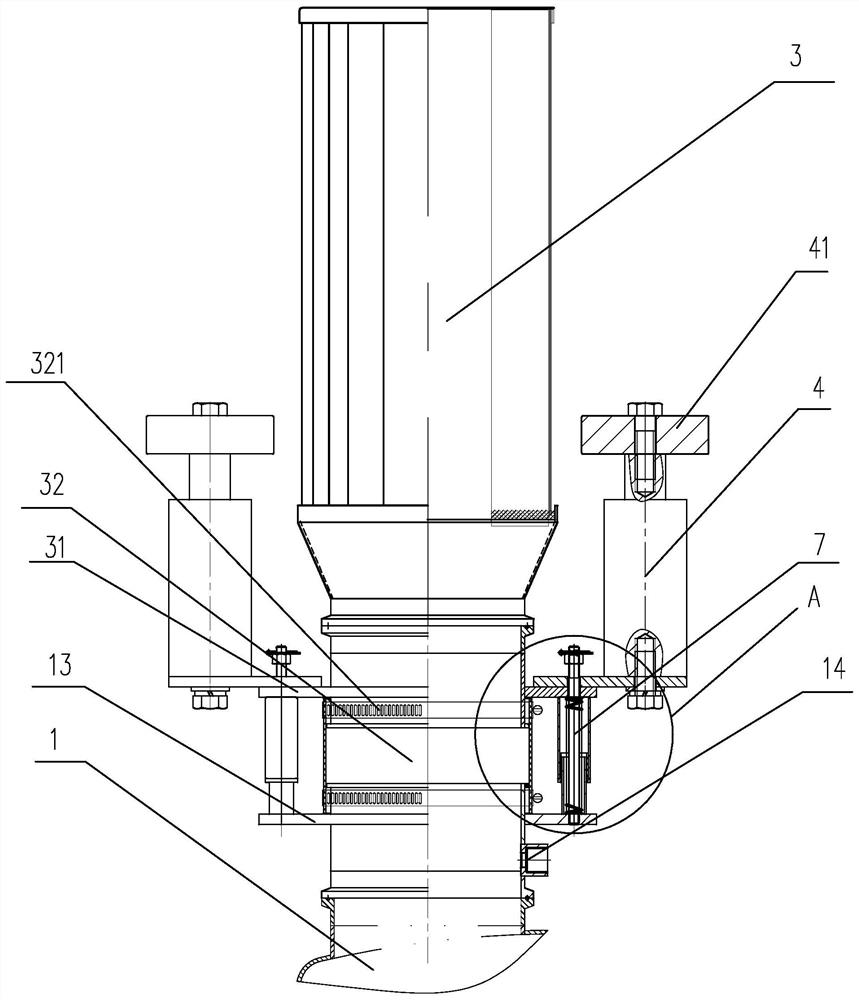

[0030] The embodiment of the wet mixing granulator of spraying Teflon of the present invention is for example Figure 1 to Figure 6Shown: includes a tank body 1, the tank body 1 is provided with a granulation knife, the tank body 1 is provided with a feed port 11 and a feed port 12, and the granulation knife includes a drive motor 23, a coupling 22 and a cutter body 21, the cutter body 21 is connected to the output end of the drive motor 23 through a coupling 22, the coupling 22 is connected to the tank body 1 through a connecting seat 25, and the connecting seat 25 is connected to the coupling 22 A rotating shaft cover 24 is arranged between them, and a closed cover 26 is set outside the coupling 22, and the closed cover 26 and the coupling 22 are connected by bearings, and the connecting seat 25 is sleeved on the closed The cover 26 is fixedly connected with the closed cover 26. The closed cover 26, the connecting seat 25 and the rotating shaft cover 24 are combined in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com