Protective method and device for liquid-cooled liquid leakage of communication equipment

A technology for communication equipment and liquid cooling, which is used in electrical equipment structural parts, support structure installation, cooling/ventilation/heating renovation, etc. It can solve problems such as power supply short circuit, service damage, signal short circuit, etc., and reduce the scope of influence. , The effect of saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

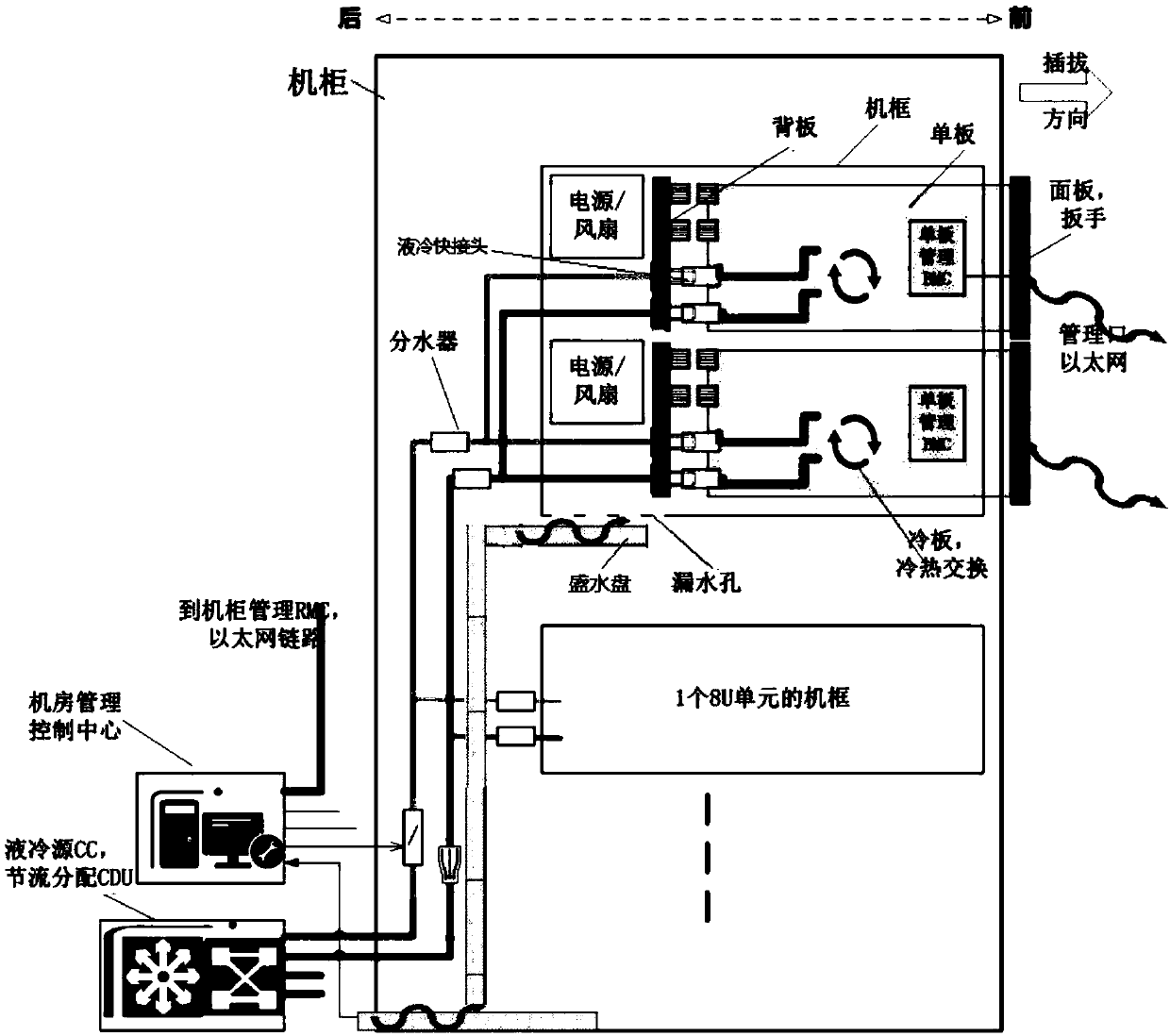

[0042] The invention provides a method and device for protecting liquid cooling leakage of communication equipment, which reduces the possibility of signal short circuit and power supply short circuit caused by liquid cooling leakage, and reduces the range affected by local leakage faults.

[0043] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described below are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

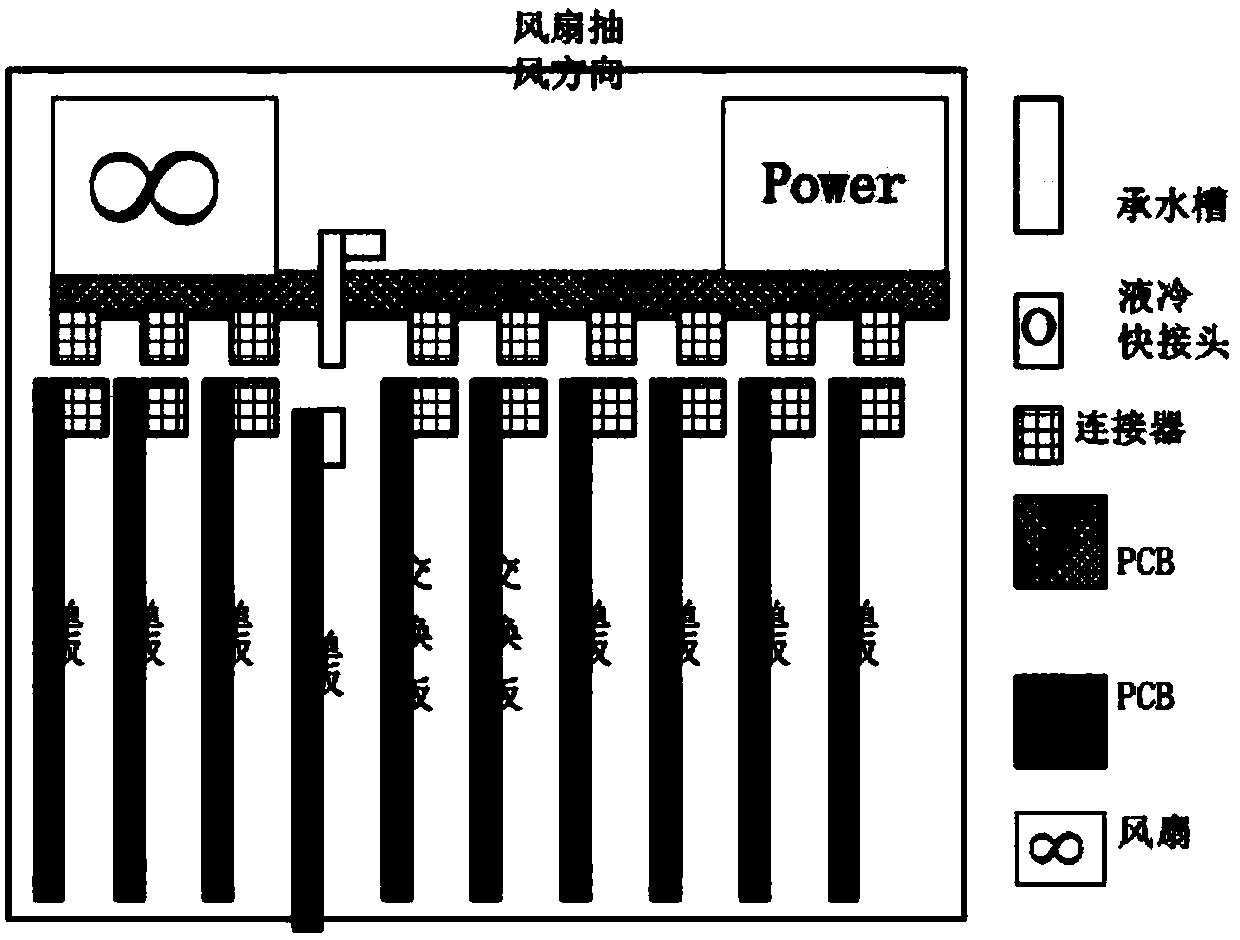

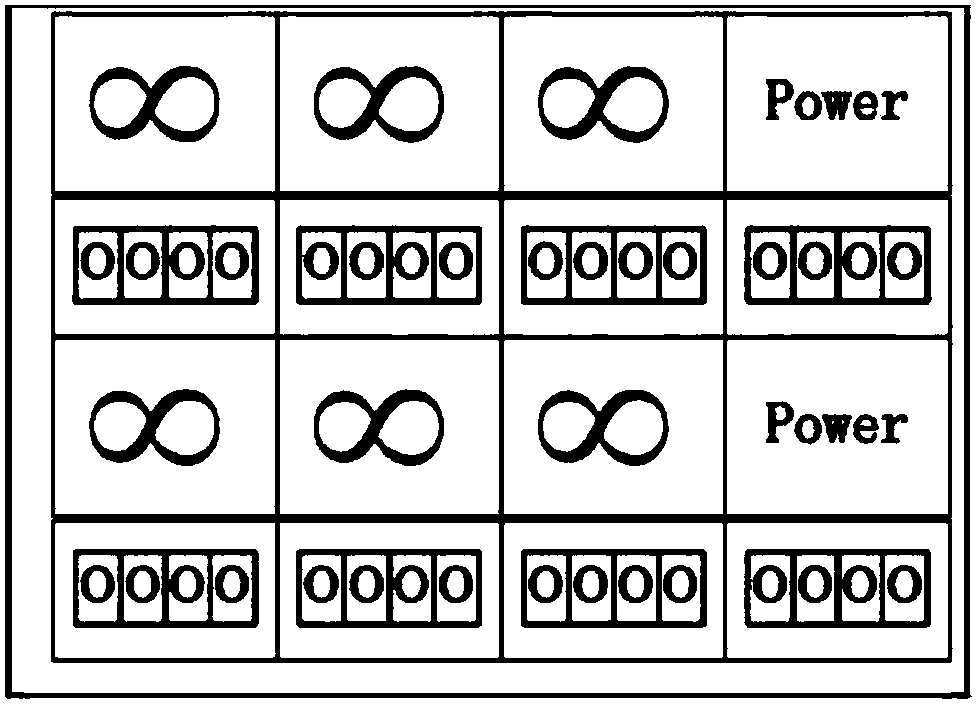

[0044] Such as image 3 , 4a , 4b and 4c, the liquid-cooled leakage protection device of the communication equipment of the present embodiment includes: a cabinet 1; a machine frame 2, a plurality of machine frames 2 are distributed in the height direction of the cabinet 1; Two layers of single boards are distributed in a machine frame 2 of the embodiment, and each l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com