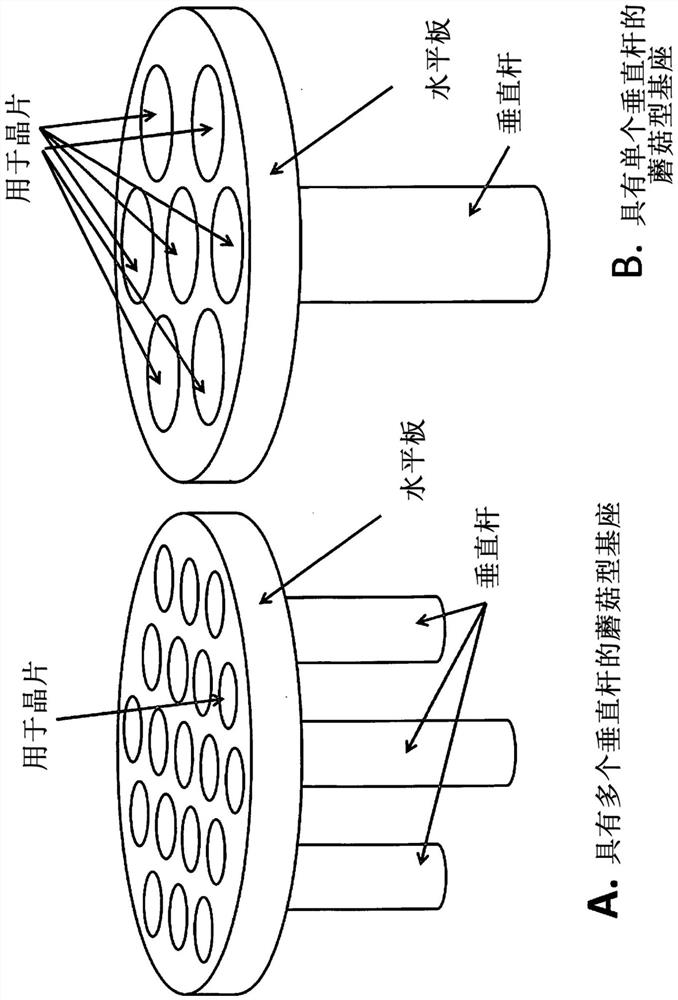

base

A base and equipment technology, applied in crystal growth, from chemically reactive gases, coatings, etc., can solve problems affecting growth efficiency and growth quality, low film growth efficiency, gas circulation, etc., to avoid suspension problems, The effect of improving growth uniformity, good film uniformity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

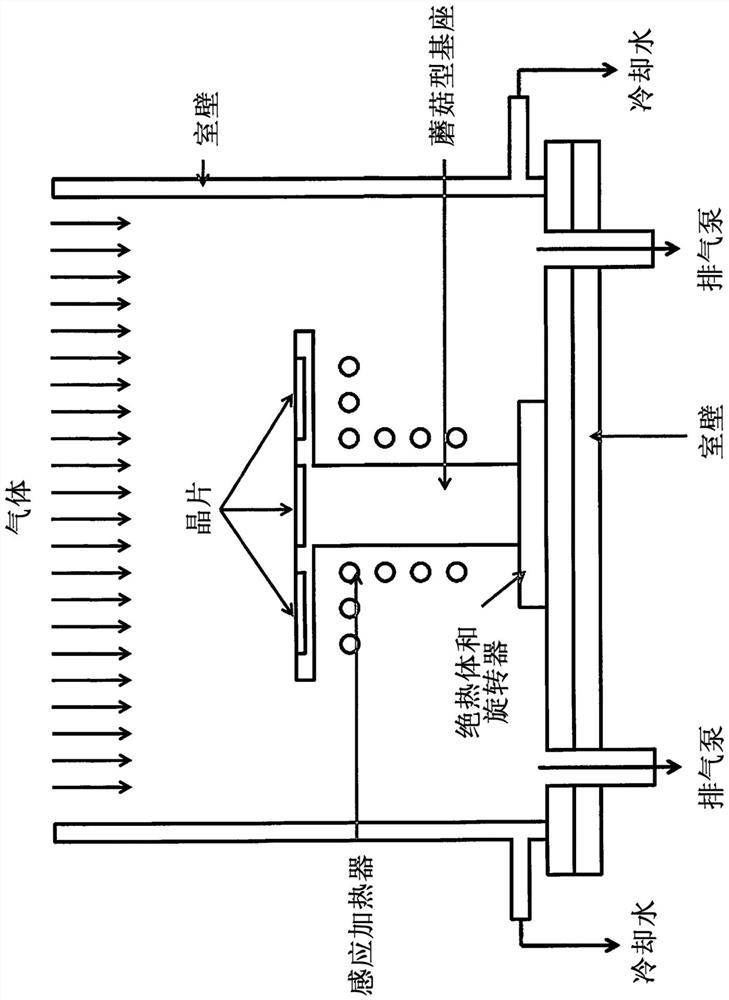

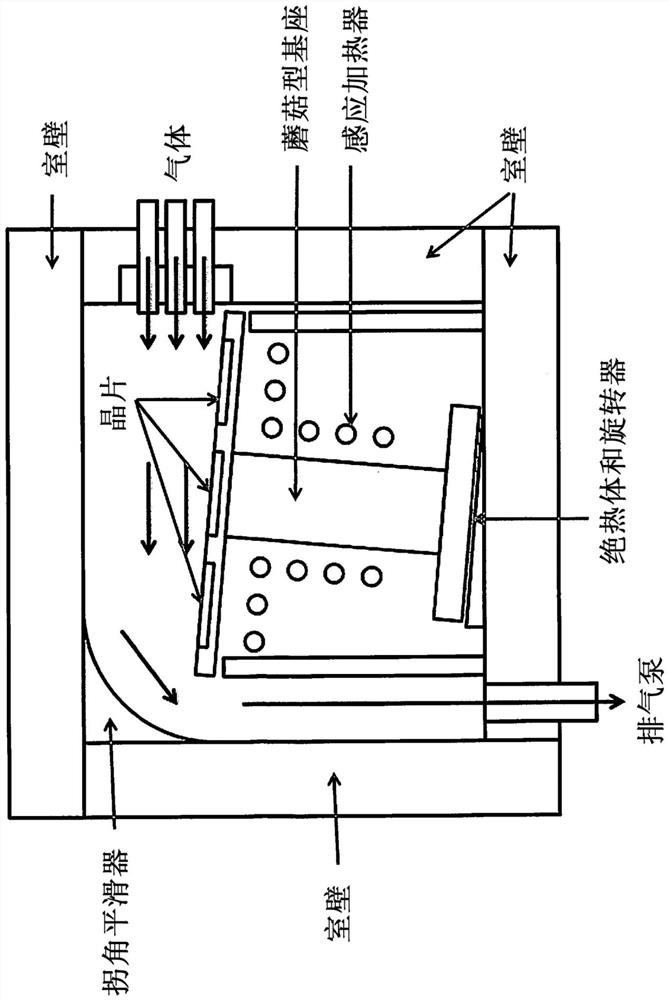

Method used

Image

Examples

Embodiment Construction

[0035] introduction

[0036] Additional more detailed descriptions are provided below.

[0037] References cited herein are incorporated by reference in their entirety.

[0038] Chemical vapor deposition (CVD), metalorganic chemical vapor deposition (MOCVD), metalorganic vapor phase epitaxy (MOVPE) and organometallic vapor phase epitaxy (OMVPE) are methods known in the art, and performing these methods is also known in the art. See, eg, Chemical Vapor Deposition: Principles and Applications, Hitchman, Jensen (editor), 1993. See also, eg, U.S. Patent Nos. 9,299,595, 8,709,162, 7,126,090, 6,321,680, 6,031,211, 5,964,943, 5,835,678, 5,759,263, 5,700,725; and U.S. Patent Publication No. 2010 / 0199914 No. 2008 / 0036155 and other references cited herein. See also JP2013115264 and CN103436862. Methods of fabricating reactors for carrying out these methods are known in the art.

[0039] In one embodiment, the gaskets, fluid manifolds or any other components described in US Pat. No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com