Preparation method and application of a molybdenum disulfide composite bifunctional electrocatalyst

A composite material, molybdenum disulfide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, electrodes, etc., can solve the problems of insufficient conductivity, low atom utilization rate, hindering the application of molybdenum disulfide, etc., and achieve cost The effect of low, improved atom utilization, and enriched catalytic active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

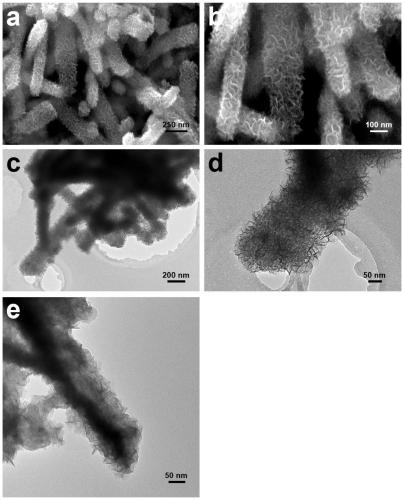

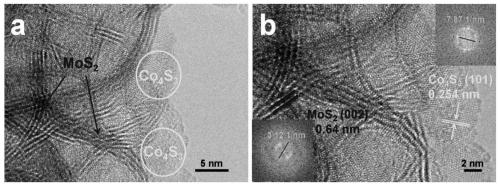

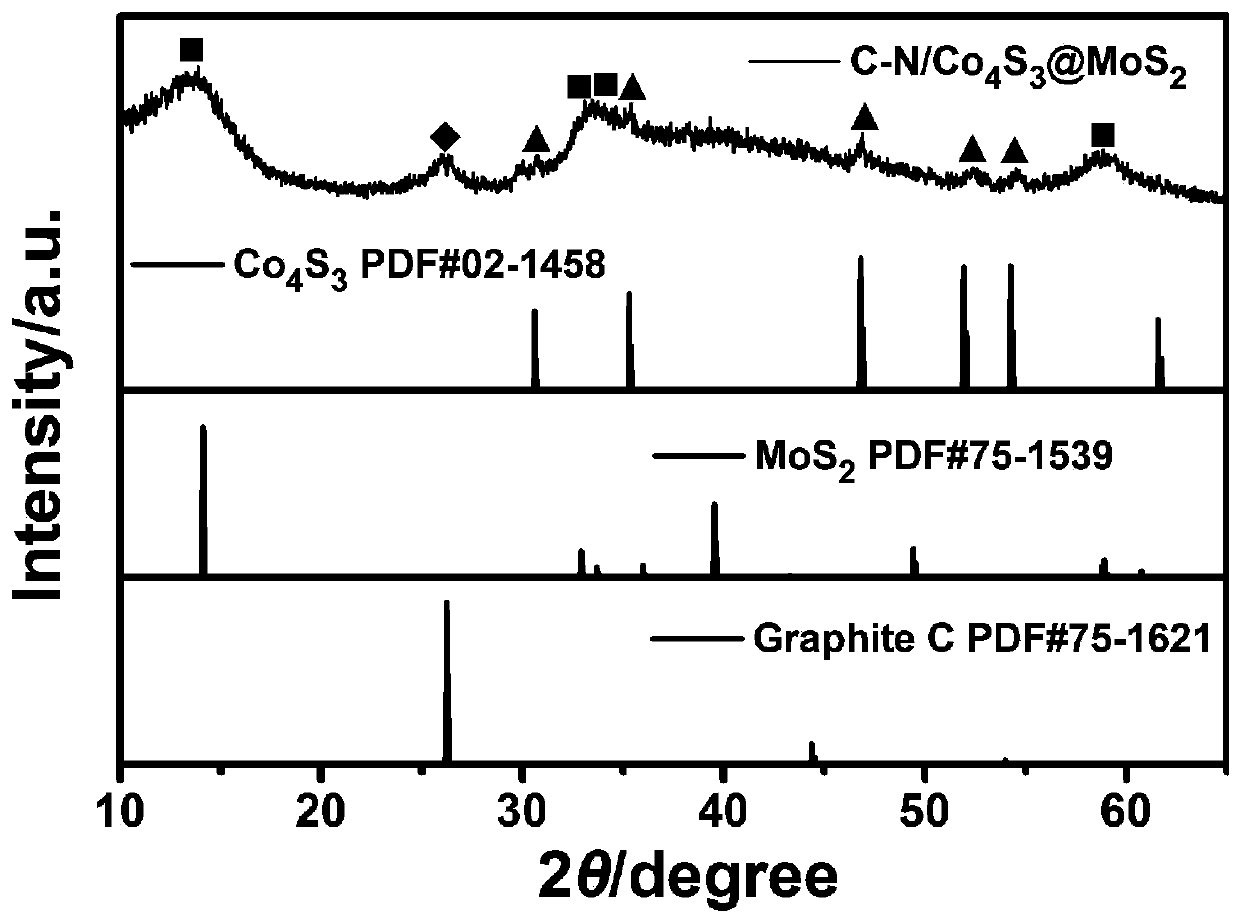

[0033] A kind of bifunctional electrocatalyst of molybdenum disulfide composite material, its preparation method comprises the steps:

[0034] (1) Dissolve 0.075 moles of dimethylimidazole and 0.02 moles of zinc nitrate hexahydrate in 150 ml of methanol respectively, mix them together after the two are completely dissolved, then stir at room temperature for 24 hours, and finally centrifuge and dry Overnight, get ZIF-8;

[0035] (2) 0.075 moles of dimethylimidazole and 0.02 moles of cobalt nitrate hexahydrate and 0.5 grams of ZIF-8 obtained in step (1) were dissolved in 100 milliliters of methanol respectively, and mixed together after the three were completely dissolved , then stirred at room temperature for 24 hours, and finally centrifuged, washed and dried overnight to obtain ZIF-8@ZIF-67;

[0036] (3) Take the ZIF-8@ZIF-67 obtained in step (2) and place it in a tube furnace. In an argon atmosphere, raise it to 920°C at a rate of 2°C / min, and then keep it at a constant tem...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is:

[0041] The taking amount of dimethylimidazole described in step (1) is 0.03 mole, and the taking amount of described zinc nitrate hexahydrate is 0.008 mole;

[0042] The taking amount of dimethylimidazole described in step (2) is 0.03 mole, and the taking amount of described cobalt nitrate hexahydrate is 0.008 mole, and the taking amount of described ZIF-8 is 0.2 gram;

[0043] After placing ZIF-8@ZIF-67 in the tube furnace in step (3), in an argon atmosphere, the temperature is raised to 800°C at a rate of 2°C / min;

[0044] The amount of C-N / Co described in step (4) is 6 mg, the amount of N, N-dimethylformamide is 15 milliliters, and the amount of ammonium tetrathiomolybdate added is 14.9 mg, The addition amount of described hydrazine hydrate is 0.36 milliliters.

[0045] Others are the same as embodiment 1.

Embodiment 3

[0047] The difference between this embodiment and embodiment 1 is:

[0048] The taking amount of dimethylimidazole described in step (1) is 0.045 mole, and the taking amount of described zinc nitrate hexahydrate is 0.012 mole;

[0049] The taking amount of dimethylimidazole described in step (2) is 0.045 mole, and the taking amount of described cobalt nitrate hexahydrate is 0.012 mole, and the taking amount of described ZIF-8 is 0.3 gram;

[0050] The amount of C-N / Co described in step (4) is 9 mg, the amount of N, N-dimethylformamide is 15 milliliters, and the amount of ammonium tetrathiomolybdate added is 22.3 mg, The addition amount of described hydrazine hydrate is 0.54 milliliters.

[0051] Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com