Fillet Welding Method and Fillet Fittings of Composite Plates

A composite plate and fillet welding technology, which is applied to welding accessories, welding equipment, arc welding equipment, etc., can solve the problems of not meeting the needs of special size projects, short service life of anti-corrosion coating, and many welding layers and passes. , to achieve the effect of shortening the equipment manufacturing cycle, improving the life of the equipment and reducing the cost of equipment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

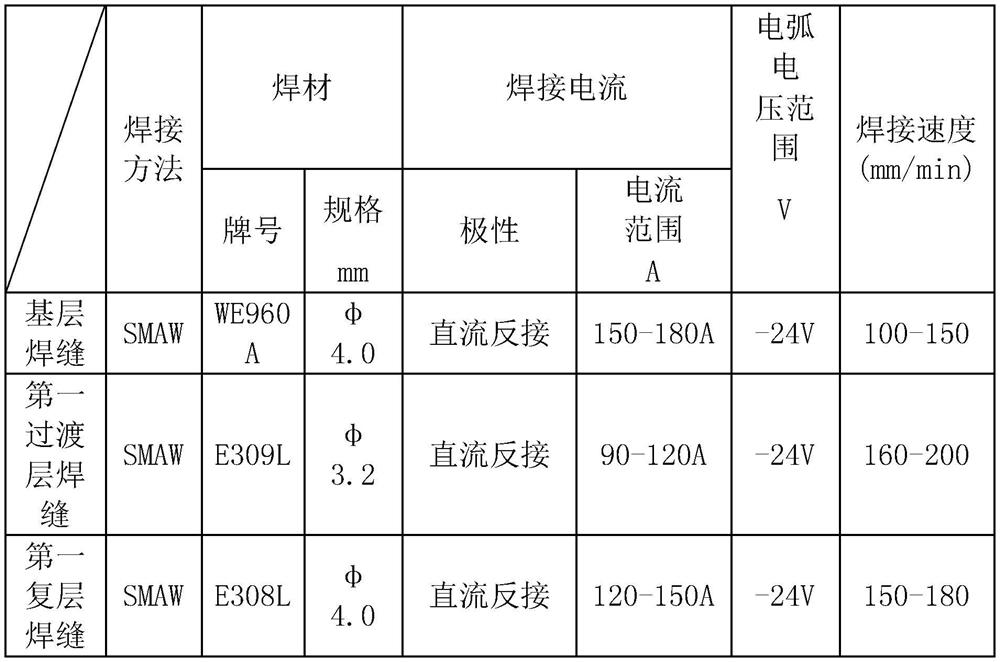

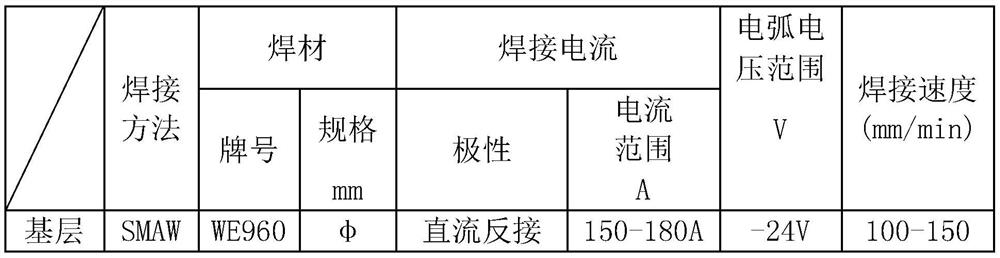

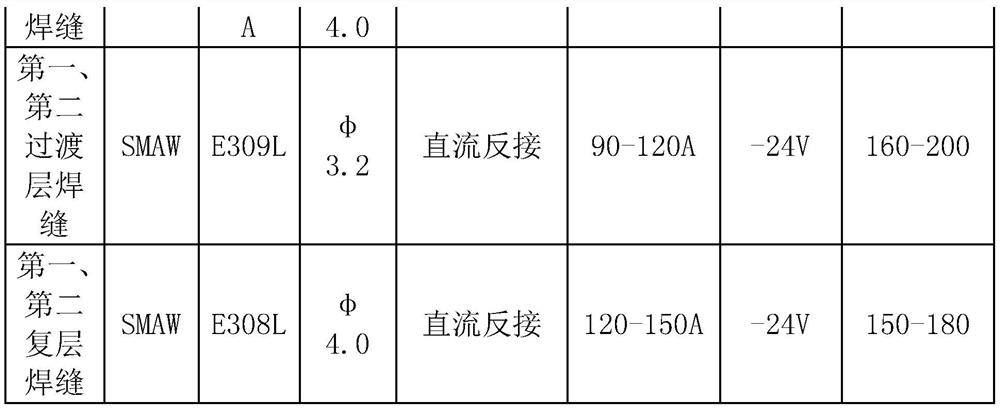

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0038] refer to figure 1 , 2 , the fillet welding method for composite panels according to the first embodiment of the present invention is used for welding the first composite panel 100 and the second composite panel 200 . Wherein, the first clad plate 100 includes the first low alloy steel layer 101 and the first austenitic stainless steel layer 102 composited on the first surface of the first low alloy steel layer 101 by explosive welding; the second clad plate 200 includes the second The low alloy steel layer 201 and the second austenitic stainless steel layer 202 bonded on the first surface of the second low alloy steel layer 201 by explosive welding.

[0039] Both the first composite board 100 and the second com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com