Diamond cutting device

A diamond cutting and diamond technology, which is applied in the field of diamond cutting devices, can solve the problems affecting the overall quality of the diamond cutting surface, the edge chipping of the diamond cutting edge, and the large sawing force, so as to improve the ability to resist chipping and reduce knife marks , Guarantee the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further illustrate that the design and idea provided by the present invention are effective in order to achieve the intended purpose of the invention, below in conjunction with the drawings and preferred embodiments, the specific implementation, structure, features and effects of a diamond cutting device proposed according to the present invention will be described below. , as detailed below

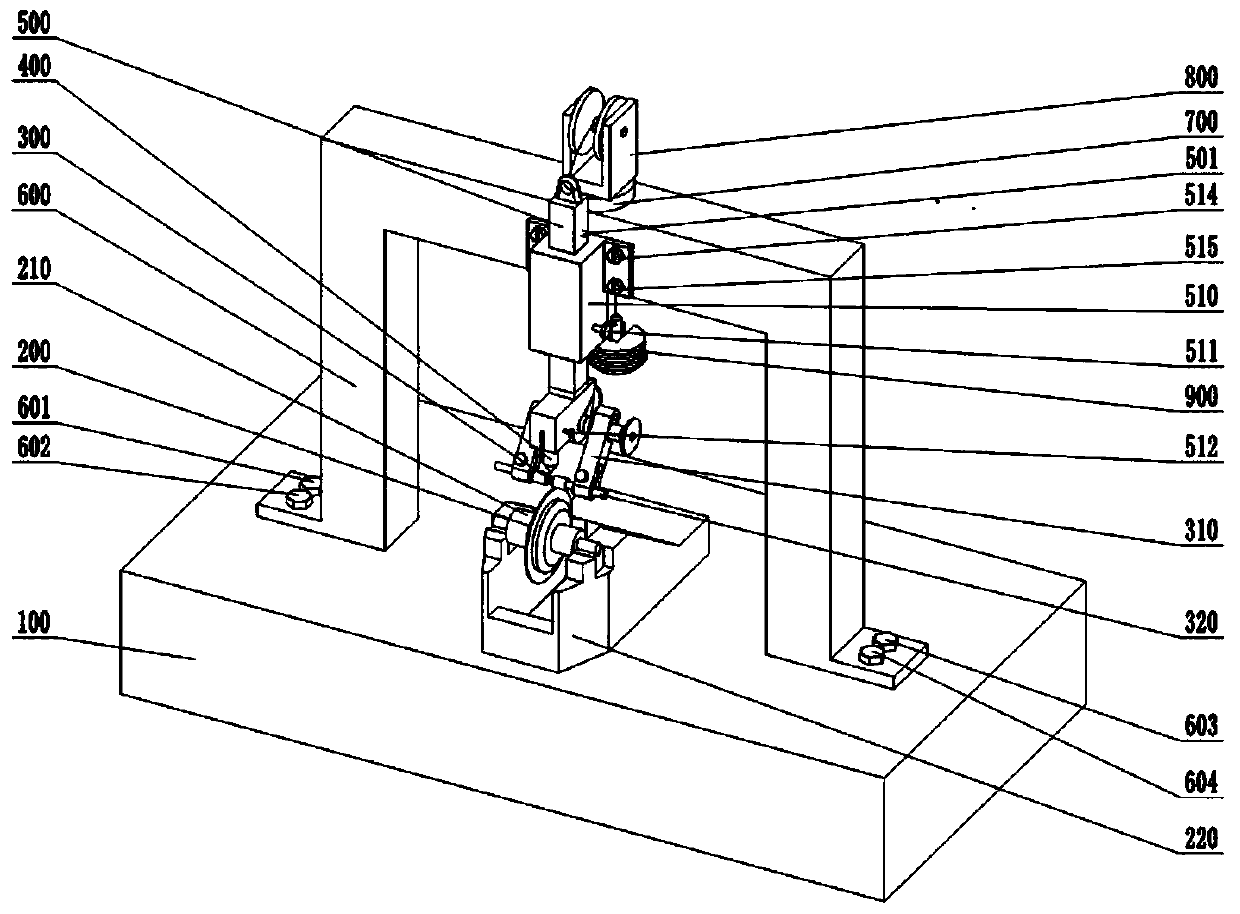

[0021] Such as figure 1 As shown, a diamond cutting device includes a base 100, a saw blade 200, a saw blade clamp 210, a saw blade positioning device 220, a diamond 300, a diamond pose adjustment device 310, a diamond fixing device 320, a laser 400, and a square shaft 500, Square guide rail 510, beam 600, three-way force sensor 700, pulley 800, counterweight adjustment device 900.

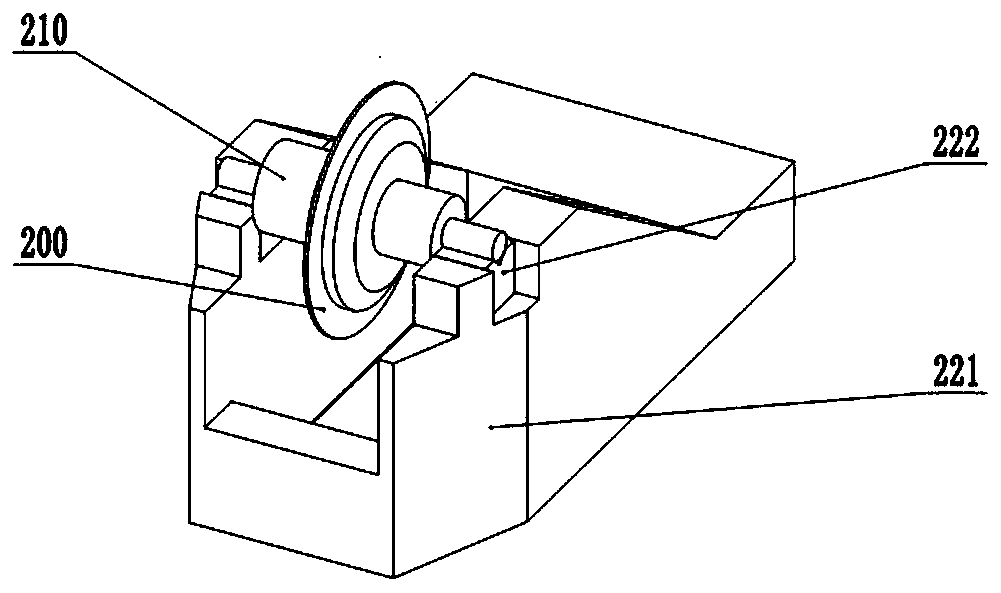

[0022] Such as figure 2 As shown, the saw blade positioning device 220 includes a base 221 and a V-shaped graphite block 222 .

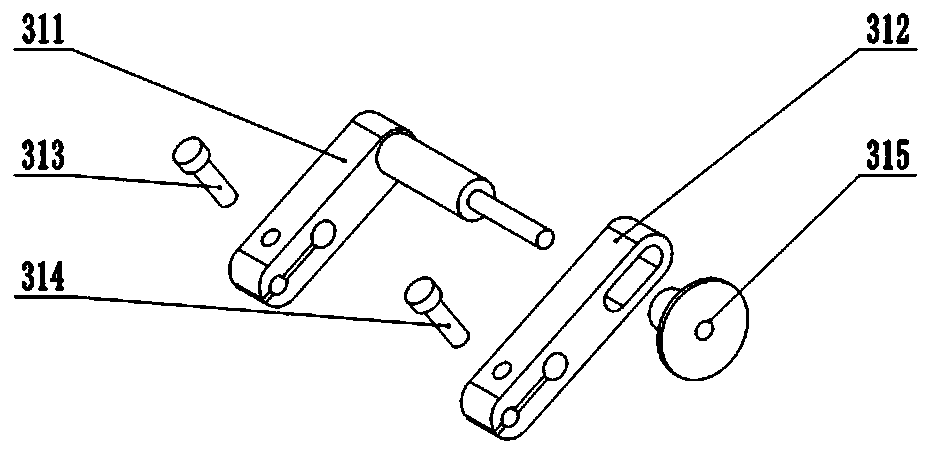

[0023] Such as image 3 , 4 As shown, the diamond pos...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap