High-temperature and high-pressure dyeing machine with double-layer sewage discharging anti-blocking dyeing cylinder

A high-temperature, high-pressure, dyeing cylinder technology, which is applied in the field of dyeing machines, can solve the problems of reducing friction between blockages and bisexual rings, and achieve the effects of improving coloring quality, improving sewage discharge efficiency, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

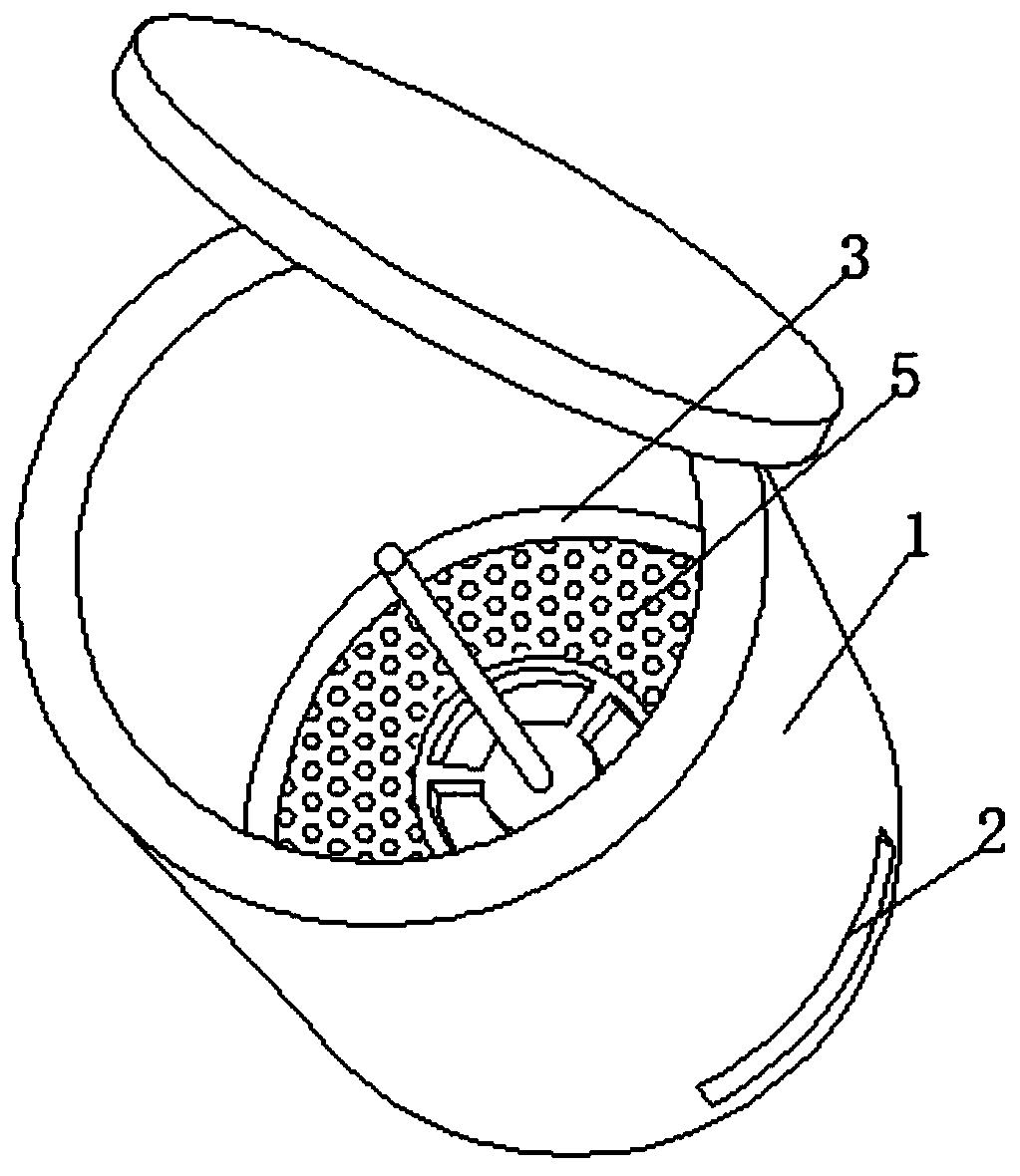

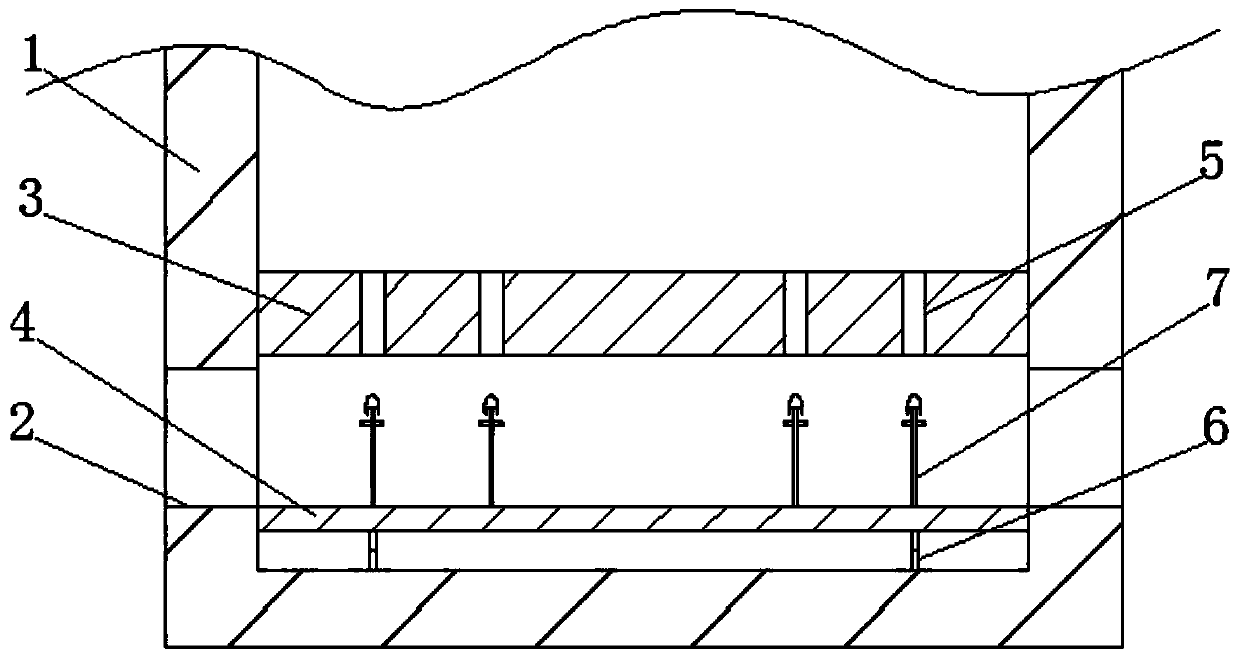

[0046] see Figure 1-2 , a high-temperature and high-pressure dyeing machine with double-layer sewage and anti-blocking dyeing cylinders, including a dyeing cylinder 1 installed on the high-temperature and high-pressure dyeing machine, a plurality of outlets 2 are dug at the inner bottom of the dyeing cylinder 1, and the inner ends of the dyeing cylinder 1 are fixedly connected There is base plate 3, which is located above outlet 2, see Figure 4 , The inner end of the bottom plate 3 is dug with a plurality of evenly distributed sewage holes 5 .

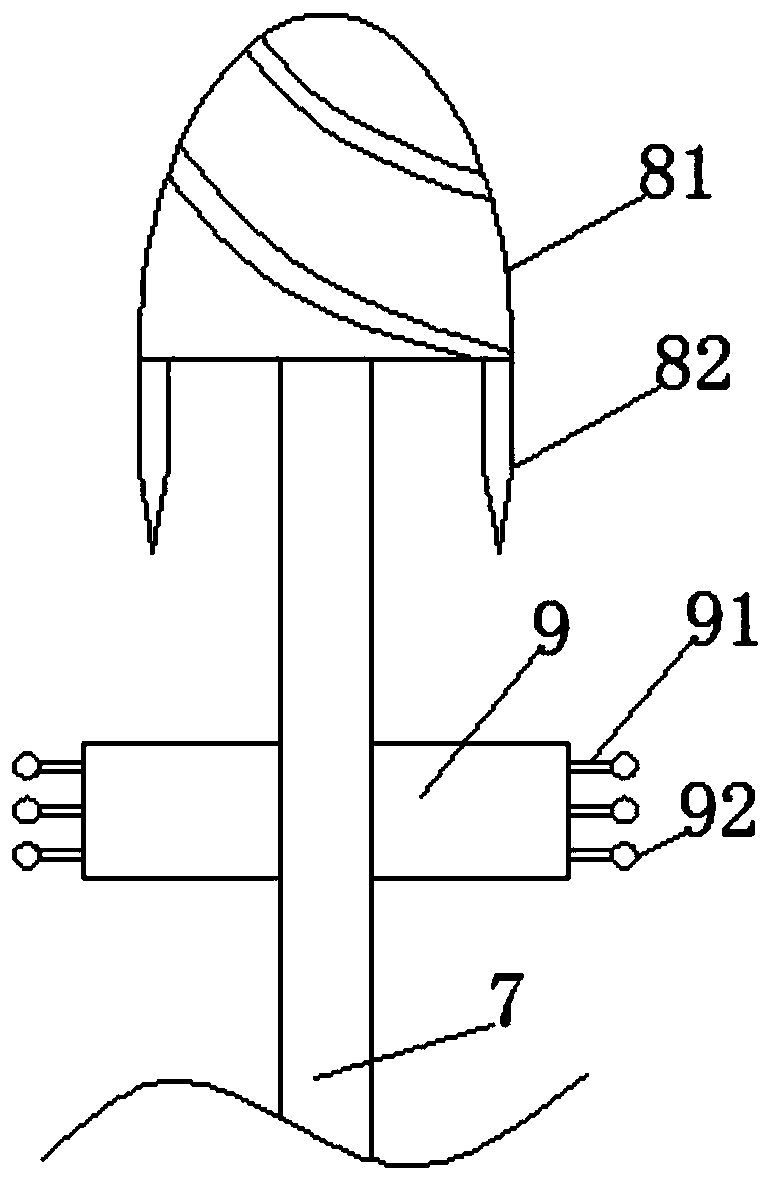

[0047] see Figure 5 , the inner wall of the sewage hole 5 is fixedly connected with a bisexual ring 10, and the inner wall of the sewage hole 5 is dug with a ring groove 11. The inner wall of the bisexual ring 10 and the nozzle are all polished and coated with a 0.2mm self-lubricating coating. On the one hand, it can Reduce the friction loss of the bisexual ring 10, improve the service life of the bisexual ring 10, on the other ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com