Collecting vehicle for garbage sorting

A garbage classification and collection vehicle technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of low work efficiency, limited range of activities, unfavorable garbage centralized classification and recycling, etc., and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

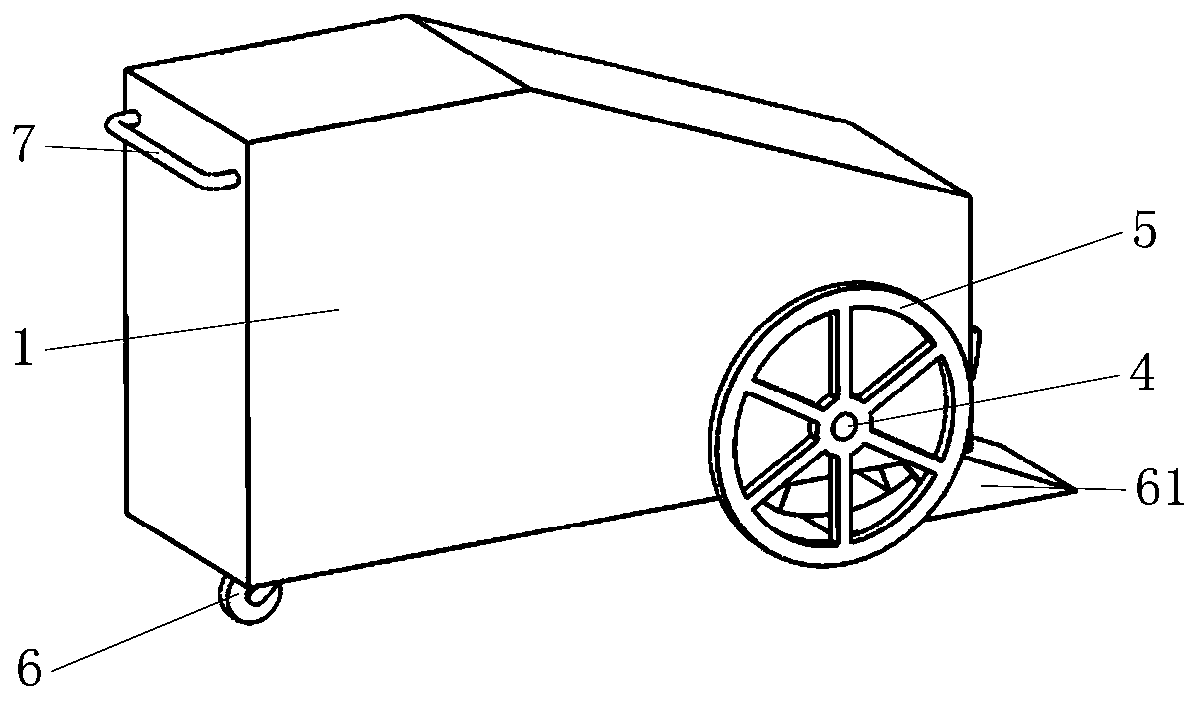

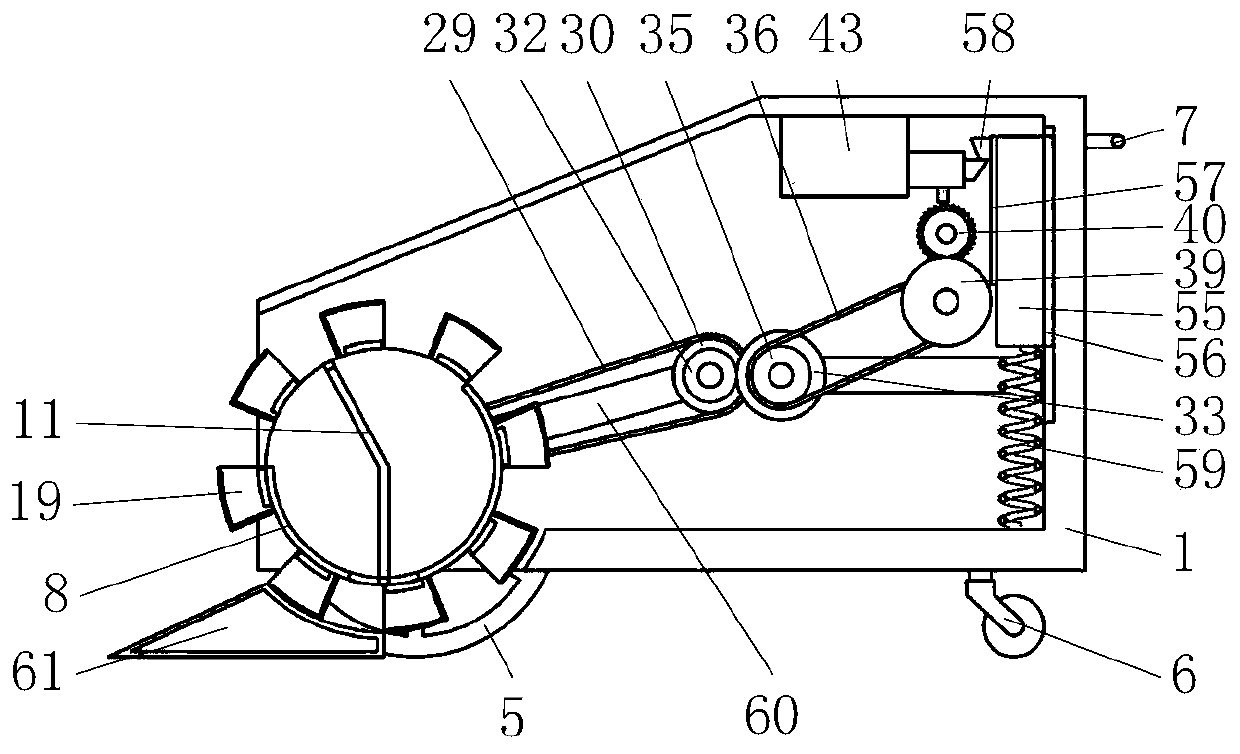

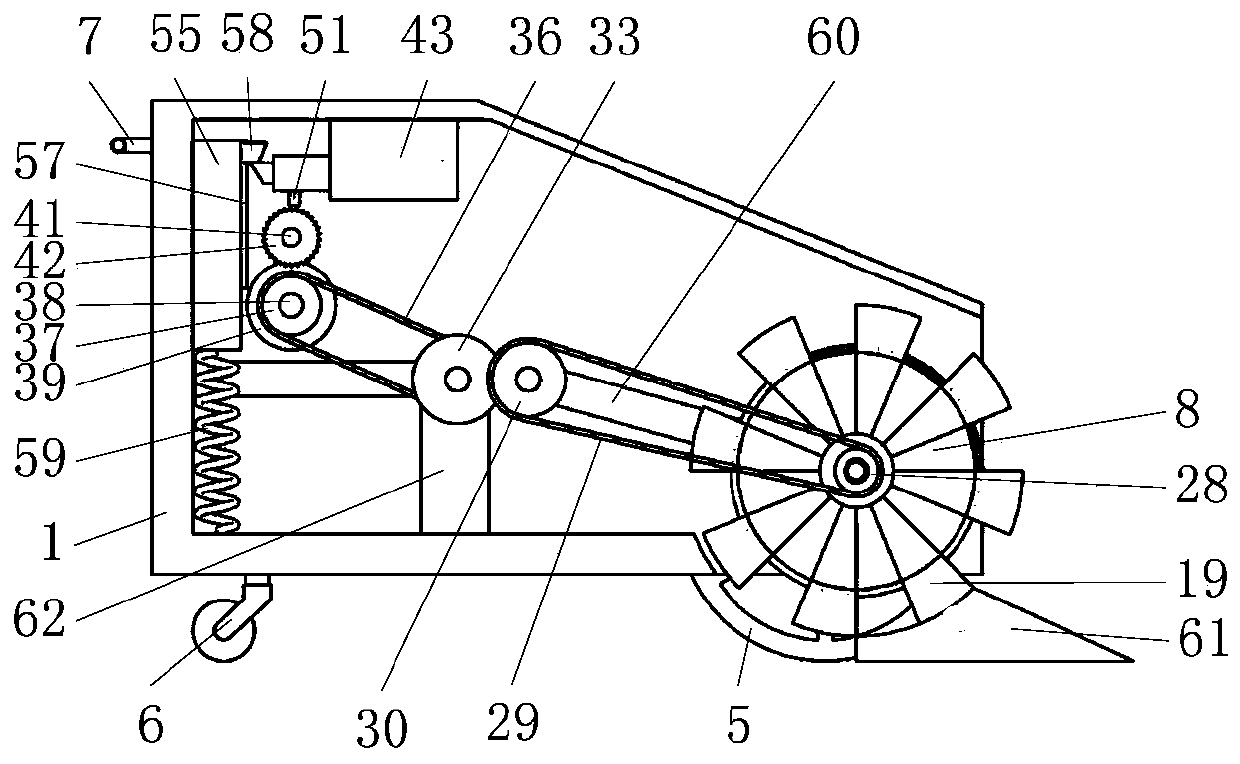

[0044] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0045] like figure 1 , 2 As shown, it includes compartment 1, garbage cylinder 8, V-shaped partition 11, arc-shaped rack 13, shaft A15, rotating ring 17, fan-shaped plate 18, collection mechanism 19, shaft C38, gear C39, shaft D41, ratchet 42. Three-stage expansion plate 43, ordinary expansion plate 51, heavy block 55, straight rack 57, limit block 58, spring E59, pendulum plate 60, wedge-shaped shovel block 61, shaft sleeve 64, electric drive module 62, among which such as image 3 As shown, the lower part of the compartment 1 is equipped with a structure to facilitate its movement; as figure 2 As shown, the middle part of the compartment 1 is equipped with a shaft B31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com