Environmentally-friendly oxidation-imbibition method for increasing recovery rate under zero flowback of fracturing fluid in shale gas well

An environmentally friendly technology for shale gas wells, applied in the fields of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of fracturing fluid flowback, environmental burden, etc., achieve enhanced recovery and simple operation process , the effect of extending the validity period of the transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

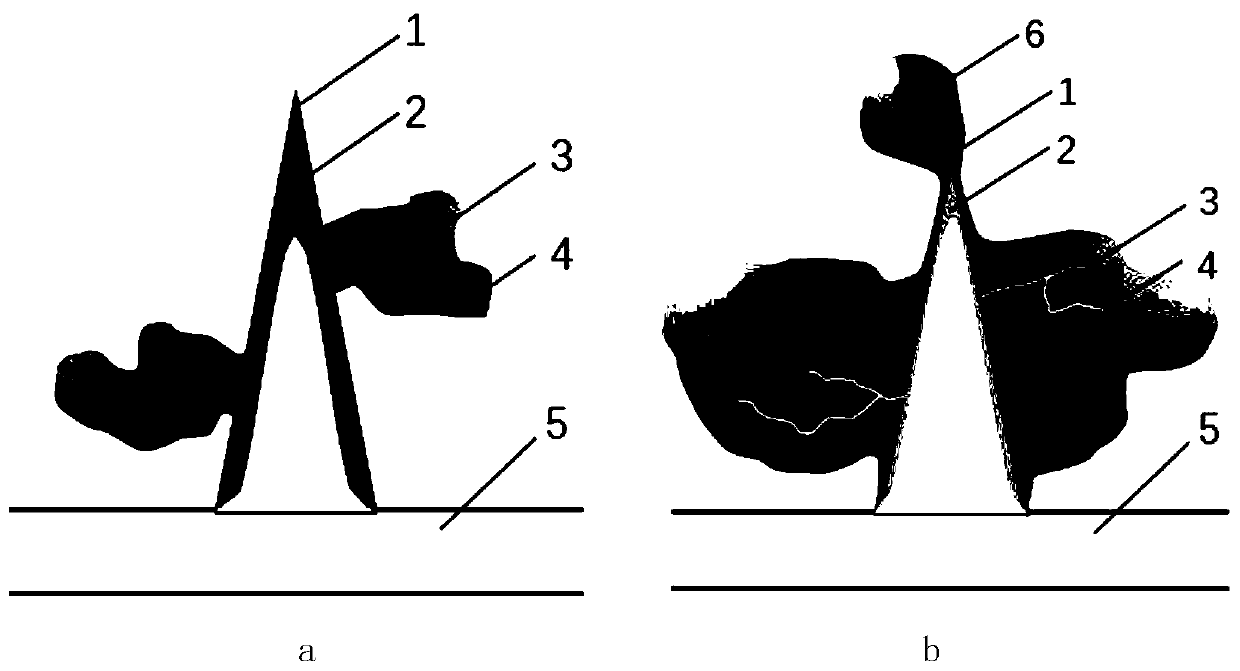

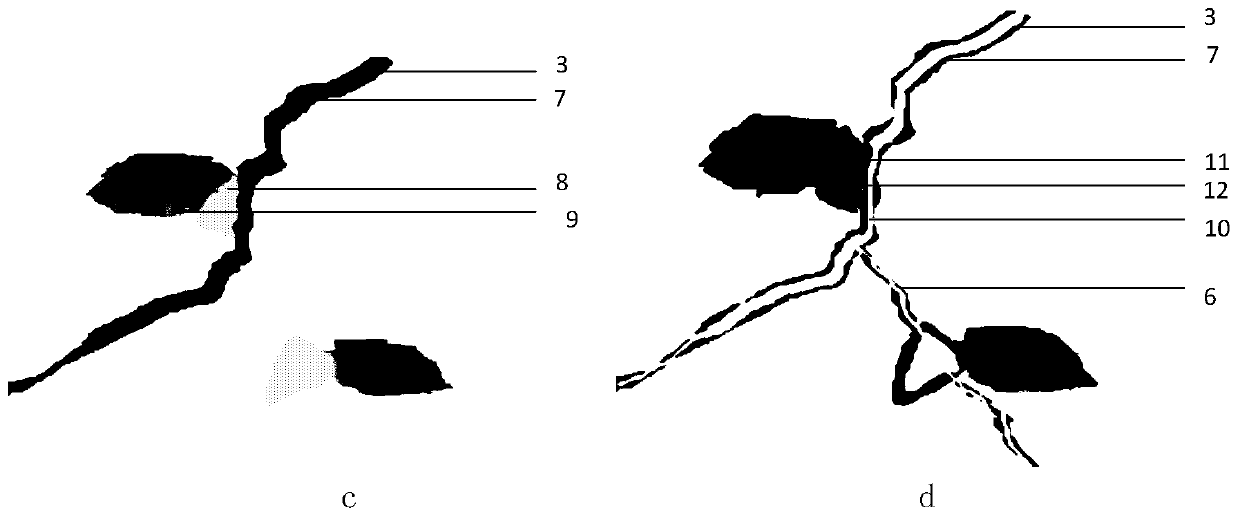

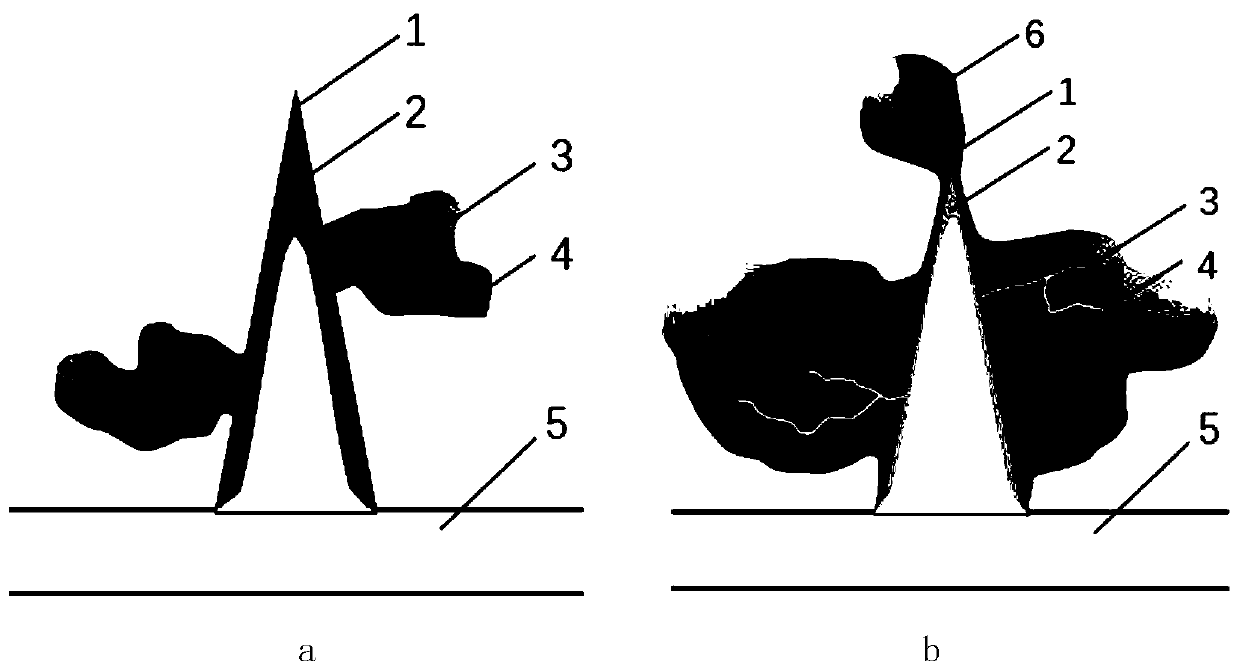

[0021] Attached Figure 1-2 And the examples illustrate the present invention in detail.

[0022] Select a shale gas well to be hydraulically fractured, and determine the relationship between TOC and shale water absorption, and the relationship between TOC and shale water absorption, and the relationship between TOC and shale water absorption, and the relationship between TOC and shale water absorption based on shale gas well logging, core analysis and laboratory tests, and corresponding indoor evaluation data of shale oxidation liquid absorption. Select the relationship between the concentration of oxidant, the rate of oxidizing liquid absorption, and the gas zone suitable for oxidation-infiltration modification.

[0023] The maximum flowback rate of fracturing fluid determined by combining the fracturing operation data and post-fracturing flowback data of other wells in the area is used to determine the configuration of fracturing fluid. According to the determined relationship b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com