Lattice sandwiching structure edgewise compressive testing device

A test device, sandwich structure technology, applied in the testing of machine/structural components, measuring device, using stable tension/pressure to test the strength of materials, etc., can solve the problems of poor operability and low measurement accuracy, and achieve high The effect of precision measurement, improving measurement accuracy and reducing measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0016] a) Measure the test specimen. Measure the width and thickness of any three places within the span of the test specimen, and take the arithmetic mean value. The thickness of the panel shall be the nominal thickness or the average thickness of the same batch of samples. Record the number of unit cells in the cross section.

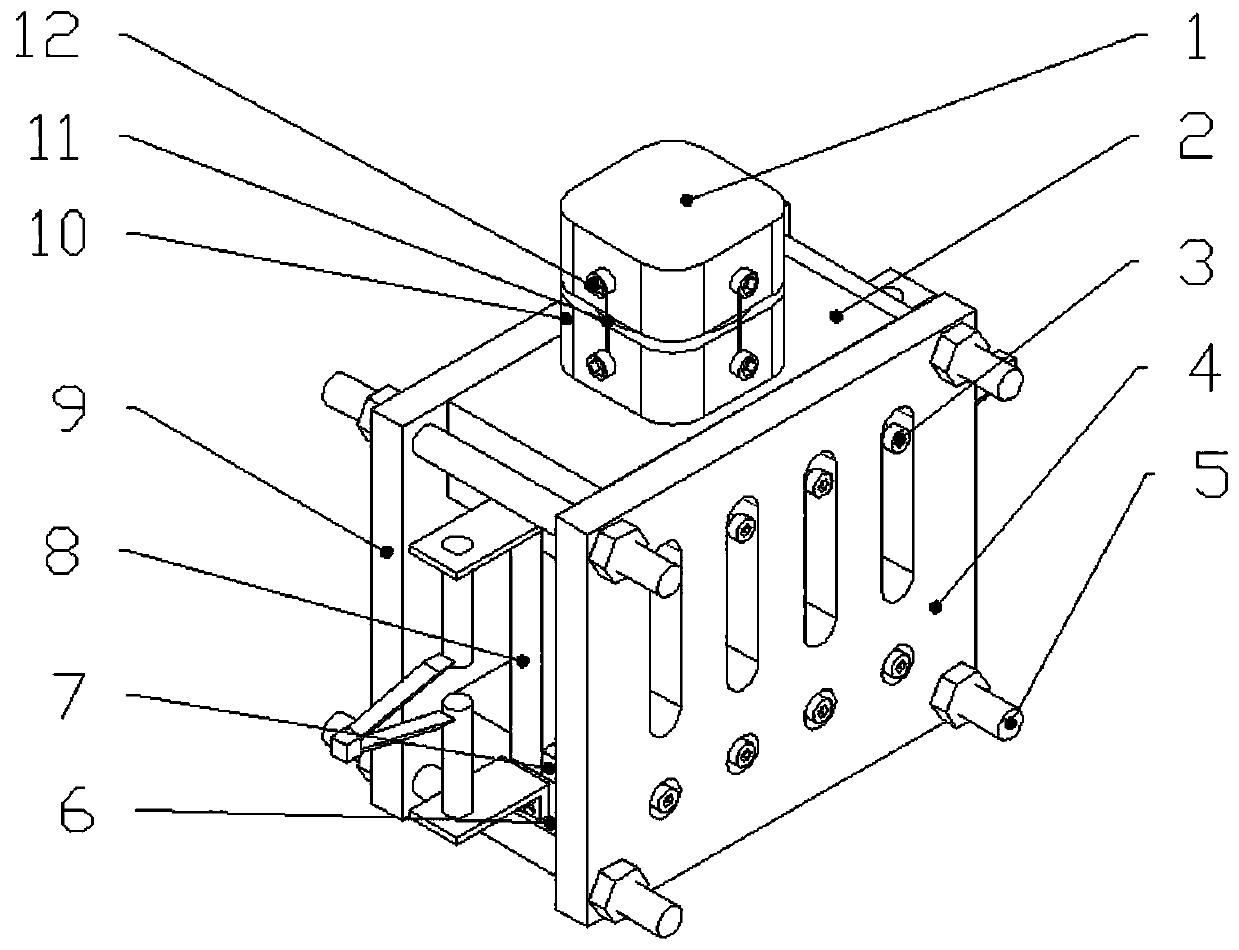

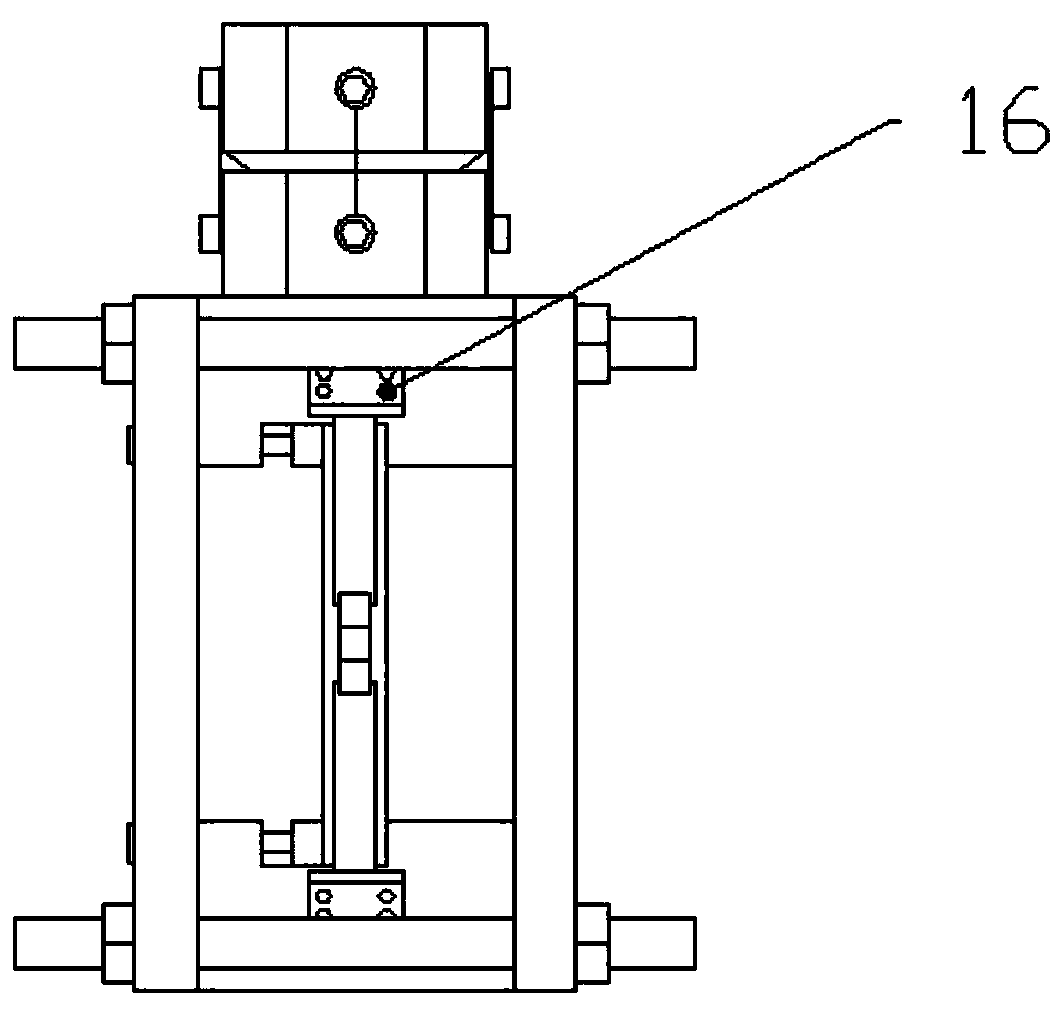

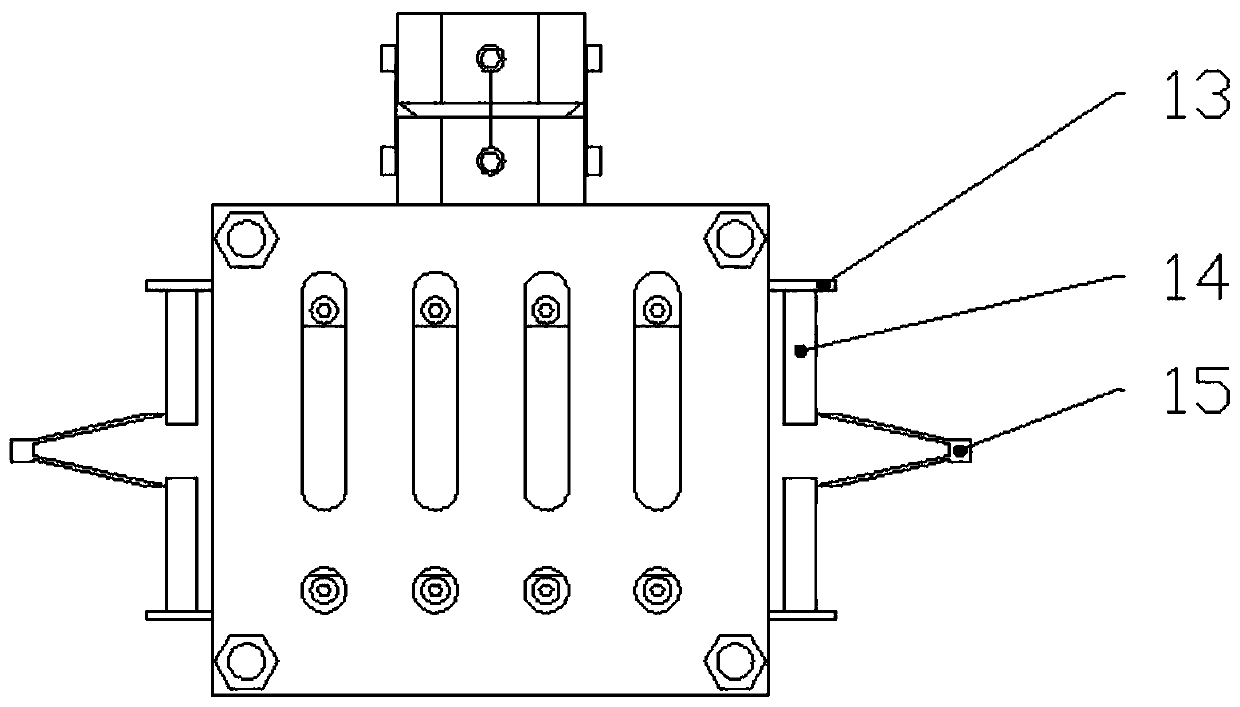

[0017] b) Install the clamping part of the test specimen. Due to the plate-like structure of the specimen, the asymmetrical installation during the lateral pressure test will easily lead to the failure of the test. When installing, put one side of the test piece (8) close to the inner wall of the upper groove (2) and the lower groove (6), clamp the test piece (8) through the gasket (7) and tighten the bolt (3), and install the left and right stoppers. Plate (9,4), because upper groove (2) can slide up and down duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com