A Method for Measuring the Tensile Mechanical Properties of Rock Rapidly

A fast and mechanical technology, applied in the field of rock tensile test, can solve the problems of long curing time, easy debonding, complicated operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

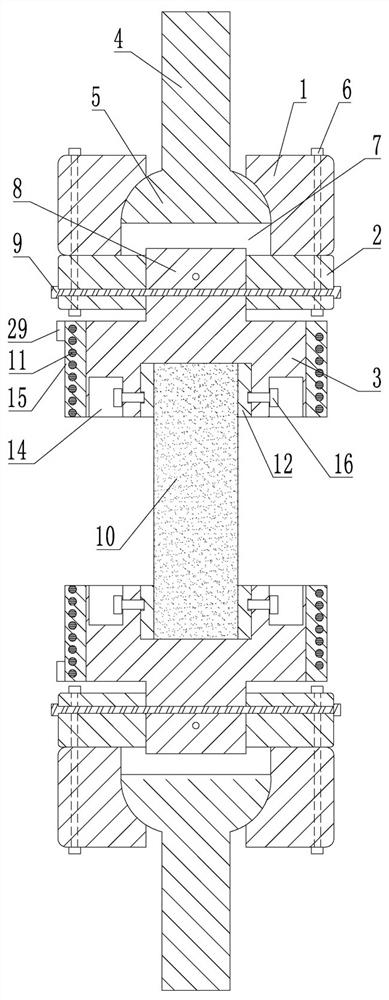

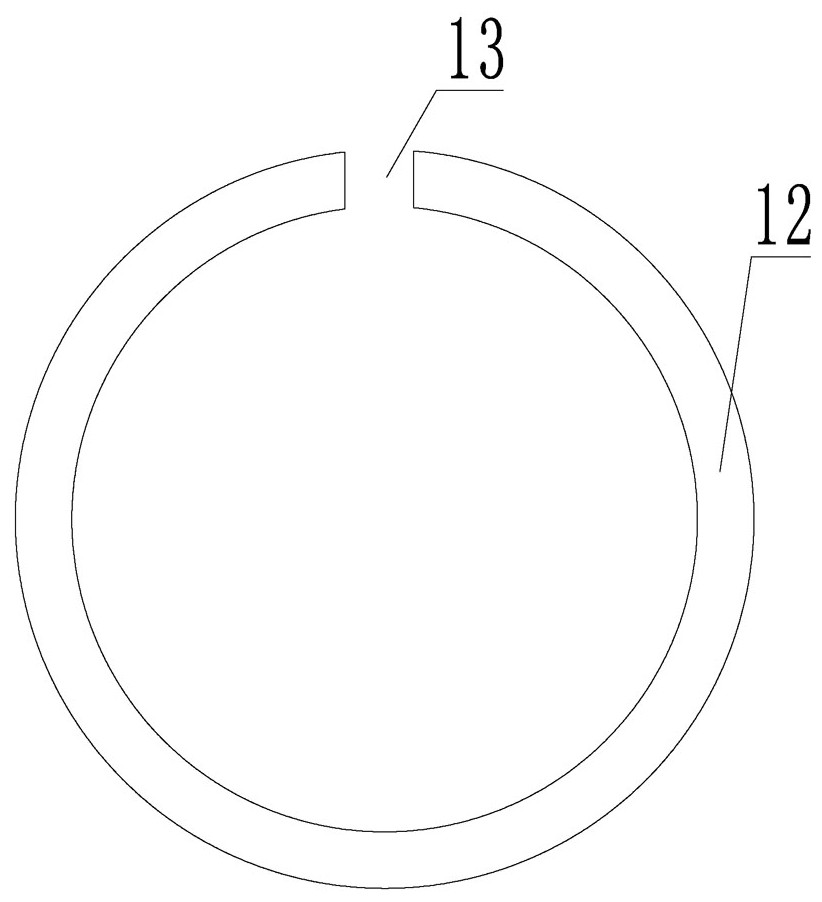

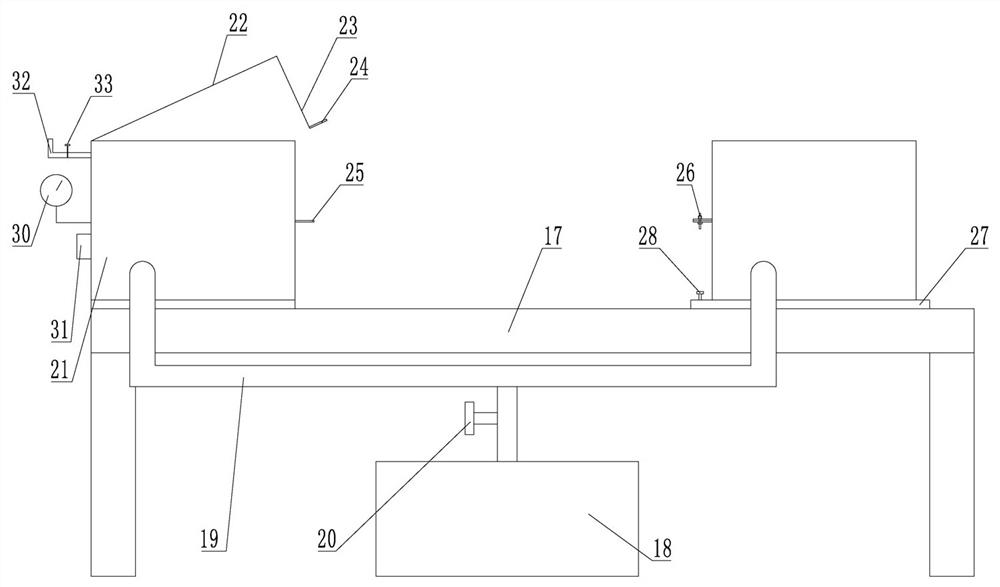

[0032] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-Figure 6 As shown, the method for quickly measuring the tensile mechanical properties of rocks includes the following steps,

[0034] (1), making a cylindrical rock sample 10;

[0035] (2) Use super glue to bond the two ends of the rock sample 10 to the clamping sleeve 3 in the clamping assembly, and use a rapid condensation device to bond the two ends of the rock sample 10 to the clamping sleeve 3 . The glue cools and solidifies quickly;

[0036] (3) After the two ends of the rock sample 10 and the clamping sleeve 3 are firmly bonded, they are taken out from the rapid condensation device, and the clamping sleeve 3 at both ends of the rock sample 10 is assembled with the rest of the clamping assembly. Then the clamping assemblies at the two ends of the rock sample 10 are fixedly installed on the tensile testing machine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com