Current collector for lithium ion battery, and lithium ion battery

A technology of lithium ion battery and current collector, applied in the field of lithium ion battery, can solve the problems of poor adhesion between current collector and active material, high application cost of lithium battery, poor conductivity of active material, etc., and achieves less use. Quantity, strong mechanical properties, and the effect of increasing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

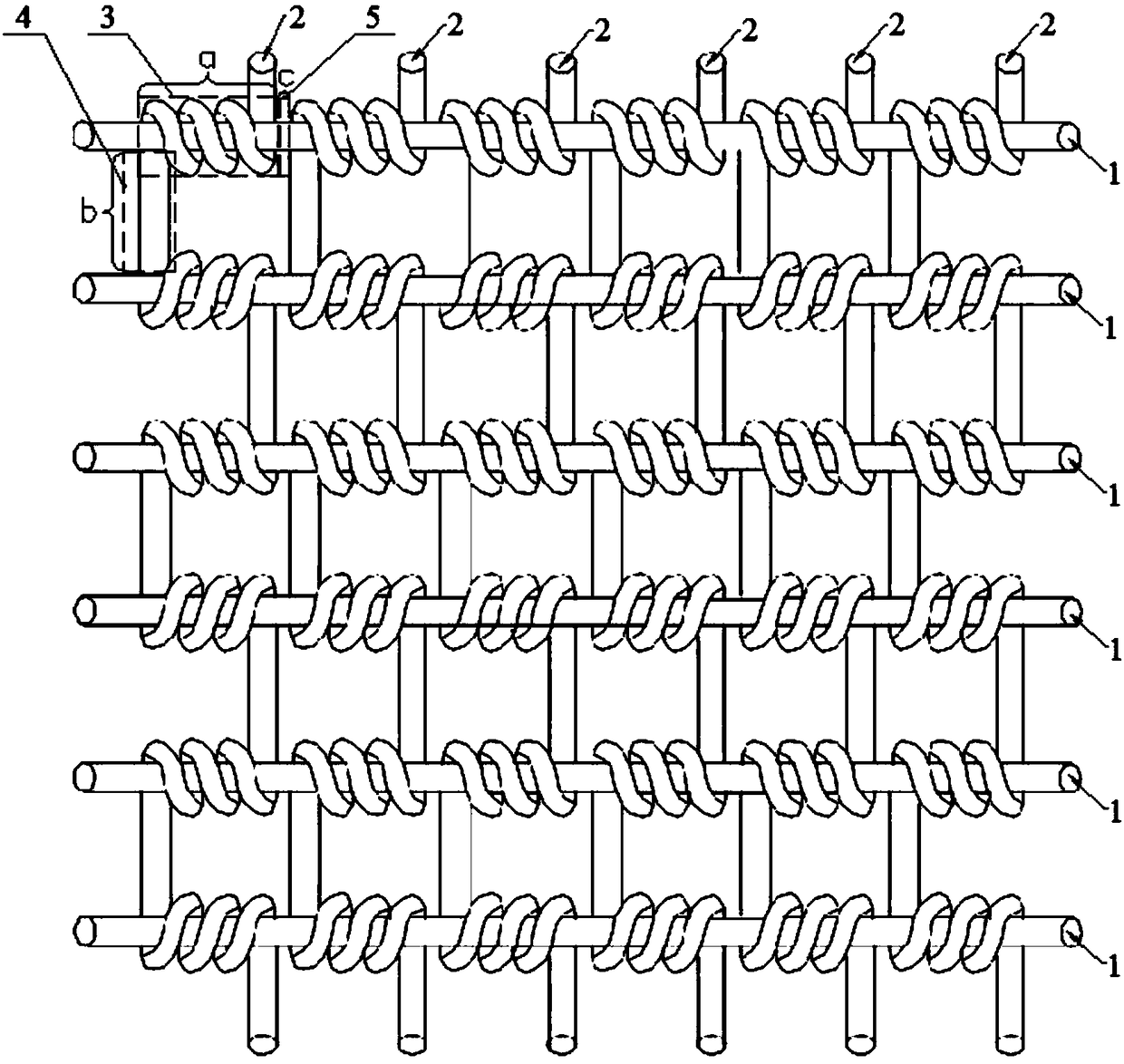

Method used

Image

Examples

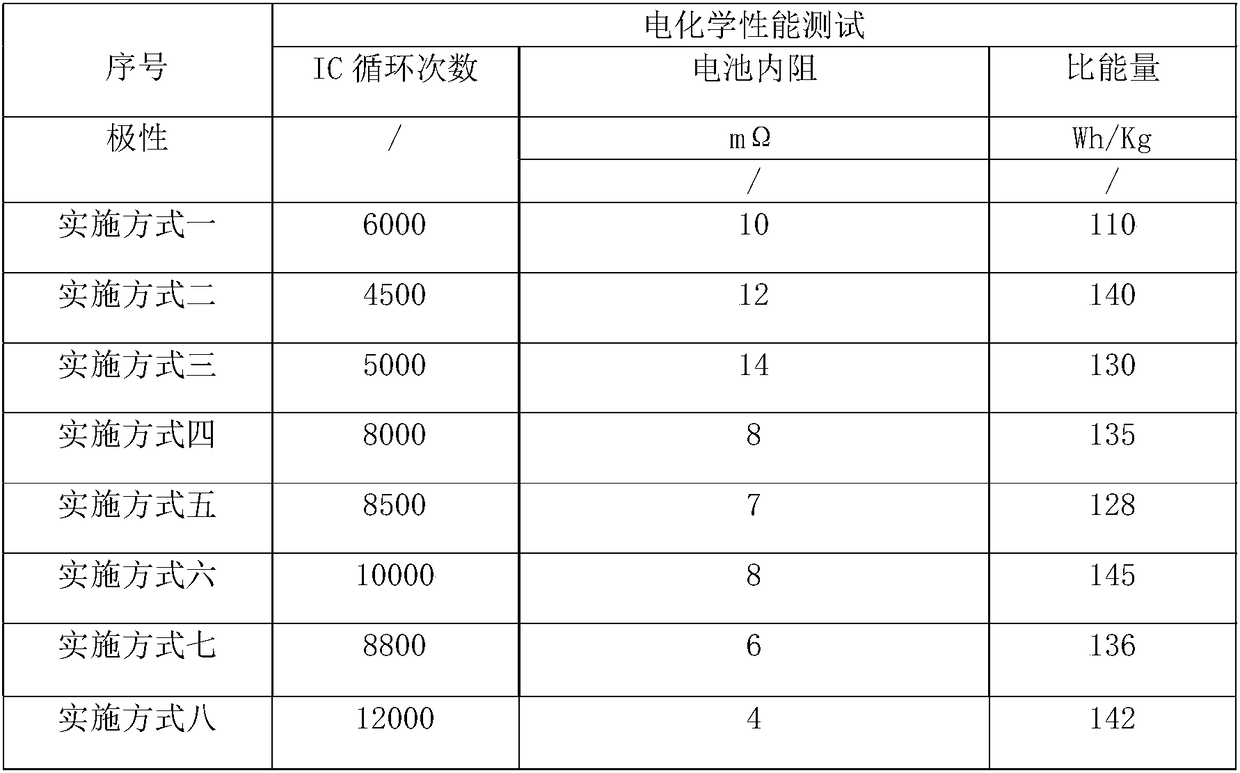

Embodiment approach 1

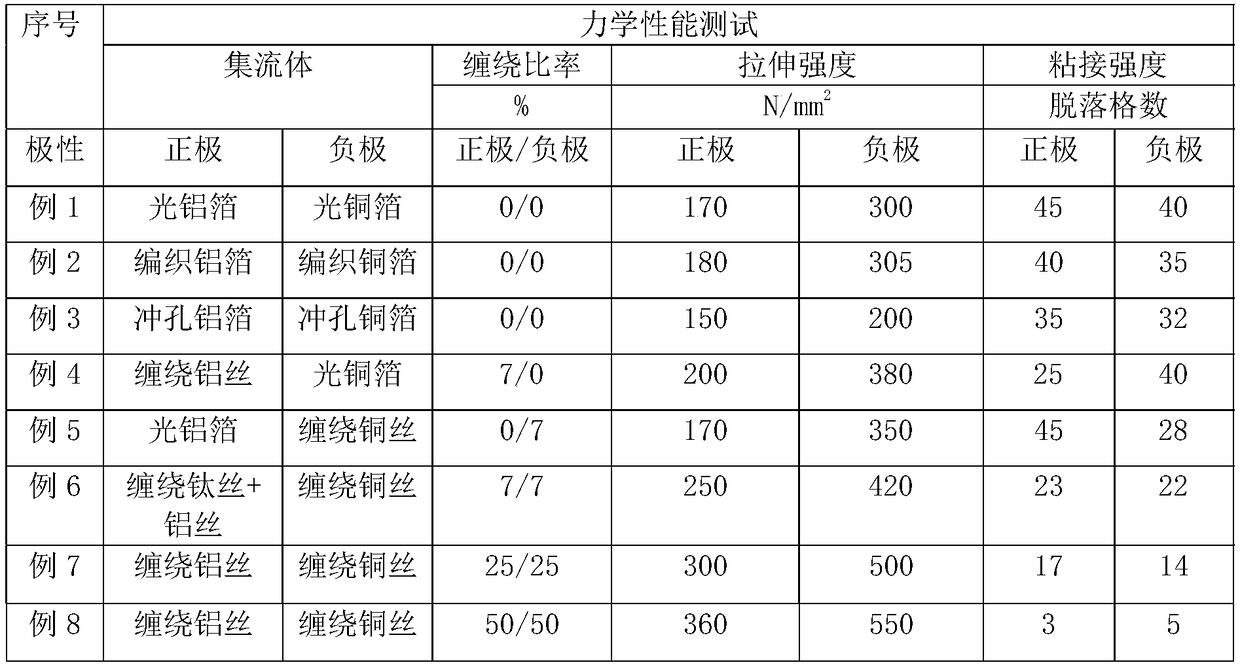

[0031] Embodiment 1 (existing light aluminum foil + light copper foil)

[0032] Negative electrode ingredients: configure graphite, binder, and deionized water as the negative electrode slurry according to the ratio of 97:3:120. After stirring at high speed for 20 hours, use a coating machine to coat the slurry on the bare copper foil with a thickness of 0.03mm. The surface coating, the thickness of the pole piece is 1.5mm after coating and drying, and the thickness of the pole piece obtained by rolling the pole piece after drying is about 0.3mm, and the light foil negative pole piece is obtained;

[0033] Positive electrode ingredients: configure lithium iron phosphate, conductive agent, PVDF binder, and NMP (N-methyl-2-pyrrolidone) as positive electrode slurry according to the ratio of 92:2:6:100. After stirring at high speed for 16 hours, use coating The machine evenly coats the positive electrode slurry on the light aluminum foil with a thickness of 0.05mm, double-sided co...

Embodiment approach 2

[0034] Embodiment 2 (existing woven aluminum foil + woven copper foil)

[0035] Select aluminum wire with a diameter of 0.03mm and copper wire with a diameter of 0.01mm to grow into a braided mesh current collector with a diameter of 10,000mm and a width of 150mm. The mesh is square, and the side length of the aluminum mesh is L 1 =0.15mm, copper mesh side length L 2 = 0.03. Mesh battery pole pieces with the same specifications are prepared according to the first coating method.

[0036] A 18650 circular battery is made by using the above-mentioned pole piece, separator, electrolyte, etc.

Embodiment approach 3

[0037] Embodiment 3 (existing perforated aluminum foil + perforated copper foil)

[0038] Select an aluminum foil with a thickness of 0.03mm and a copper foil with a thickness of 0.01mm, and use a punching method to uniformly punch holes in rows on the foil. The holes are round. The diameter of the aluminum foil hole is 0.03mm, and the diameter of the copper foil hole is 0.01mm. The perforated area accounts for 30% of the total foil area, and a perforated current collector with a length of 10,000 mm and a width of 150 mm is prepared. Pole pieces with the same specifications are prepared according to the first coating method.

[0039] A 18650 circular battery is made by using the above-mentioned pole piece, light foil negative pole piece, separator, electrolyte, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com