Square-wave structure optical illuminating realization method based on polarization

A technology of structured light illumination and realization method, which is applied in the direction of material analysis, measuring device, instrument, etc. by optical means, can solve the problem of low detection efficiency, shorten imaging time, realize sinusoidal structured light illumination, and improve defect detection efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

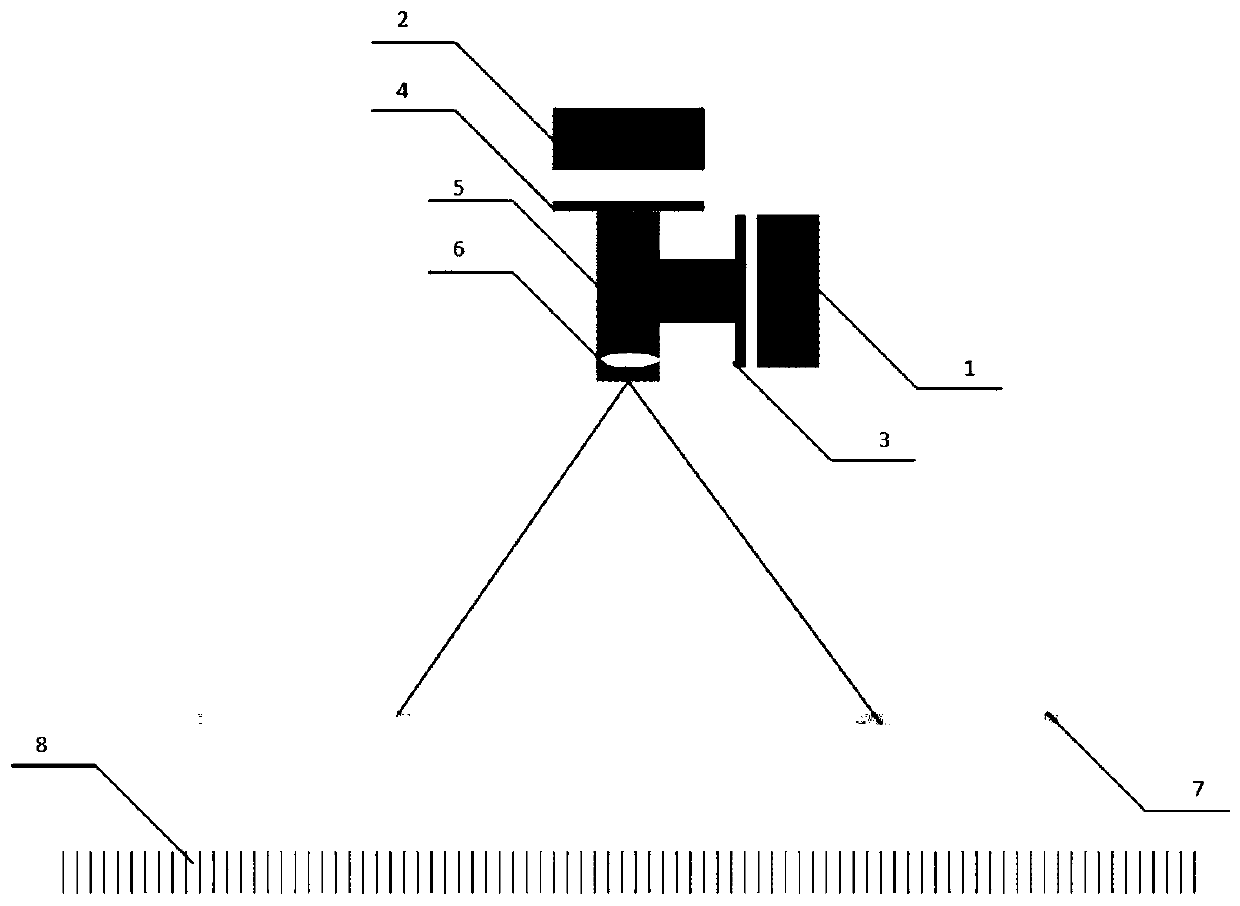

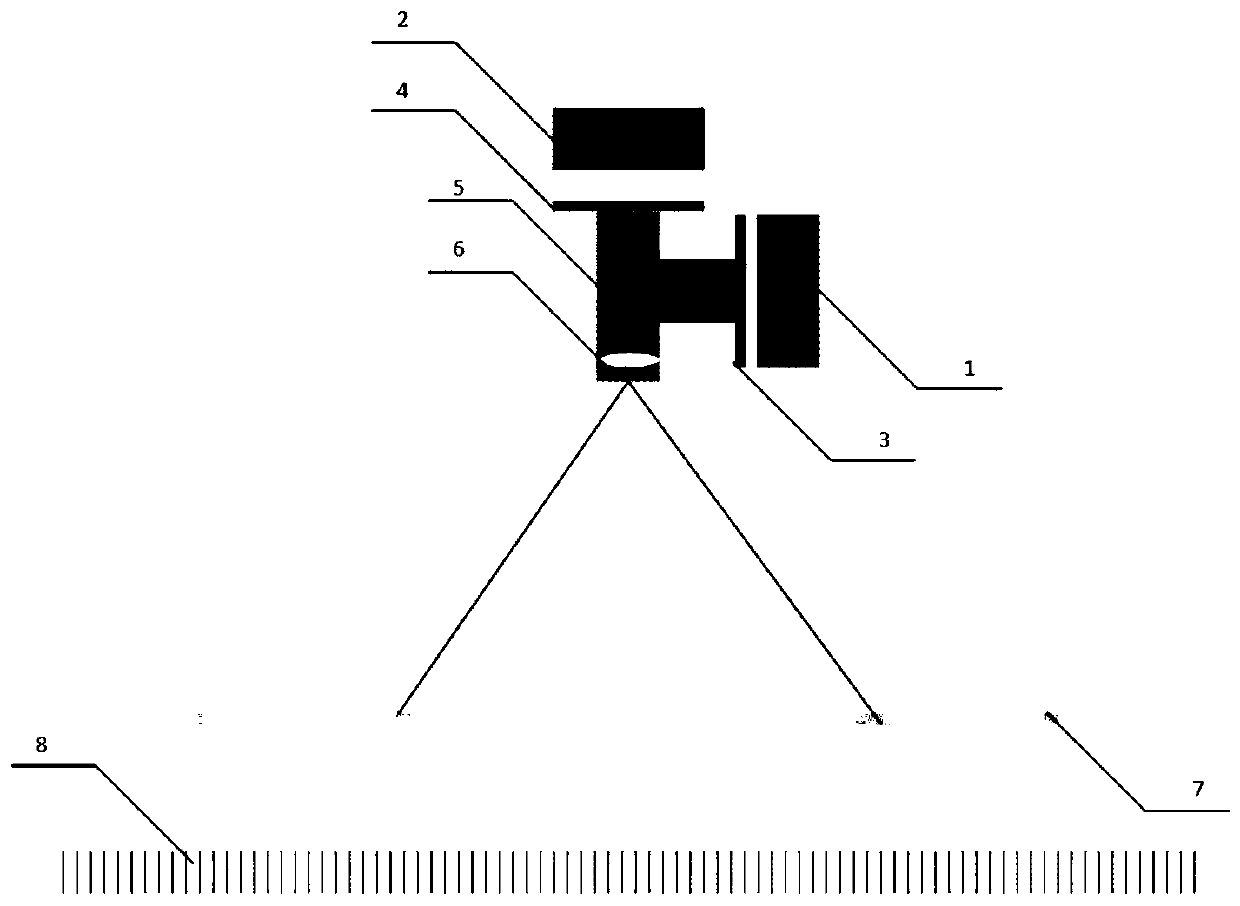

[0016] Such as figure 1 Shown, the present invention comprises the following steps:

[0017] S1. The liquid crystal display 8 is arranged at a certain distance d below the glass sample 7 to be inspected. At this time, the liquid crystal display 8 is in a defocused state, and the light intensity on the liquid crystal display 8 is distributed in black and white square wave stripes;

[0018] The liquid crystal display 8 realizes the adjustment of the display gray scale by controlling the phase difference between two orthogonal polarization directions: when the liquid crystal display 8 displays the minimum gray value, the outgoing light of the liquid crystal display 8 is perpendicular to the polarization direction of the polarizing film on its surface; When the liquid crystal display 8 displayed the maximum gray value, the outgoing light of the liquid crystal display 8 was parallel to the polarization direction of the polarizing film on its surface;

[0019] S2. A first camera mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com