Multichannel constant-force intelligent controller based on DSP (Digital Signal Processor)

An intelligent controller and controller technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of poor anti-interference ability, the system does not have fast real-time control, low transmission rate, etc., to achieve measurement accuracy and transmission. The effect of speed improvement, convenient on-site debugging and analysis, and convenient simultaneous control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

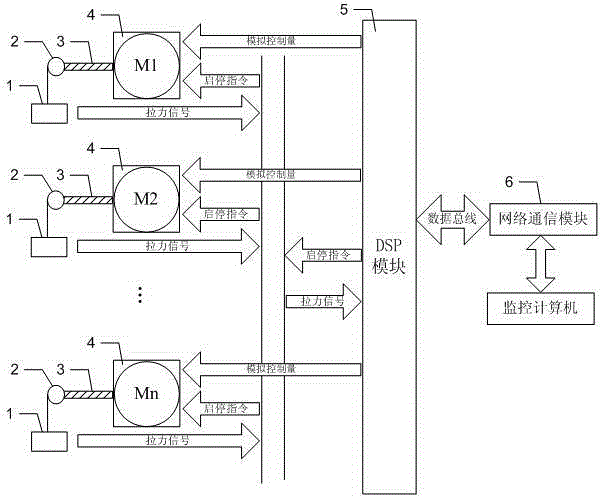

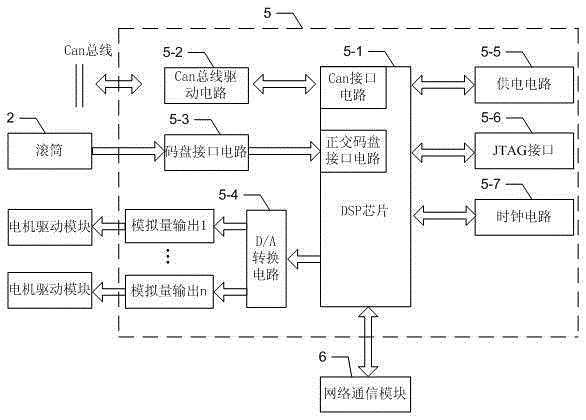

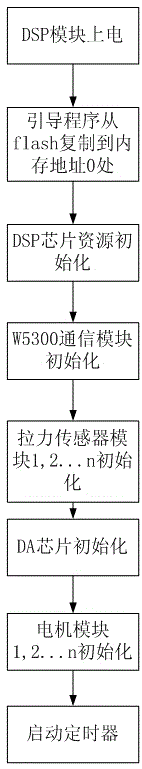

[0017] Specific embodiment one: the following combination Figure 1 to Figure 4 Describe this embodiment, the multi-channel constant force intelligent controller based on DSP described in this embodiment, the controller controls multiple constant force devices at the same time, each constant force device is provided with a motor 4, and the output shaft 3 of the motor 4 is connected Drum 2, the sling hanging the load goes around the drum 2, and the sling is provided with a tension sensor 1 for monitoring the tension signal of the load;

[0018] The DSP-based multi-channel Hengli intelligent controller includes a DSP module 5 and a network communication module 6;

[0019] The DSP module 5 issues start and stop commands to the n motors 4 of the multi-channel constant force device through the Can bus;

[0020] The tension signal monitored by the tension sensor 1 of each constant force device is sent to the DSP module 5 through the Can bus, and the DSP module 5 outputs the analog ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com