Centrifugal pump having a radial impeller

A centrifugal pump and impeller technology, applied in the direction of pumps, components of pumping devices for elastic fluids, pump components, etc., can solve the problems of design cost, easy failure, etc., and achieve the effect of improving efficiency and reliable operation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

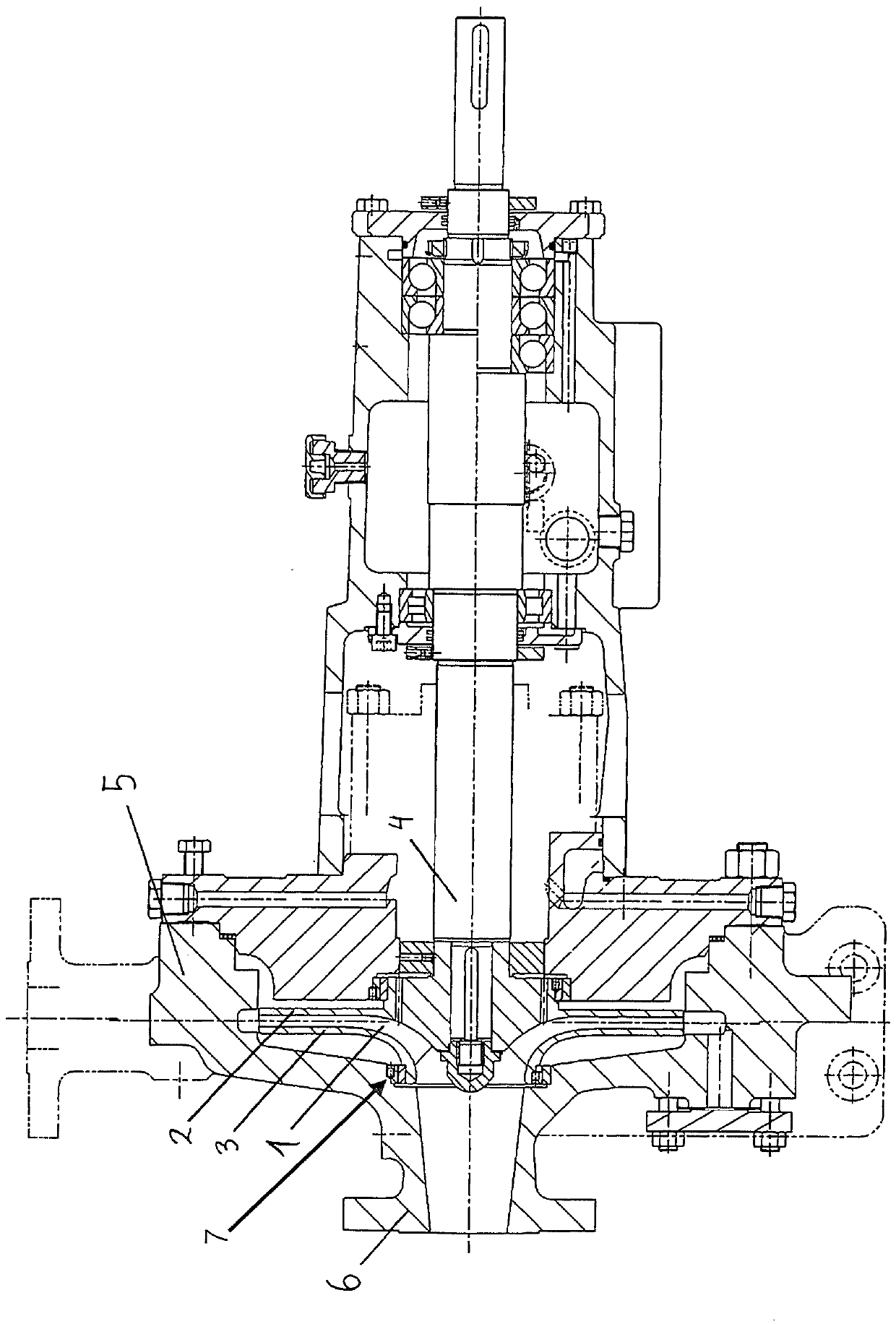

[0029] figure 1 A centrifugal pump with impeller 1 is shown. The impeller 1 is designed as a closed radial impeller and has a carrier disk 2 and a cover disk 3 . Blades are arranged on the carrier plate 2 . A channel for transporting the medium is formed between the carrier tray 2 and the cover tray 3 . The impeller 1 is driven by the shaft 4 . The impeller 1 is surrounded by a housing 5 which can be constructed in multiple parts. The housing 5 has a suction nozzle 6 . The centrifugal pump has a gap ring seal 7 . The gap ring seal 7 limits the gap volume flow, which flows back from the pressure region of the centrifugal pump into the suction region. The impeller 1 is designed as a radial impeller. The fluid flows to the impeller 1 in the axial direction and is then deflected by 90º and discharged from the impeller 1 in the radial direction.

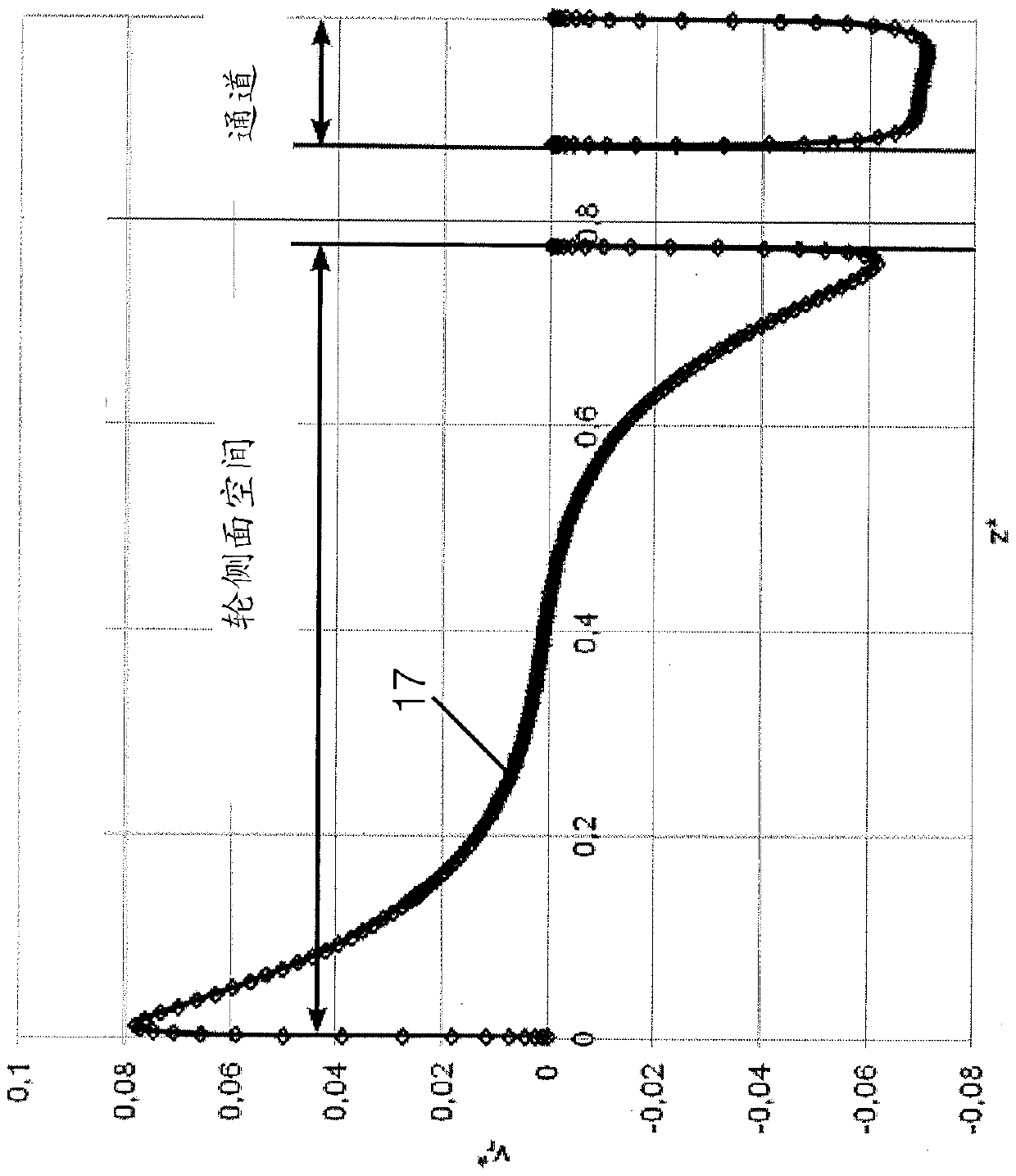

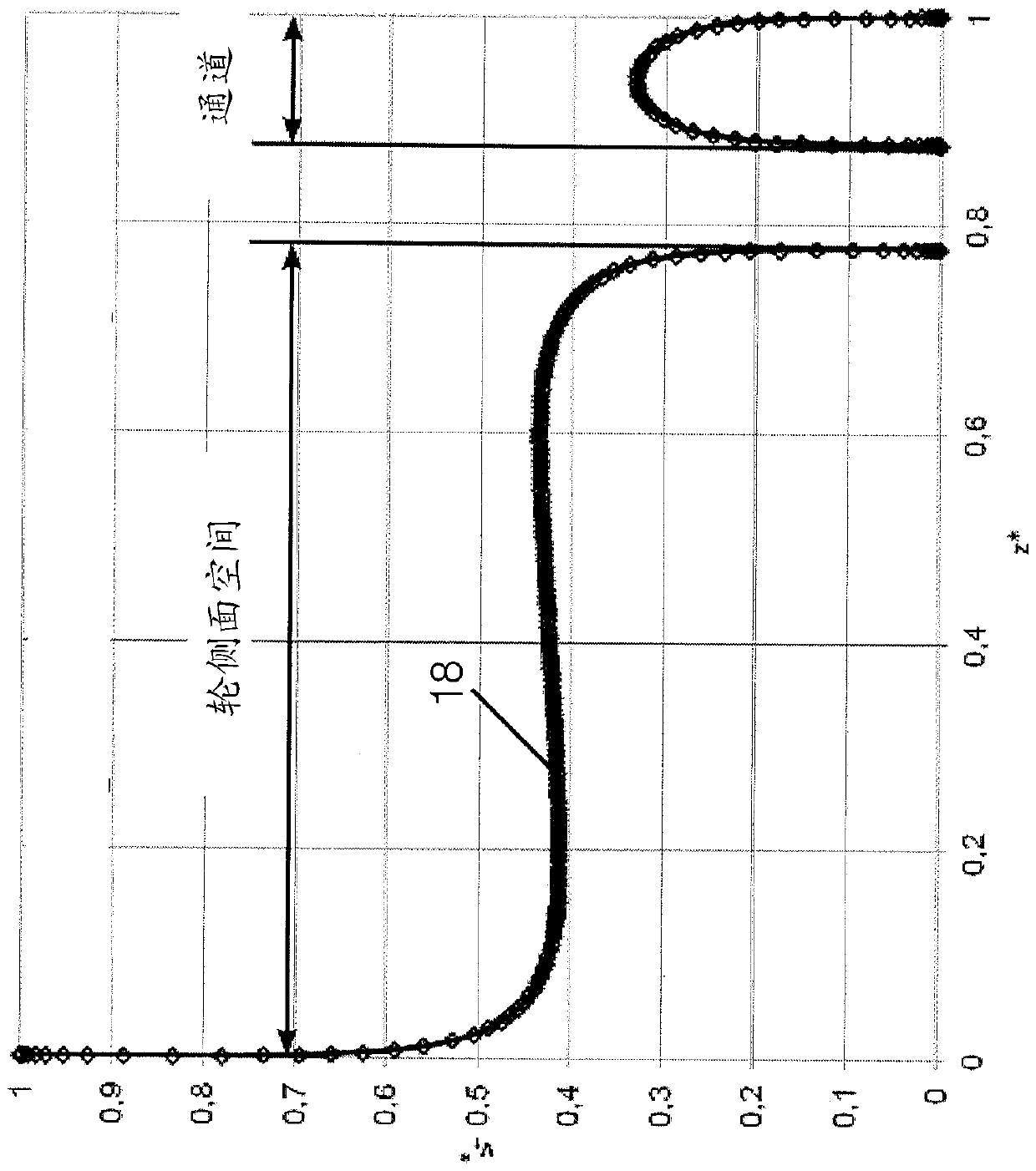

[0030] figure 2 A schematic view of the front wheel-side space 8 formed between the cover plate 3 and the housing part 9 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com