Sorting structure of quartz sand sorting device

A sorting device and quartz sand technology, applied in the field of quartz sand sorting, can solve the problems of low efficiency and long production process of quartz sand, and achieve the effect of improving efficiency and shortening the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following is further described in detail by specific embodiments:

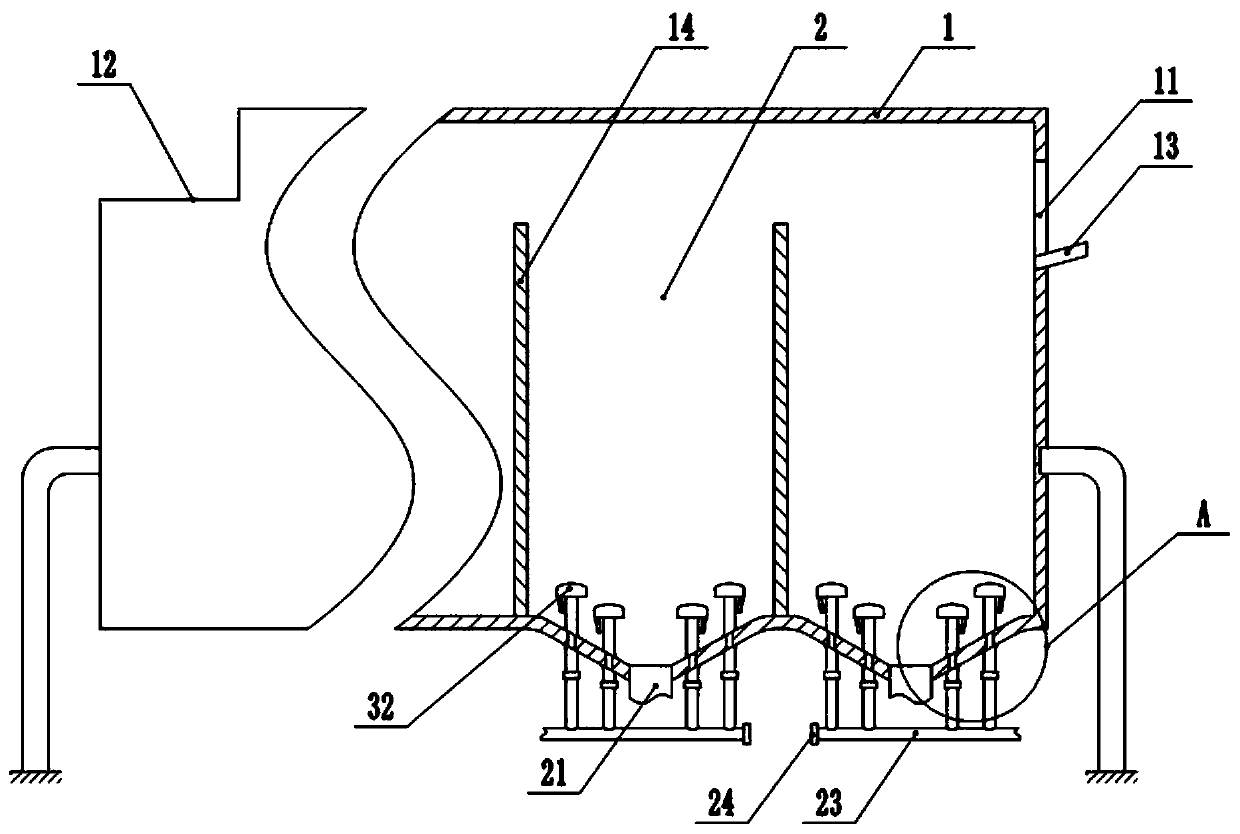

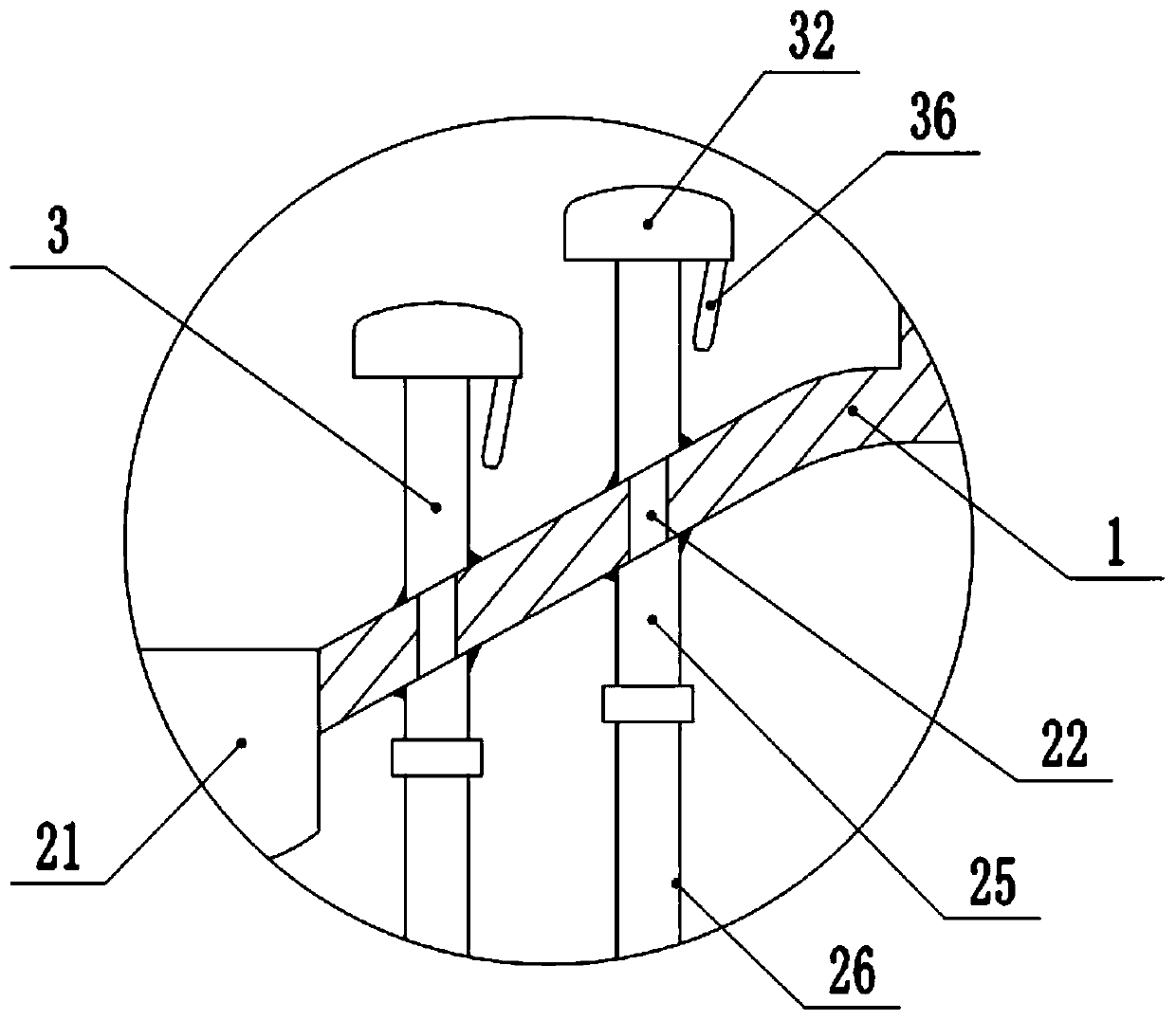

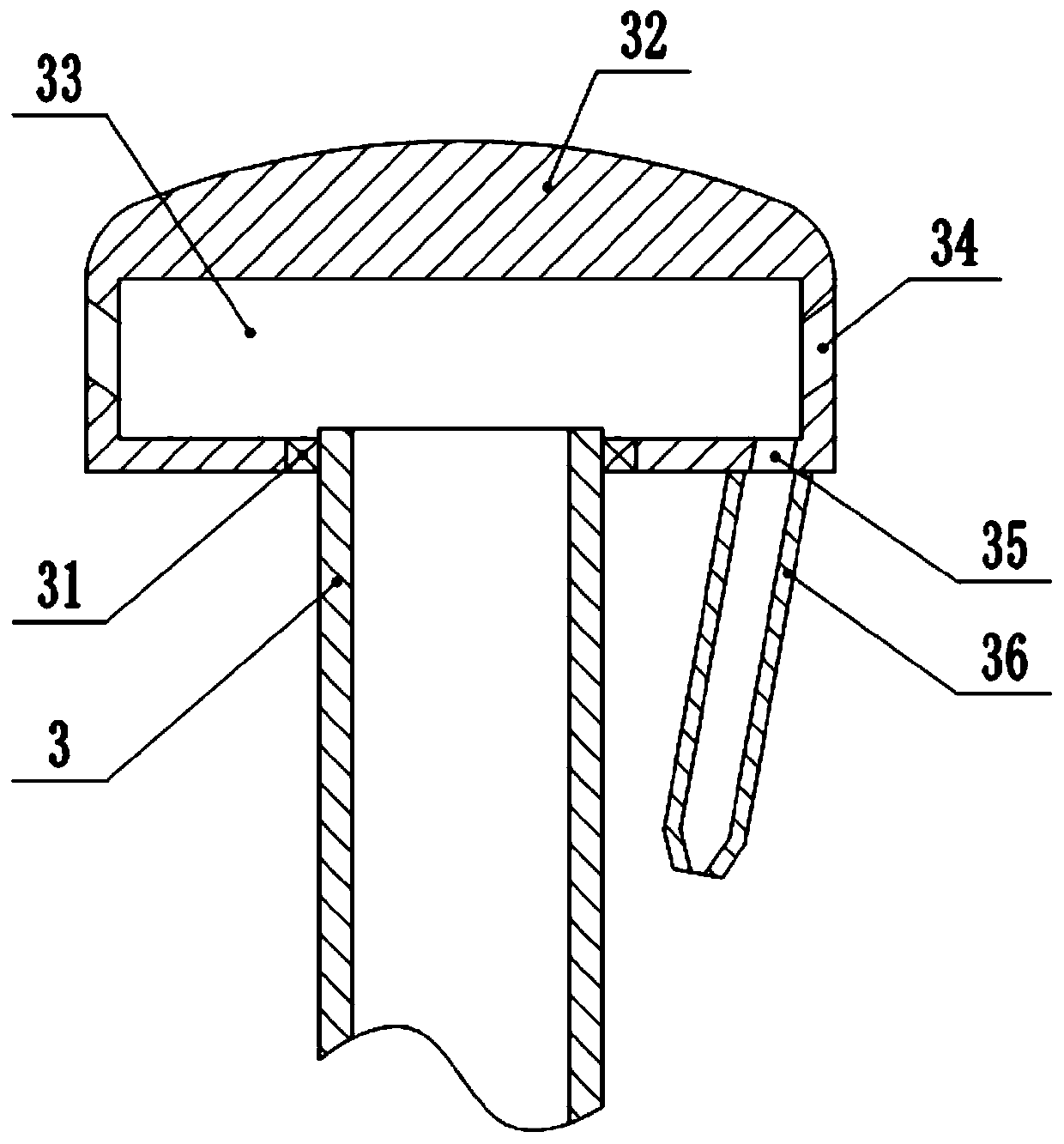

[0032] The reference signs in the drawings include: sorting box 1, sand inlet 11, sand outlet 12, material guide plate 13, partition 14, sorting cavity 2, sand discharge pipe 21, water injection port 22, multi-pass Pipe 23 , end cover 24 , connecting pipe 25 , metal pipe 3 , bearing 31 , water spray disc 32 , water cavity 33 , water spray hole 34 , sand cleaning hole 35 , and sand cleaning pipe 36 .

[0033] The example is basically as attached figure 1 shown:

[0034] A sorting structure of a quartz sand sorting device includes a frame and a sorting box 1 fixed on the frame. One end of the sorting box 1 is provided with a sand inlet 11, and the other end is provided with a sand outlet 12. An inclined guide plate 13 is fixed at the sand port 11. The high end of the guide plate 13 is located outside the sorting box 1. In addition, the sand inlet 11 and the sand outlet 12 are both located at the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com