Intelligent auxiliary transporting system for underground coal mine diesel and electric independently-driven rubber-tired vehicle

An independent drive and auxiliary transportation technology, applied in electric vehicles, underground transportation, transportation and packaging, etc., can solve the problems affecting the health of coal mine employees, personal health injuries, and high vehicle exhaust emissions, and achieve solutions to reduce braking efficiency, intelligent The effect of advanced management and reduction of head noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described in more detail below in conjunction with specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

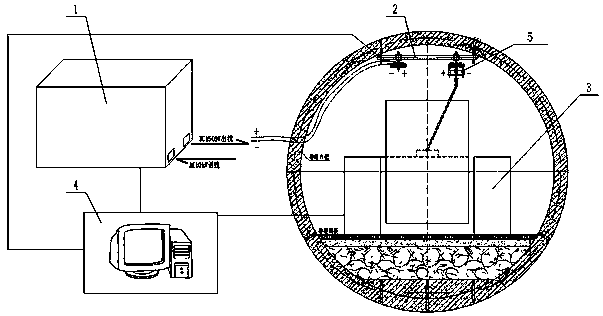

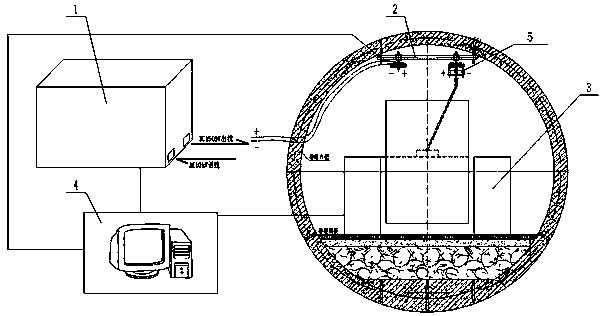

[0017] refer to figure 1 , figure 1 It is a structural schematic diagram of an intelligent auxiliary transportation system for rubber-tyred vehicles independently driven by diesel and electric vehicles in coal mines provided by the present invention.

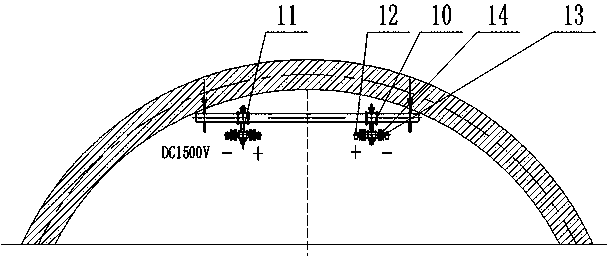

[0018] The system includes: power supply system 1, catenary system 2, dual-power vehicle 3, and intelligent information dispatching system 4; among them, catenary system 2 is erected on the top of the main air inlet lane of the coal mine, and adopts the layout of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com