PC/PMMA material for suitcase shell and preparation method thereof

A technology for casings and bags, which is applied in the field of PC/PMMA material and its preparation for casings of bags, and can solve the problems of poor compatibility between PC and PMMA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

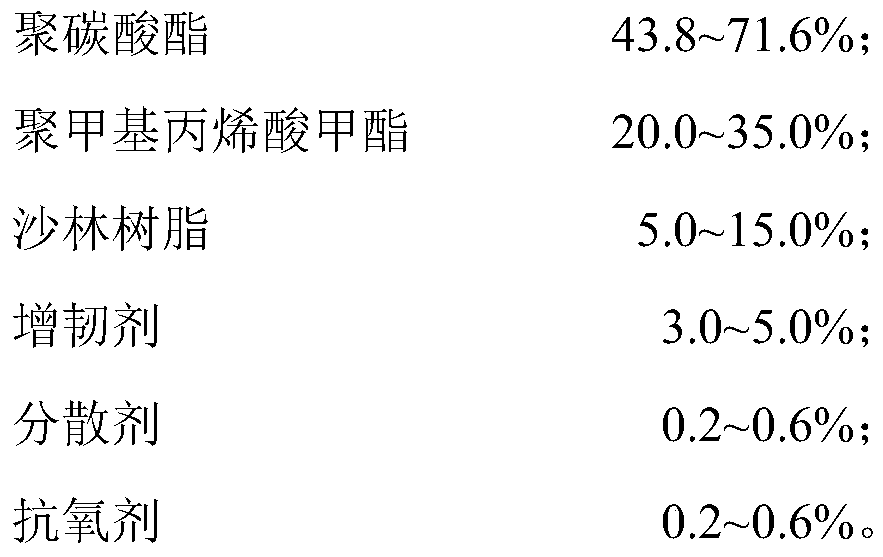

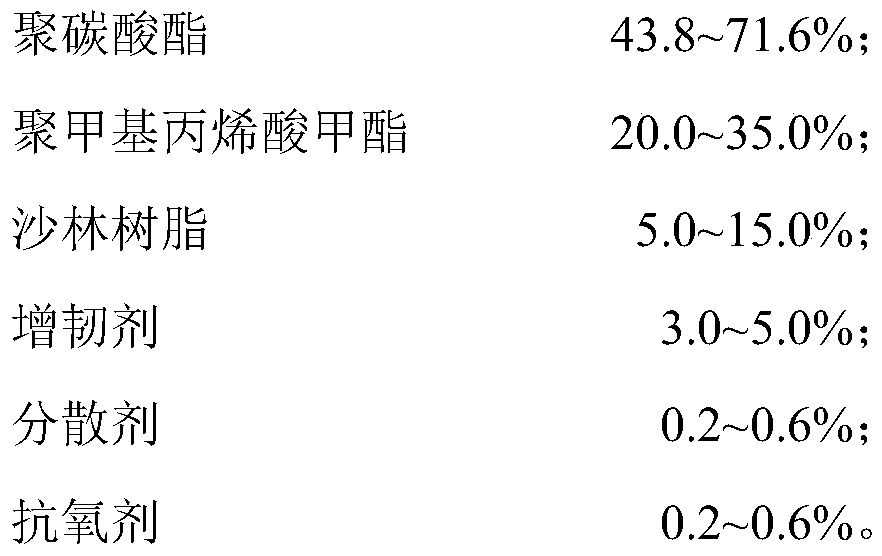

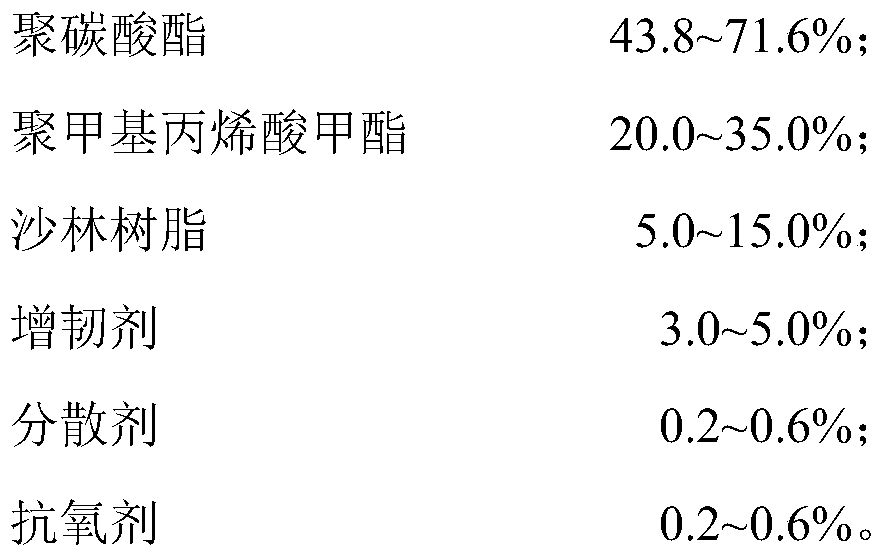

Method used

Image

Examples

Embodiment 1~5

[0032] Raw material: see table 1

[0033]Preparation method: Put the raw materials into the mixing pot and mix evenly. The speed of the mixing pot is 450r / min, and the mixing time is 4min. The temperatures of each section of the twin-screw extruder are: 240°C, 245°C, 245°C, 250°C, 255°C, 260°C, 250°C, 250°C, 245°C, 245°C, the head temperature is 260°C, the screw The rotating speed is 400r / min, the vacuum degree is not less than 0.8MPa, and the PC / PMMA material used for the case shell is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com