A tempering device for heat treatment of wear-resistant parts

A technology of tempering device and wear-resistant parts is applied in the field of tempering devices for heat treatment of wear-resistant parts, which can solve the problems of heavy burden on processing personnel, small amount of processing, and inability to effectively ensure that multiple wear-resistant parts are tempered at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Attached below Figure 1-5 The present invention is further described with embodiment:

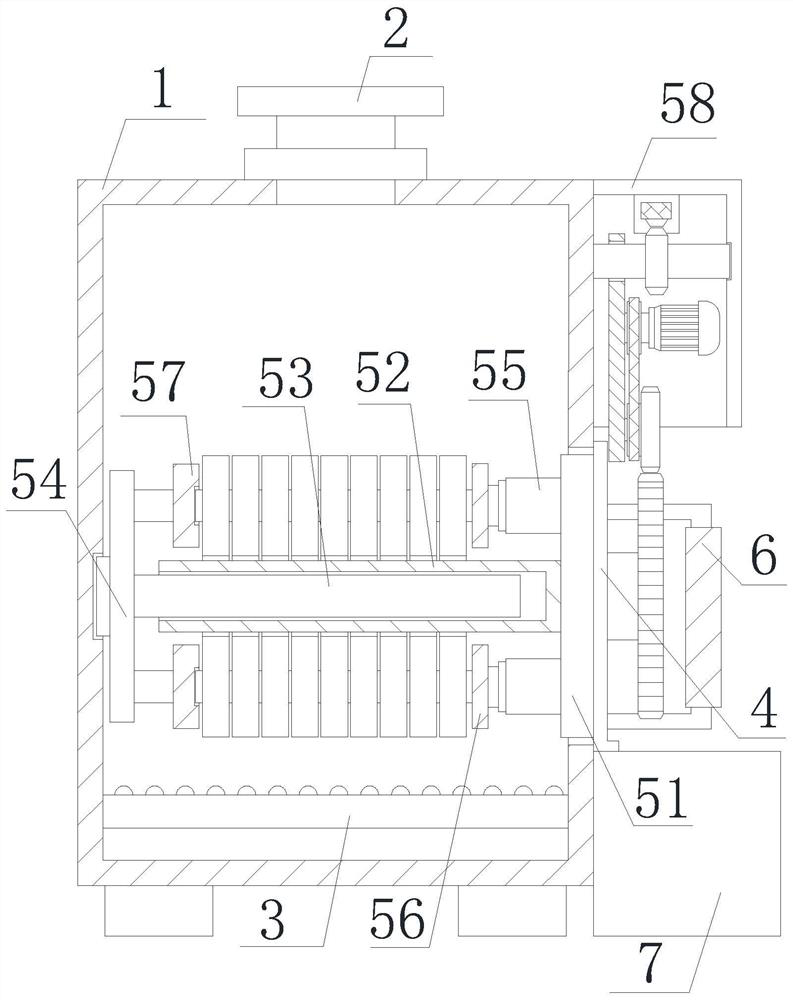

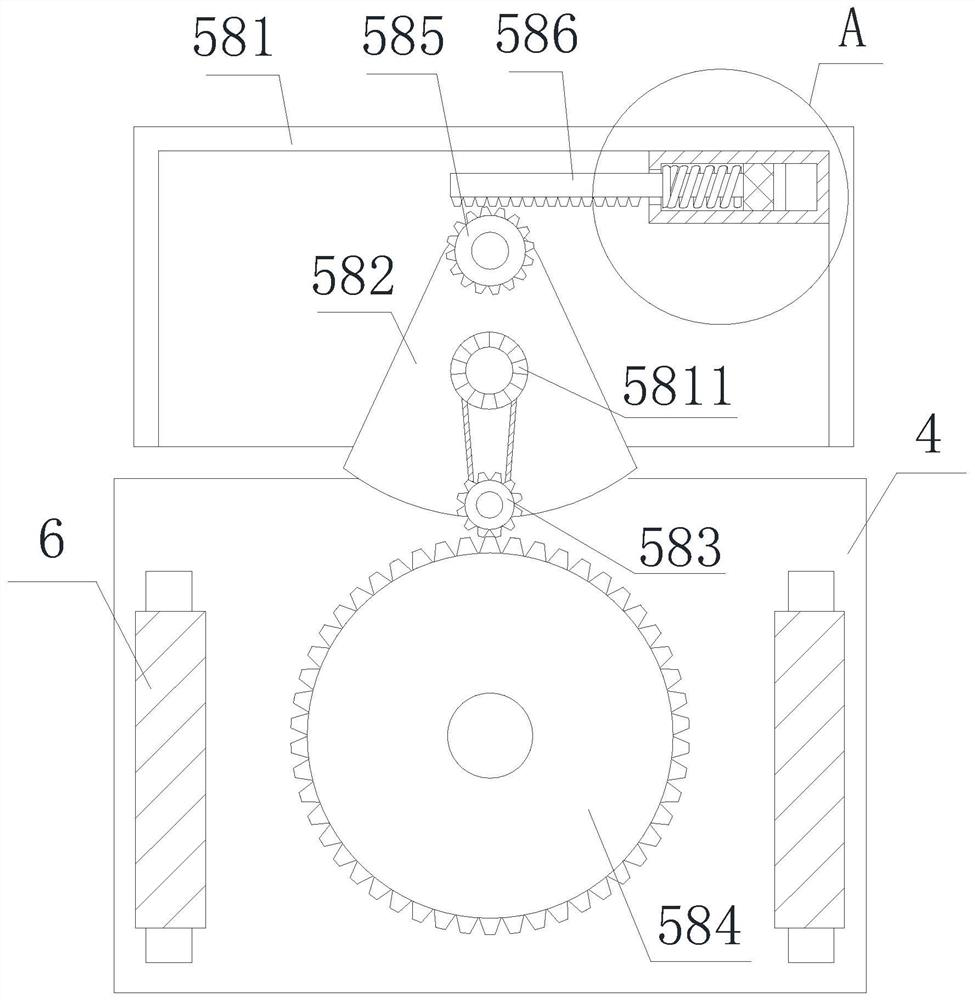

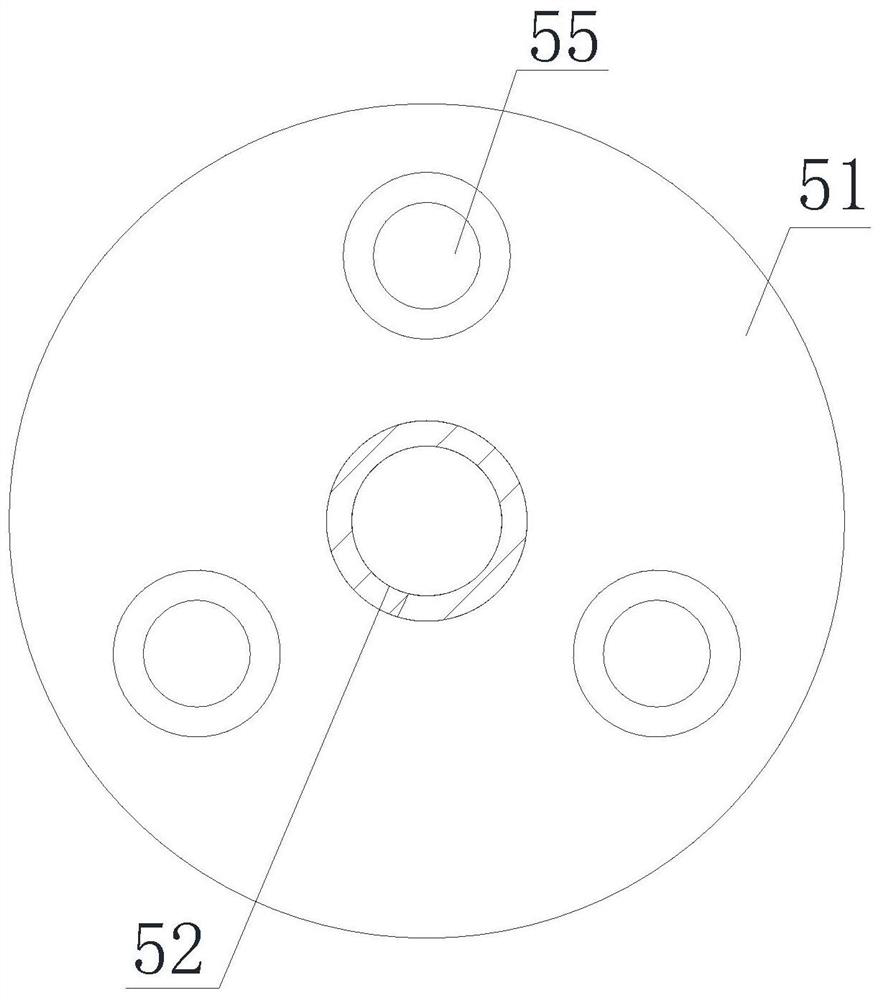

[0029] A tempering device for heat treatment of wear-resistant parts, comprising an outer box 1 of the device and a plurality of supporting feet installed at the lower end of the outer box 1 of the device, the upper end of the outer box 1 of the device is provided with an air hole 2 for connecting an external air source, injecting The inert gas prevents the oxidation of the wear-resistant parts, and the lower part of the inner cavity of the outer box 1 of the device is provided with a heating assembly 3 to heat and temper the wear-resistant parts. In this embodiment, the heating assembly 3 is a plate-type resistance wire heater. A box door 4 is installed on the side wall of the outer box 1 of the device, and the door 4 is a pull-out structure, which is convenient to put in and take out. The inner cavity of the outer box 1 of the device is provided with a uniform tempering device 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com