Vertical peanut kernel red skin-removing and tempering machine

A conditioning machine and peanut kernel technology, applied in food processing, shelling, pod removal, etc., can solve the problems of difficulty in increasing production, poor conditioning effect, low production output, etc., and achieve significant energy saving, energy saving, and occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

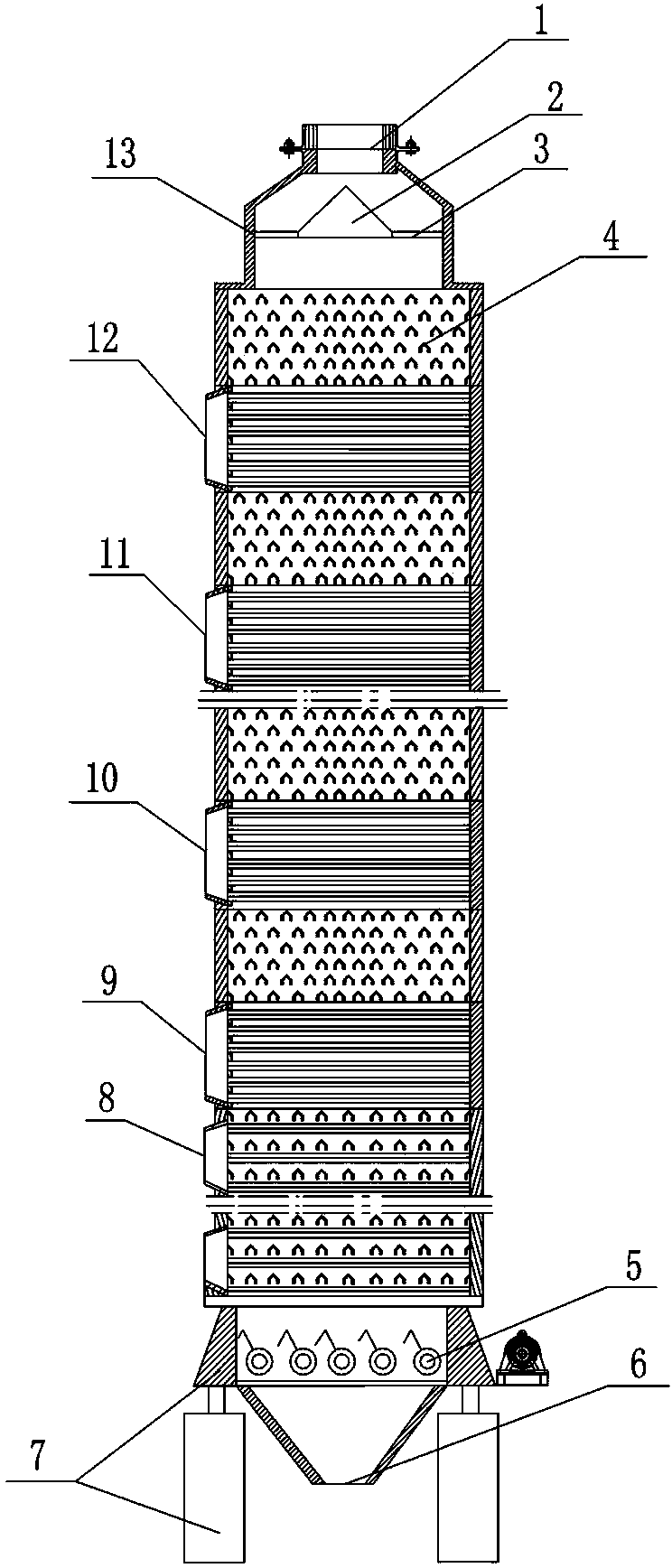

[0029]The material enters the conditioning machine through the material moving stack 23 and the material lifting frame 19. With the uniform decline of the material in the vertical peanut red coat conditioning machine, the incoming material first passes through the slow release device 2, and then enters the first stage of heating. Dryer, the first-level heating dryer uses the induced draft fan 22, and then directly passes through the first-level heating medium inlet 12 for heating. The hot air enters from the opening at one end of the angular box structure 4 of the lower box, and the other end is airtight. , the hot air is transmitted to various positions by using the lower space of the angular box structure 4, and under the action of wind pressure, the hot air overflows from the bottom of the angular box structure 4 and flows through the material gap to heat and dry the material, and the heated and dried hot air enters the upper The lower part of the angular box structure 4 of ...

Embodiment 2

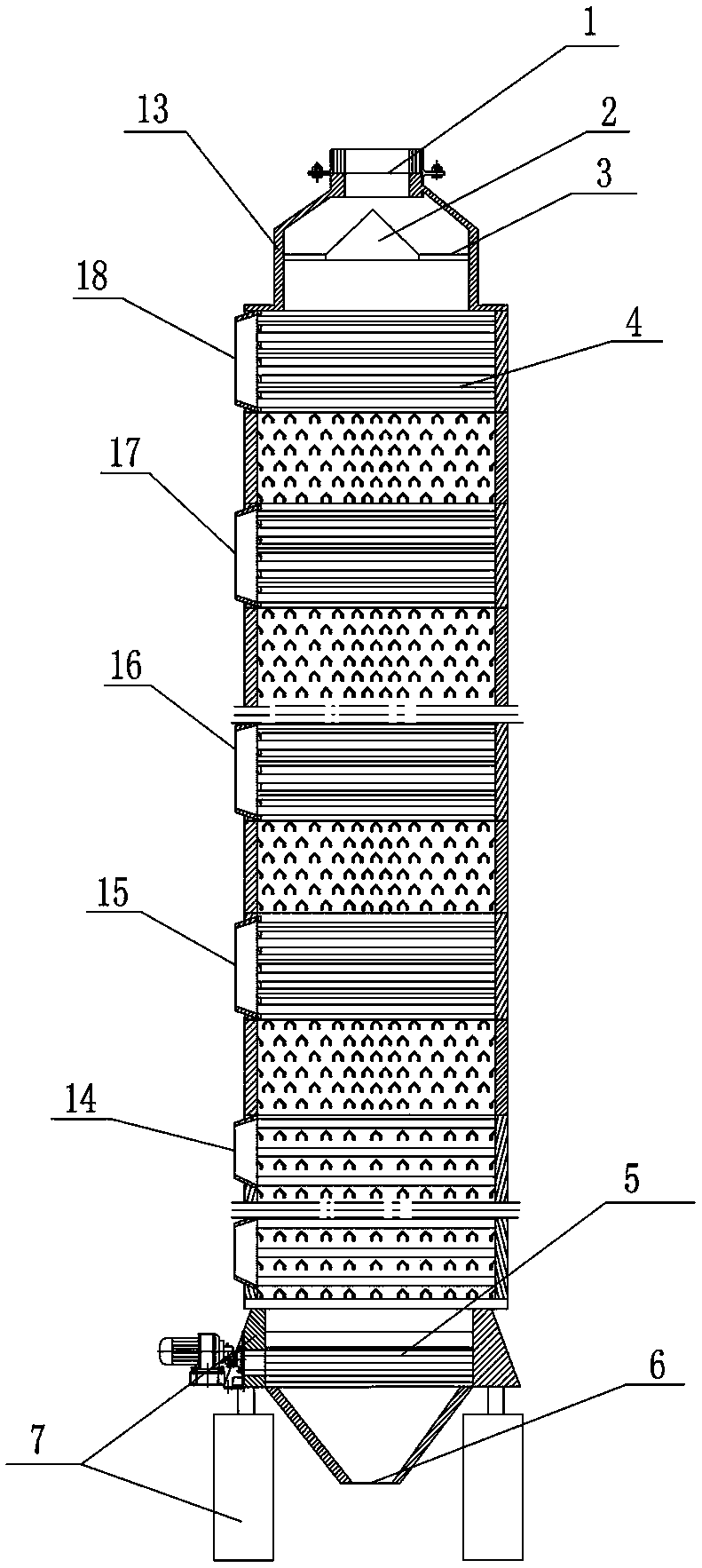

[0032] Embodiment 4: see Figure 9 , is basically the same as Example 3, and the same parts are not repeated. The difference is that the heating and drying device is an independent box, and the box is a structure with openings at both ends of the upper and lower ends. The box contains at least two rows of horizontal Vertical and staggered angular box structure.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com