Crowned tooth machining process for rail transit

A processing technology and rail transit technology, applied in metal processing equipment, metal processing machinery parts, gear teeth, etc., can solve problems such as uneven tempering of drum-shaped teeth, increase tempering range, improve tempering efficiency, and improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

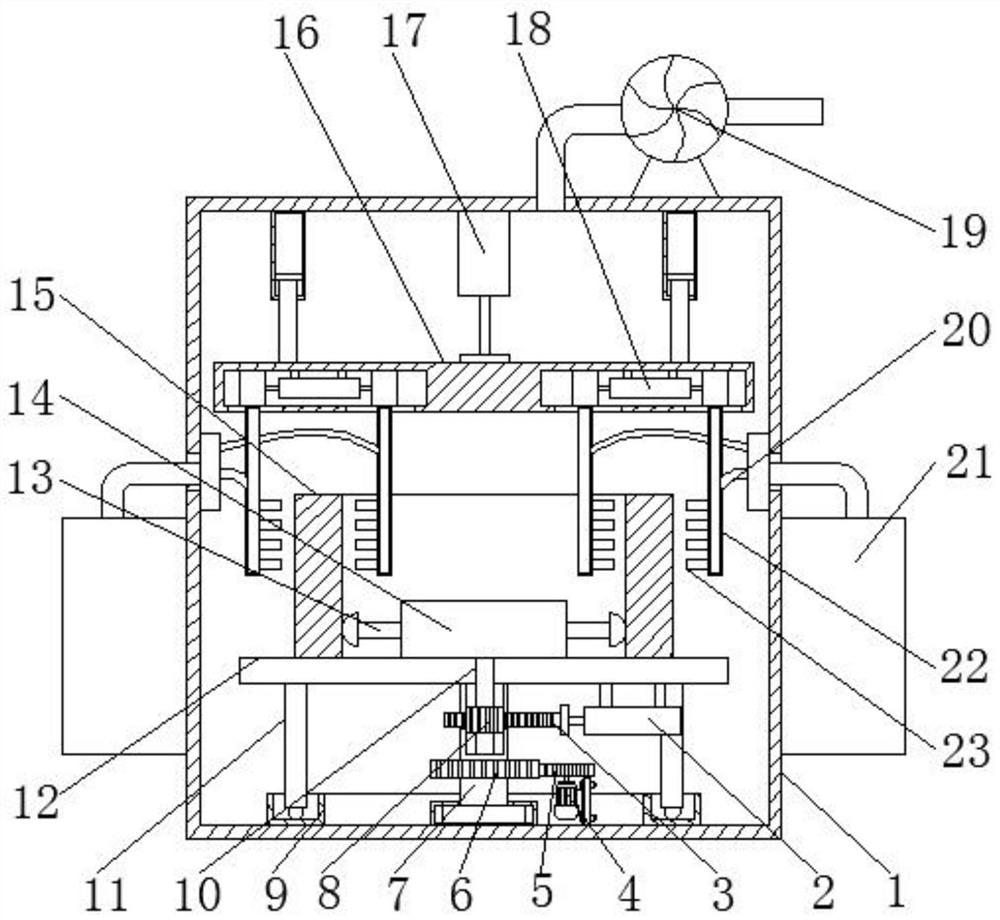

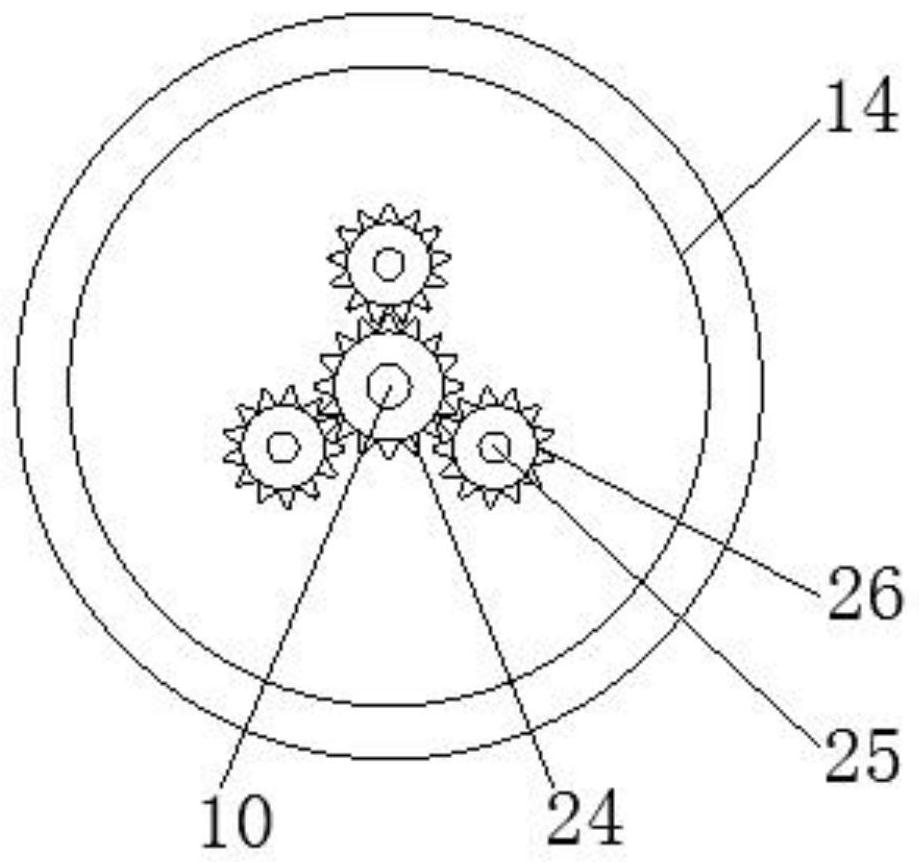

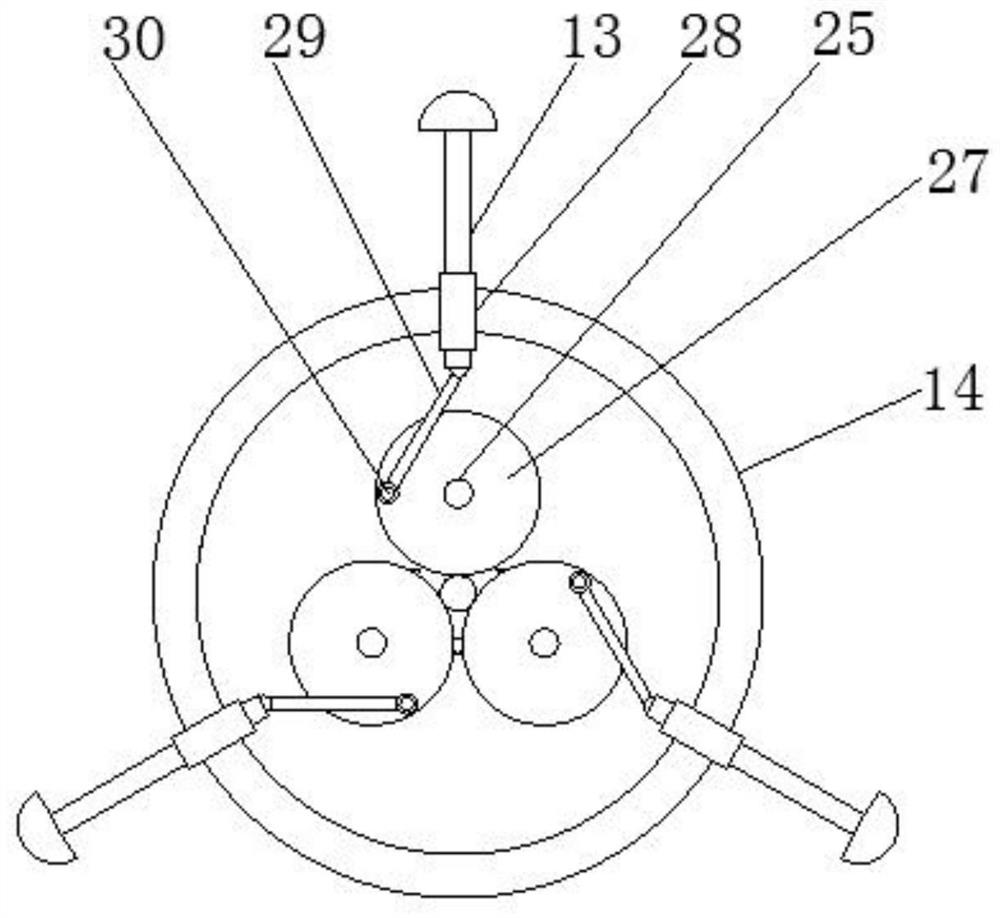

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0038] refer to Figure 1-5 , a drum-shaped tooth processing technology for rail transit, comprising the following steps:

[0039] S1: Rough machining

[0040] Select 31CrMoV9 forging blanks for rough machining, with a margin of 4-8mm;

[0041] S2: conditioning

[0042] The workpiece after rough machining is quenched and tempered, and the hardness is 32-38HRC. This hardness basis makes the workpiece not easy to deform during semi-finishing, and correspondingly avoids the possibility of deformation of the workpiece during finishing machining;

[0043] S3: semi-finishing

[0044] Semi-finishing the workpiece after quenching and tempering, the allowance is 0.4-0.8mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com