Device and method for continuously producing piezoelectric fibers

A piezoelectric fiber and fiber technology, applied in the field of continuous production of piezoelectric fibers and devices for continuous production of piezoelectric fibers, can solve the problems that the production and polarization of piezoelectric fibers cannot be carried out at the same time, and achieve light weight, convenient collection, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

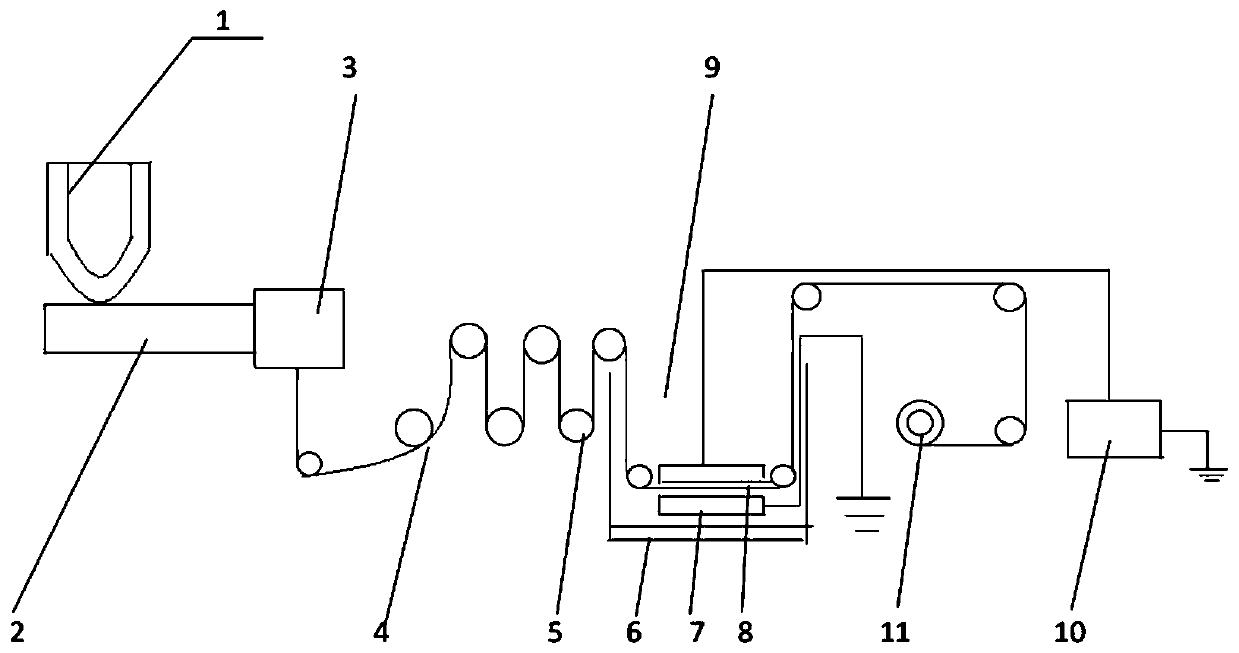

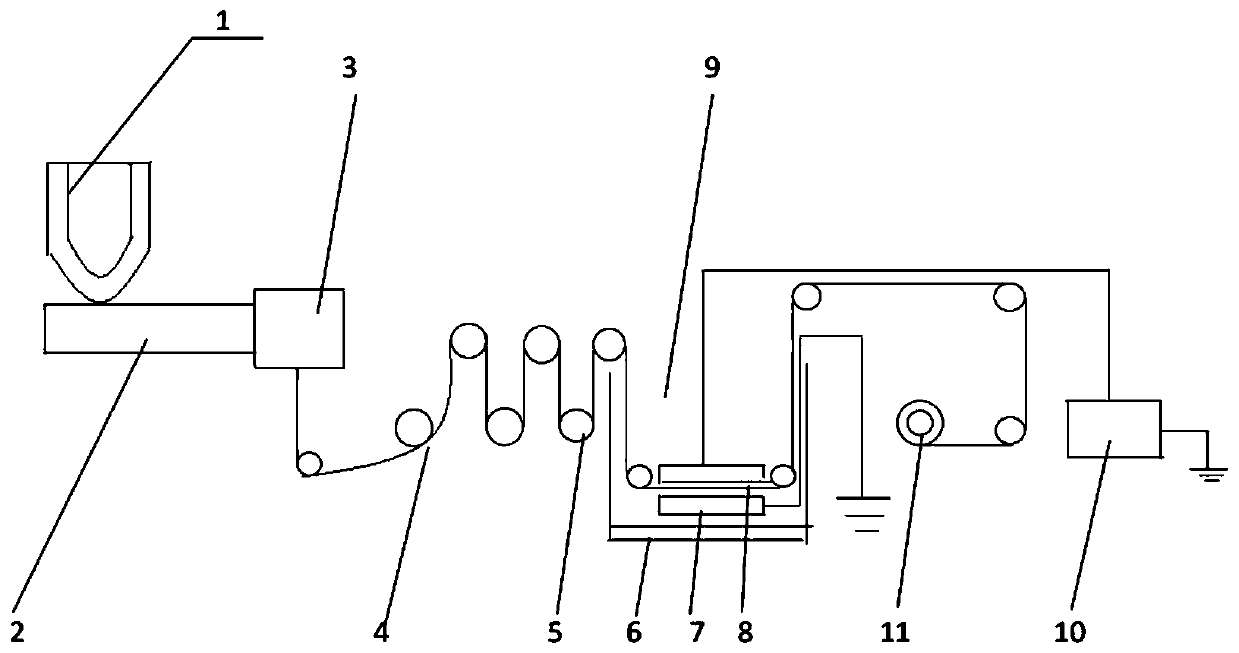

[0026] The present invention is a device for continuous production of piezoelectric fibers, such as figure 1 As shown, it includes a melt spinning device connected in sequence, a water cooling roller 4, a temperature control roller 5, a polarizing device and a collection roller 11. The melt spinning device includes a spinning box 2, and the upper surface of the spinning box 2 is connected with a material Spinneret 3 is connected to the end of bucket 1 and spinning box 2, and the polarization device includes a polarization pool, which is equipped with silicone oil, and two opposite high-voltage electrode plates 7 are arranged in parallel in the silicone oil, two A fiber traveling channel is formed between the high-voltage electrode plates 7, and a slow roller is provided at one end of the fiber traveling channel near the spinning box 2, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com