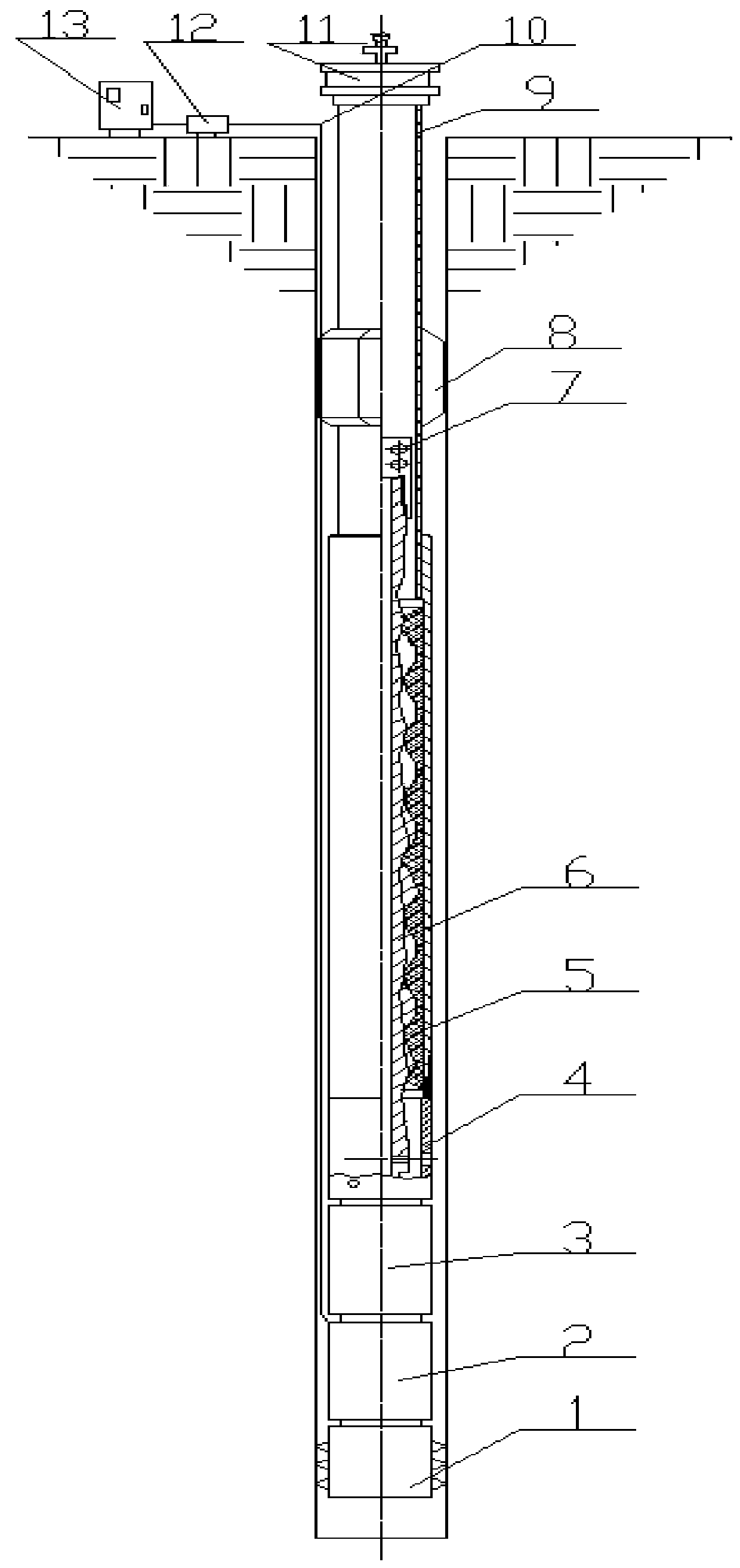

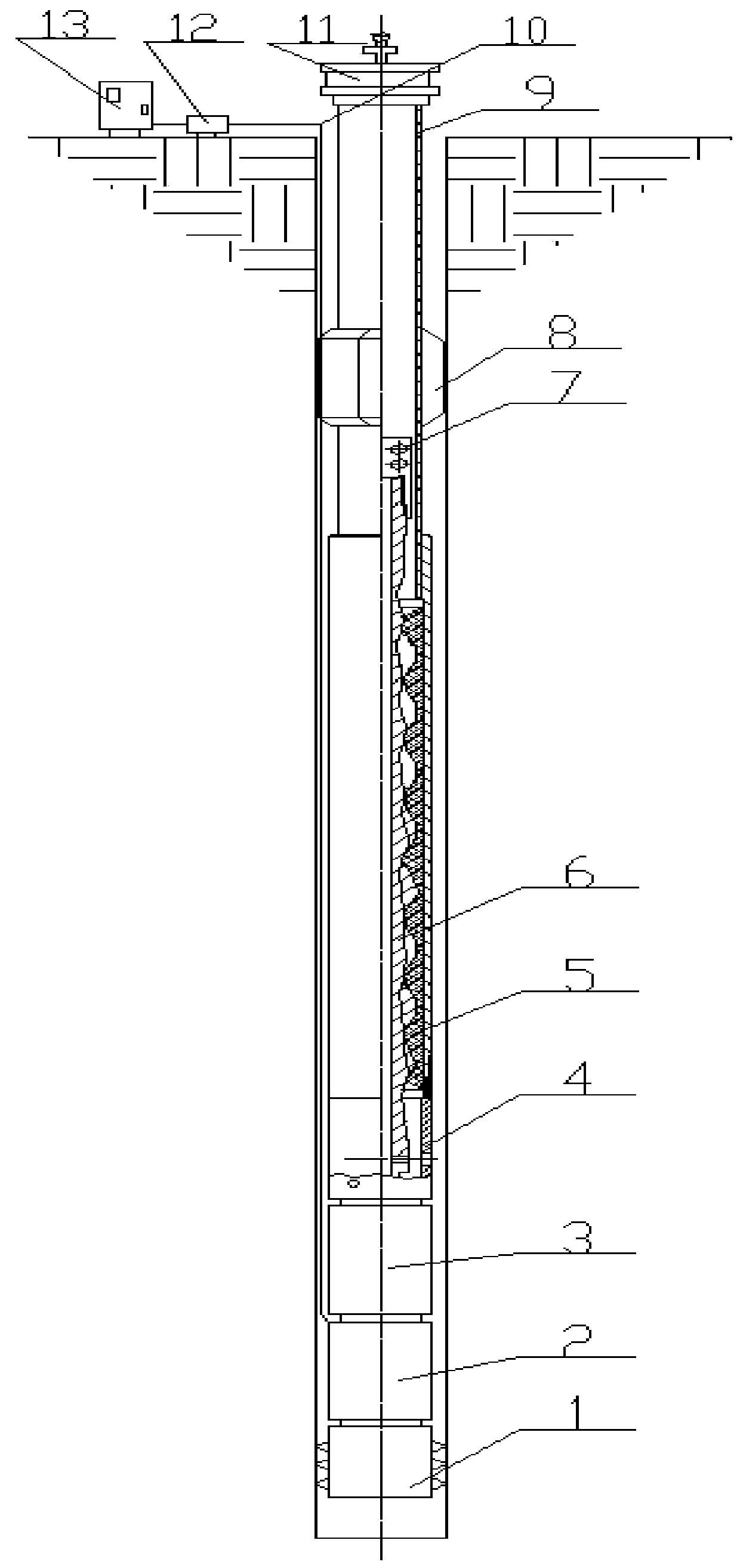

Oil-submerged hollow rotor screw pump oil extraction device

A technology for hollow rotors and oil extraction devices, which is applied to isolation devices, rotary piston pumps, pumps, etc., can solve the problems of lack of controllable heat-washing channels, pressure cannot be released, balanced, and heat-washing channels cannot be established, etc., to achieve The effect of reducing the risk of rotor pressure failure, reducing daily maintenance and operating costs, improving reliability and technical adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] Specific embodiments: the present invention will be described in further detail below in conjunction with the accompanying drawings. Washing valve 7, centralizer 8, tubing 9, submersible cable 10, wellhead 11, junction box 12, ground control cabinet 13; wherein the anchor tool 1 and submersible motor 2 are threaded, and the motor protector 3 is connected to the submersible The motor 2 is flange-connected, the motor protector 3 and the coupling 4 are flange-connected, the coupling 4 and the screw pump stator 5 are threaded, the coupling 4 and the screw pump hollow rotor 6 are threaded, and the screw pump The stator 5 is threaded to the tubing 9, the top of the hollow rotor 6 of the screw pump is threaded to the hot wash valve 7; the submersible cable 10 passes through the tubing centralizer 8 and is flanged to the submersible motor 2 in the well, and the upper part passes through the wellhead 11 to connect with the wiring Box 12 and ground control cabinet 13 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com