Compression-resistant aluminum pipe

An aluminum tube and inner layer technology, applied in the direction of tubes, rigid tubes, pipeline protection, etc., can solve problems such as the effect of aluminum tubes, tube wall deformation, aluminum tube leakage, etc., to enhance the compressive strength, reduce corrosion, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

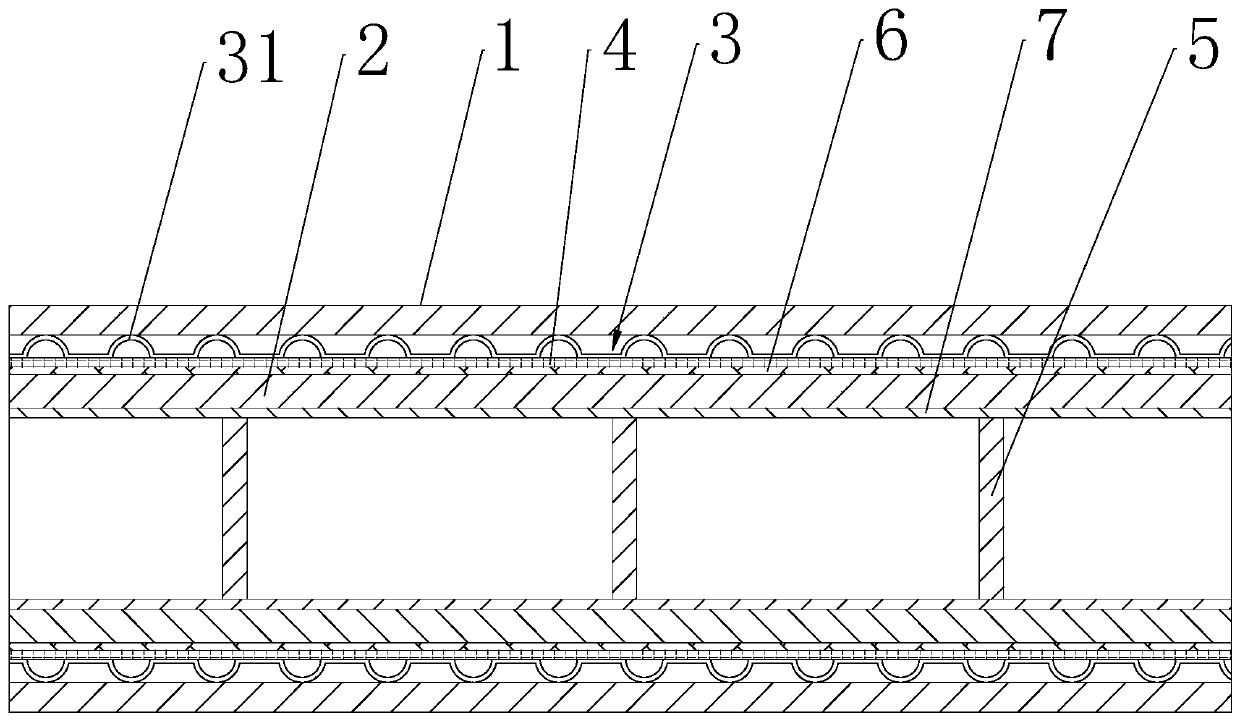

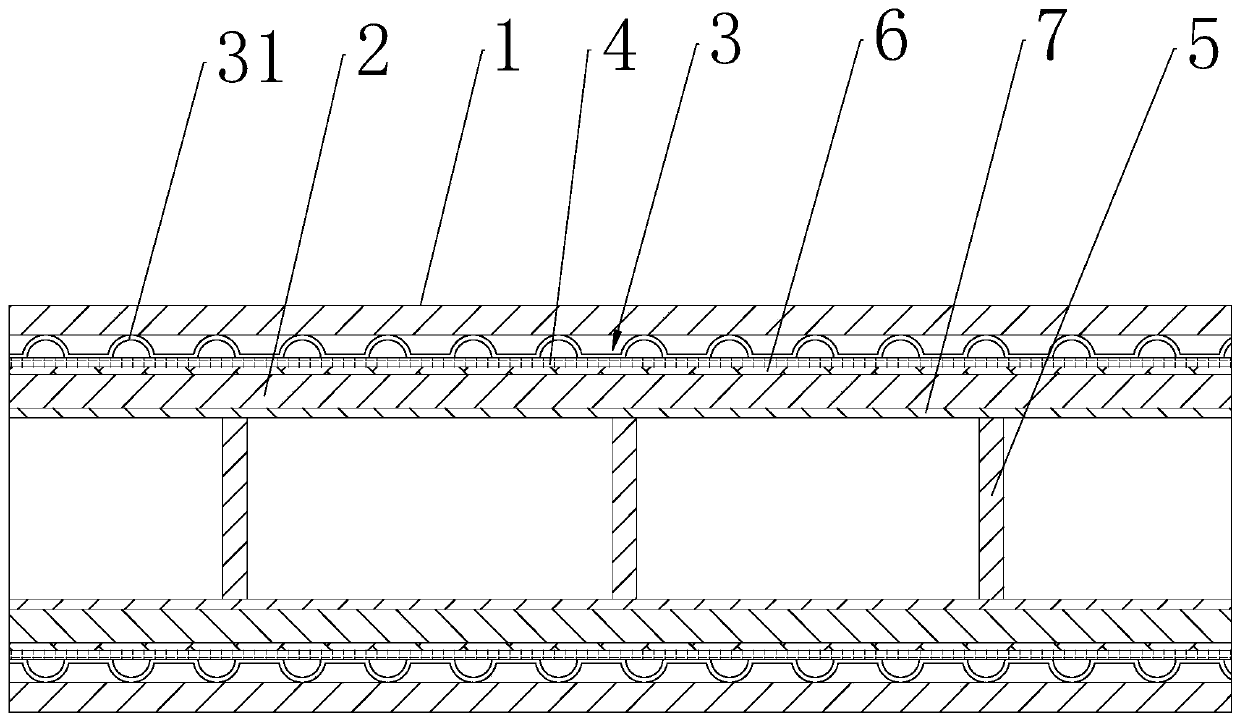

[0020] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0021] Such as figure 1 , a compression-resistant aluminum tube, comprising an outer aluminum tube 1 and an inner aluminum tube 2 arranged in the outer aluminum tube 1 .

[0022] Such as figure 1 A plurality of partitions 5 are fixedly connected to the inner aluminum tube 2 , and the partitions 5 are arranged along the length direction of the inner aluminum tube 2 . The separator 5 enhances the mechanical strength of the aluminum tube and improves the deformation resistance of the hollow aluminum tube.

[0023] Such as figure 1 The outer wall of the inner aluminum tube 2 is coated with a layer of metal mesh layer 4, and the metal mesh layer 4 is braided by brass. Brass has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com