Shaft type part measurement device based on sensing technology and measurement method thereof

A technology of shaft parts and measuring devices, applied in the field of shaft parts measuring devices based on sensing technology, can solve the problems of complicated operation and low measurement accuracy, and achieve the effects of high detection accuracy, simple mathematical operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

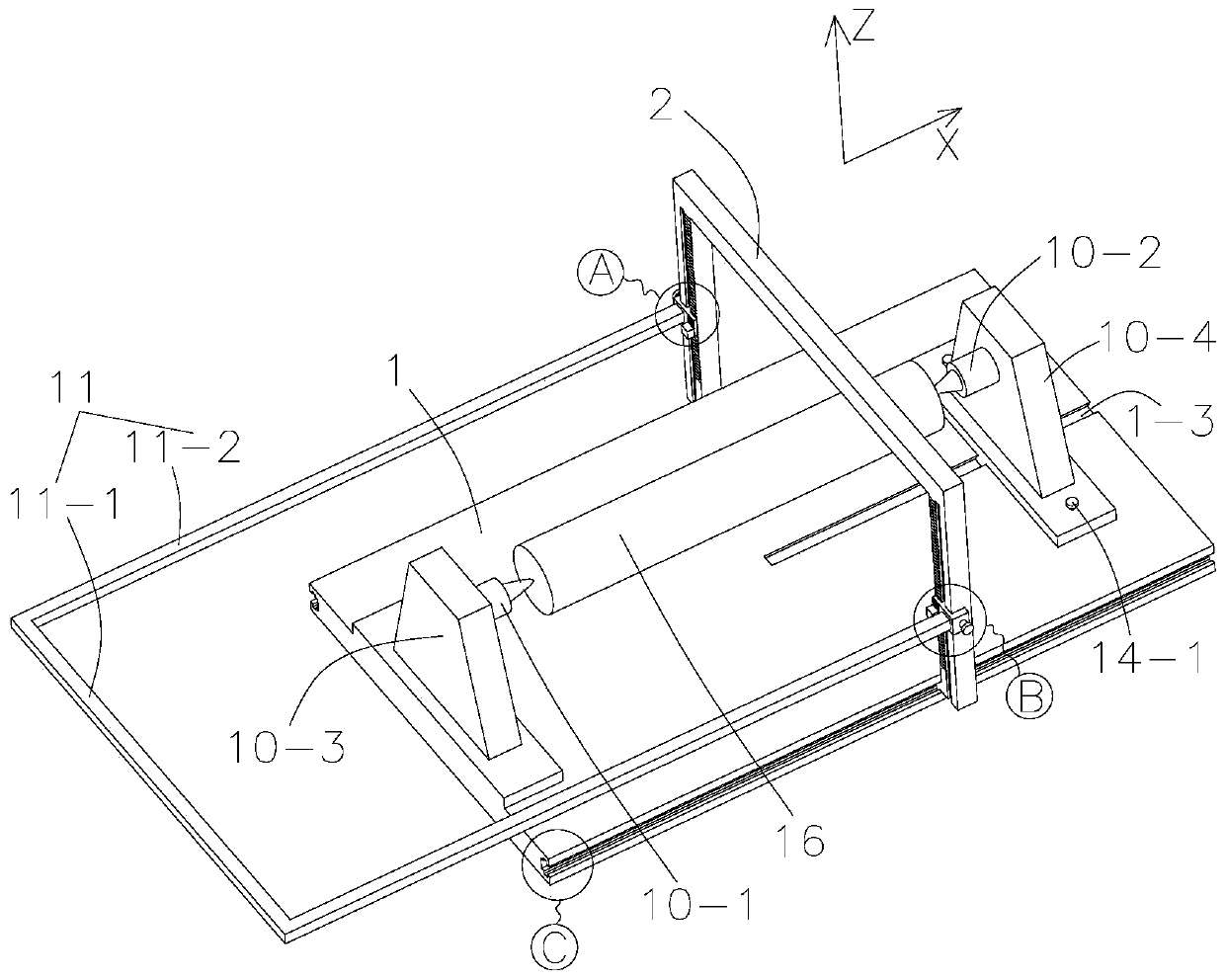

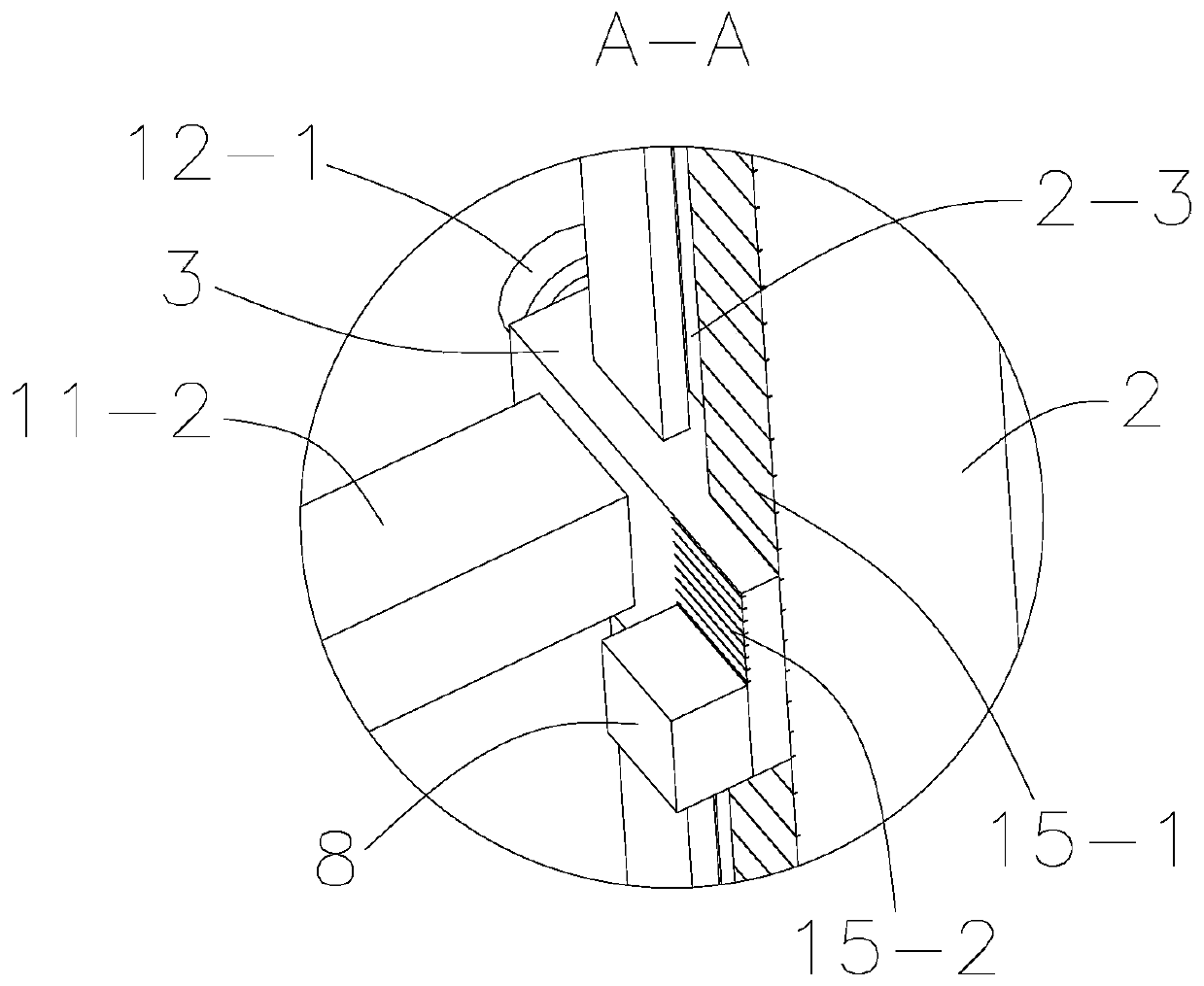

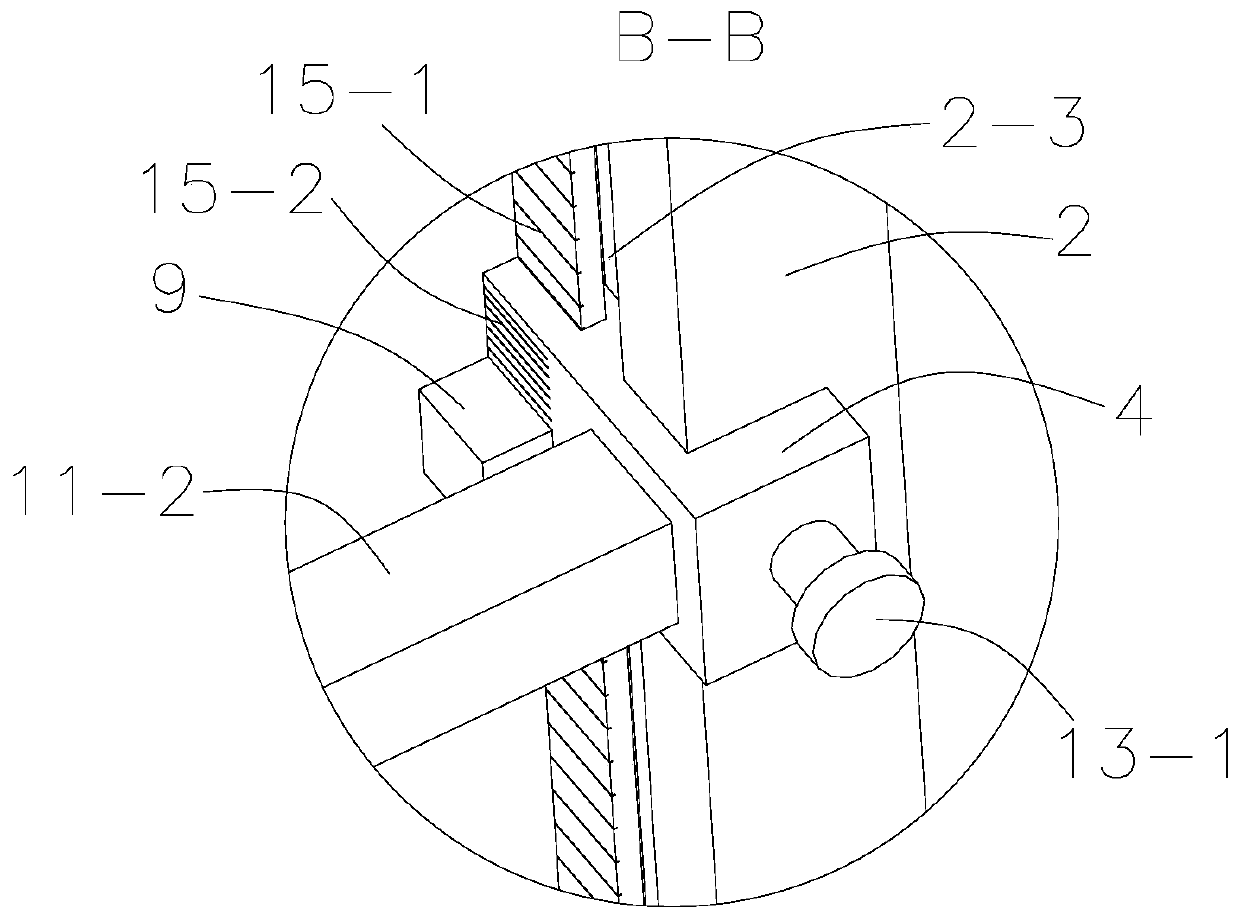

[0030] like Figure 1~6 As shown, a shaft part measuring device based on sensing technology includes a base 1, a gantry measuring frame 2, a first measuring ruler 3, a second measuring ruler 4, a signal conditioner 5 and a computer 7. The gantry measuring The bottom end of the frame 2 is slidably connected with the base 1 along the X direction, and the first measuring ruler 3 and the second measuring ruler 4 are respectively slidably arranged on both sides of the gantry measuring frame 2 along the Z direction, and the X direction and the Z direction are mutually In the direction of the vertical coordinate axis, in order to improve the measurement accuracy, both sides of the gantry measuring frame 2 are engraved with a large scale 15-1 along the Z direction, and the first measuring ruler 3 and the second measuring ruler 4 are along the Z direction. A small scale 15-2 coordinating with the large scale 15-1 is evenly engraved; a first sensor 8 is fixedly arranged on the first mea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap