Portable triaxial stress strain test device loaded by reaction force

A technology of counter force loading and triaxial stress, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of low intelligence level and difficult triaxial stress and strain experiments, and achieve transmission High efficiency, enhanced portability, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

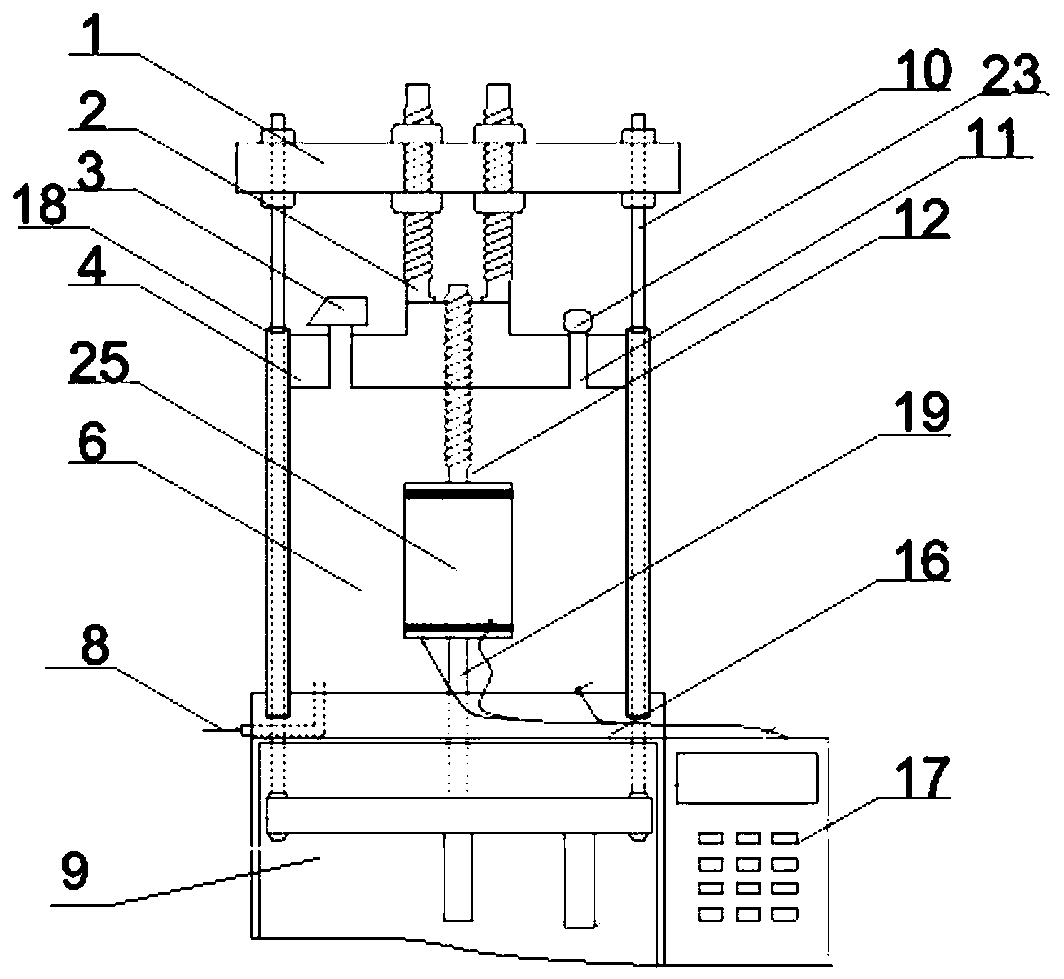

[0030] Depend on figure 1 As shown, the present invention is a portable triaxial stress-strain testing device using counter force loading, including an experimental device, a sensor group, a power loading device 9 and a servo motor 17 .

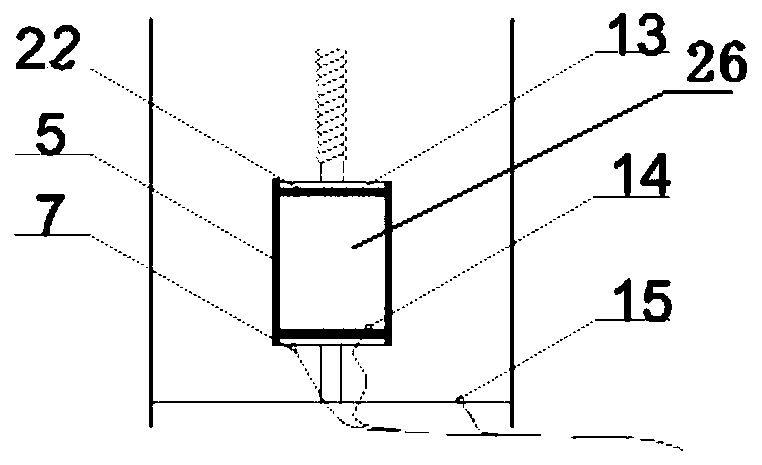

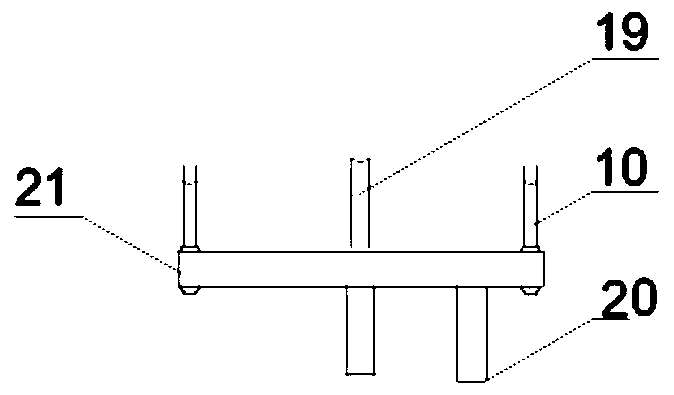

[0031] Described experimental device comprises a rectangular counter force beam 1, a rectangular confining pressure loading beam 21, two rigid transmission rods 10, two stainless steel hollow cylinders 18, a pressure chamber 6 and a sample package placed in the pressure chamber 6 25. The reaction force beam 1, the confining pressure loading beam 21, the pressure chamber 6 and the sample package 25 are kept concentric.

[0032] The pressure chamber 6 is a circular hollow device. In this embodiment, there is a counterforce piston 4 on the upper part of the pressure chamber, and a pressure chamber base 16 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com