Double-sided photoetching workpiece table based on double-mask alignment

A technology of double-sided lithography and workpiece stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the characteristics and advantages of the present invention more obvious and understandable, the specific implementation of the present invention will be described in detail below.

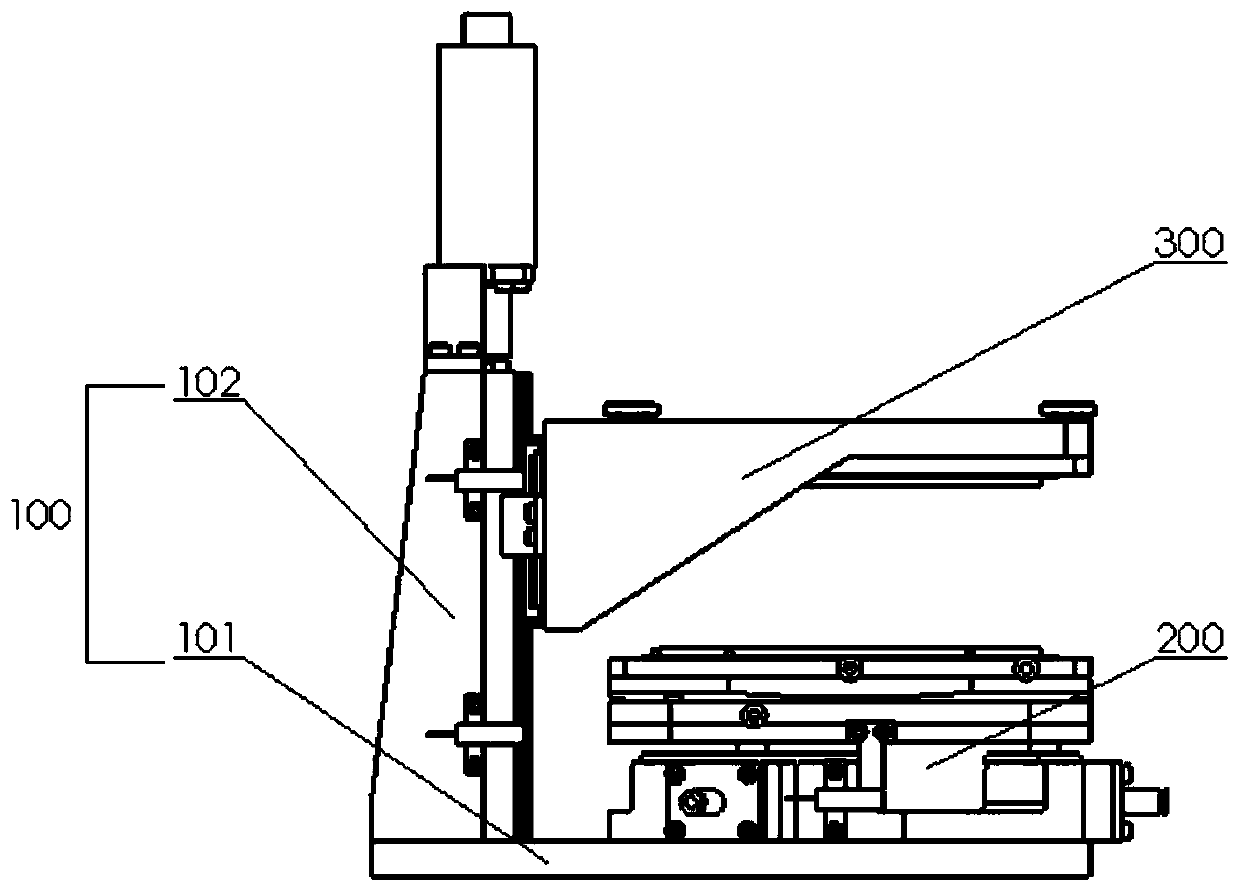

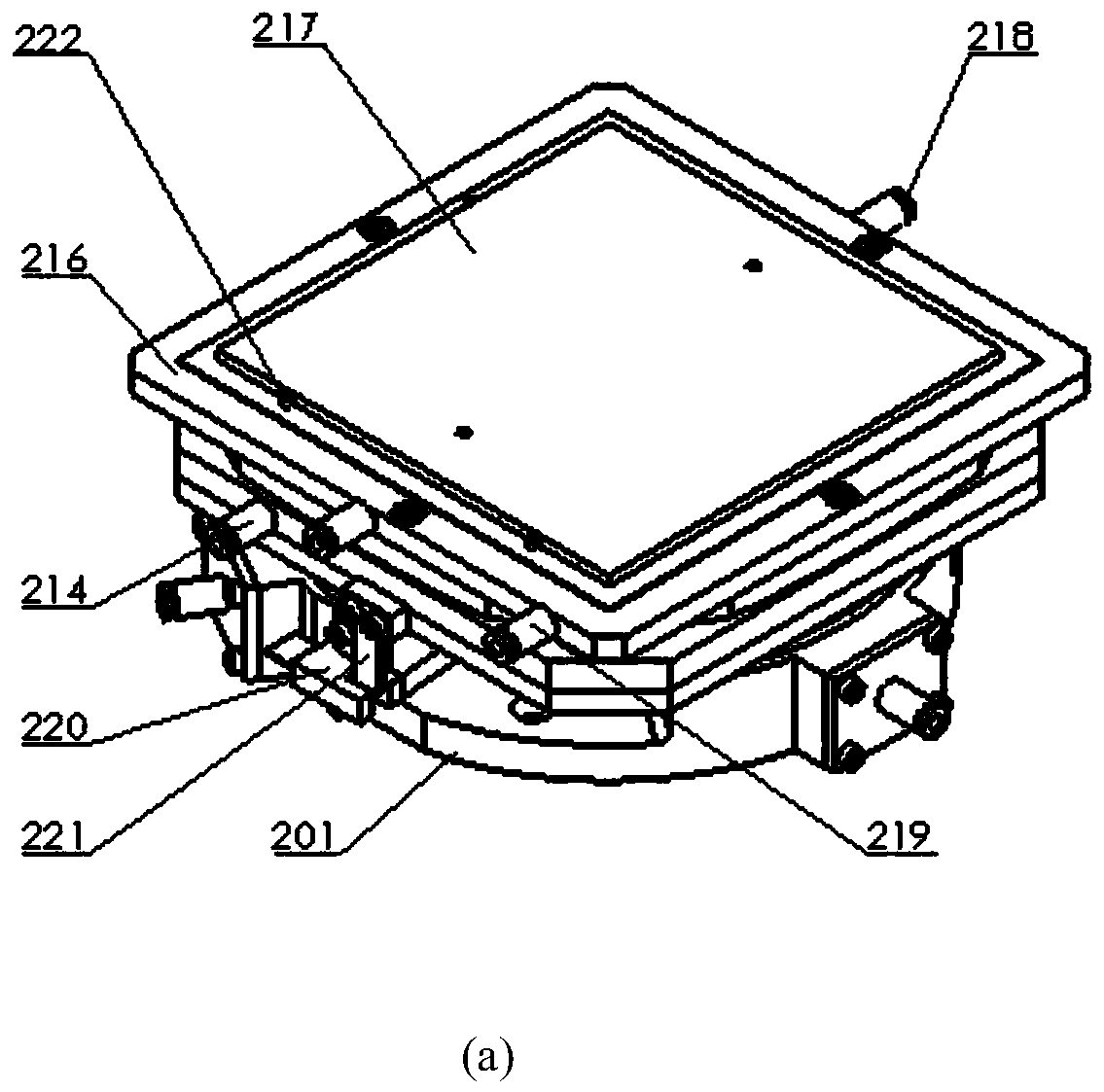

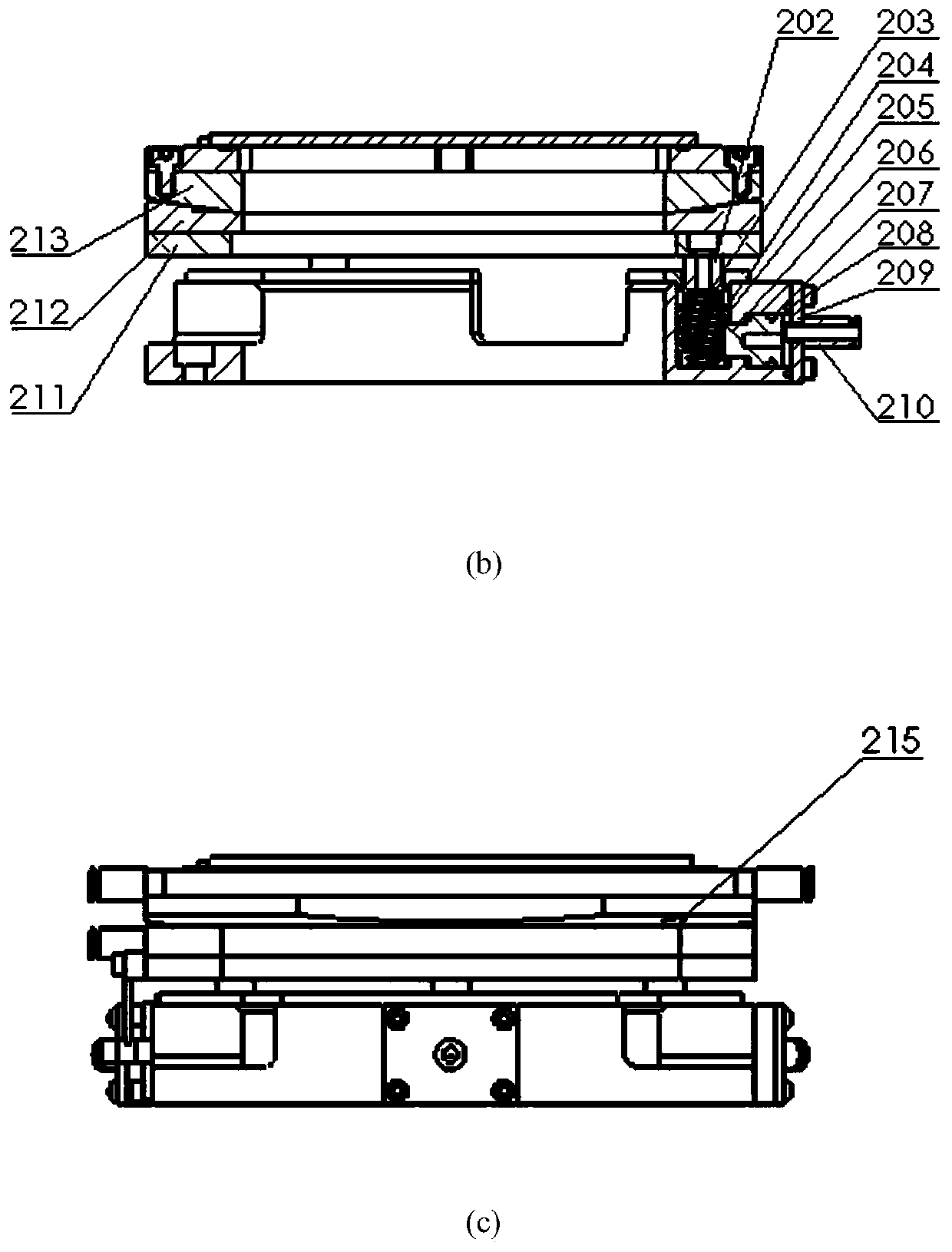

[0019] As shown in the figure, a double-sided photolithography workpiece table of the present invention includes a base 100, a lower mask leveling mechanism 200 and an upper mask lifting mechanism 300. The base 100 is the benchmark for the installation of the entire workpiece table. The bottom plate 101 is composed of a guide rail mounting seat 102, the bottom plate 101 is the substrate of the workpiece table, and the guide rail mounting seat 102 is connected to the bottom plate 101; the lower mask leveling mechanism 200 is arranged above the bottom plate 101 of the base 100 to realize The upper mask is leveled with the lower mask during the descent process; the upper mask lifting mechanism 300 is arranged on the guide rail mounting seat 102 of the base 100 to realize the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com