High-temperature reactor control rod system overhaul device and technology based on ergonomics

A technology of human factors engineering and control rods, which is applied in the field of maintenance of high-temperature gas-cooled reactor control rod systems, can solve the problems of large space in the atmosphere isolation cabin, complex atmosphere isolation process, and large safety risks, and achieve small atmosphere isolation space and low cost , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

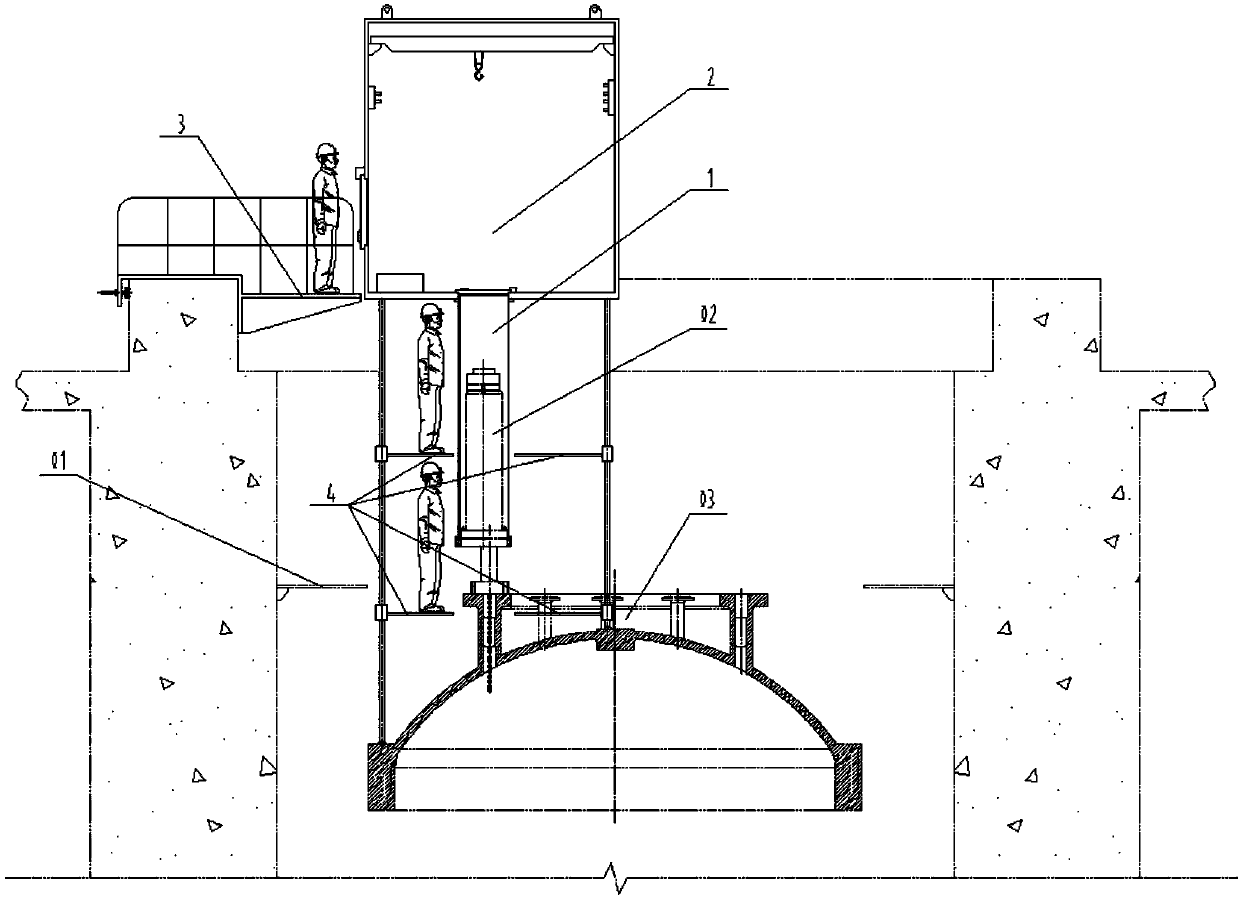

[0047] Such as figure 1 As shown, the high-temperature gas-cooled reactor control rod drive mechanism maintenance equipment of the present invention includes an atmosphere-isolated main compartment 1, a transition compartment 2, a maintenance platform 4 and a corridor 3;

[0048] Atmosphere isolation The main compartment 1 and the transitional compartment 2 are two airtight compartments with inner cavities isolated from the outside world, and the communication or isolation between the two is controlled by an automatic opening and closing hatch II21;

[0049] When it is necessary to disassemble and overhaul the control rod driving mechanism, first install the whole set of overhaul equipment in place, open the hatch door II21 between the two compartments, and replace the gas in the atmosphere-isolated main compartment 1 and transition compartme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com