Array substrate, display panel and transfer method of micro LED

An array substrate and miniature technology, which is applied to electrical components, electric solid-state devices, circuits, etc., can solve the problems of complex display panel preparation process, and achieve the effect of simplifying the setting process and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

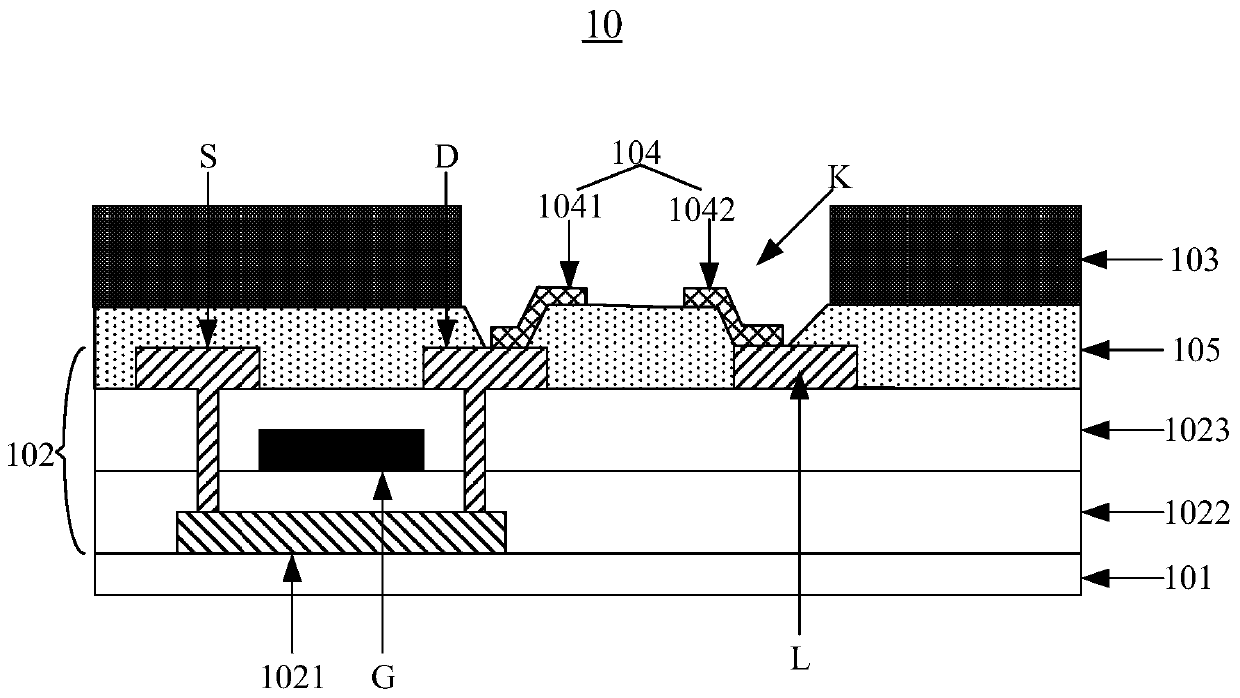

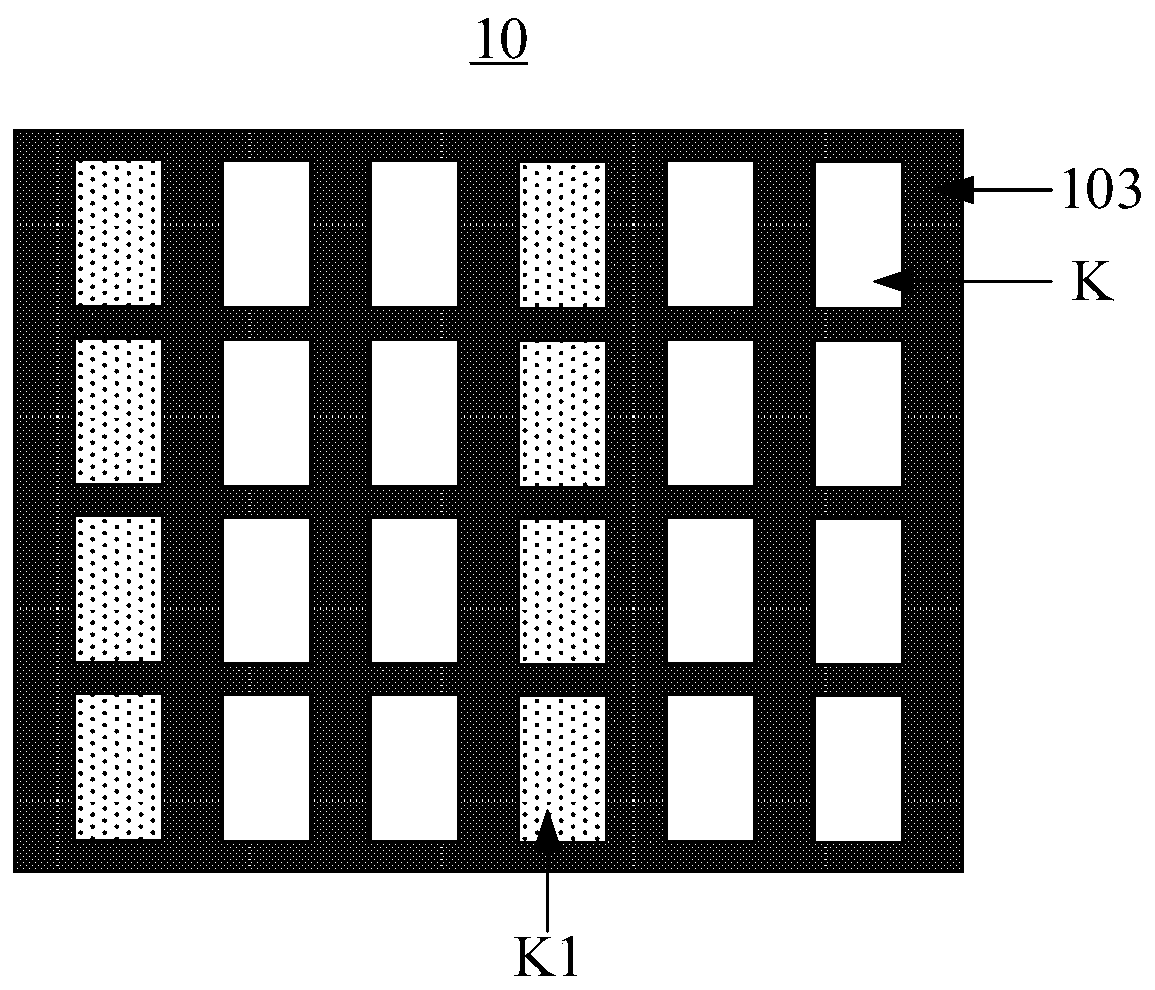

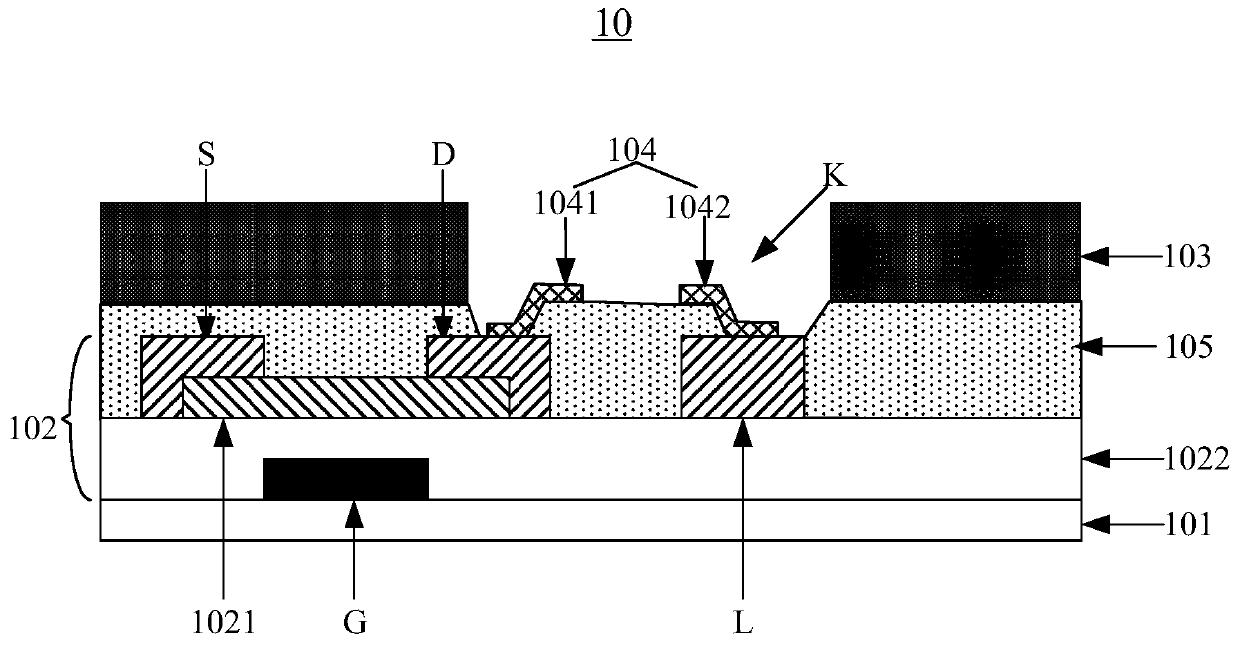

[0070] In order to make the purpose, technical solution and advantages of the present application clearer, the implementation manners of the present application will be further described in detail below in conjunction with the accompanying drawings.

[0071] To prepare the Micro LED display panel, the Micro LED needs to be transferred to the array substrate. In the related art, an elastic die with adjustable adsorption force is used to transfer Micro LEDs. The transfer process includes: adjusting the adsorption force of the elastic die, so that the elastic die can absorb multiple Micro LEDs at one time. The multiple Micro LEDs are placed on the elastic die. The arrangement method on the array substrate is the same as the arrangement method of multiple pixel areas in the array substrate; the elastic stamper with the Micro LEDs adsorbed is moved to the top of the array substrate, and the Micro LEDs are aligned with the pixel areas on the array substrate; The adsorption force of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com