NFMC corrosion-resistant composite mold pressing color steel cable bridge

A cable tray and composite mold technology, applied in electrical components and other directions, can solve the problems of transportation and construction lifting difficulties and high manufacturing costs, and achieve the effects of improving load stability, saving raw materials, and enhancing torsion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

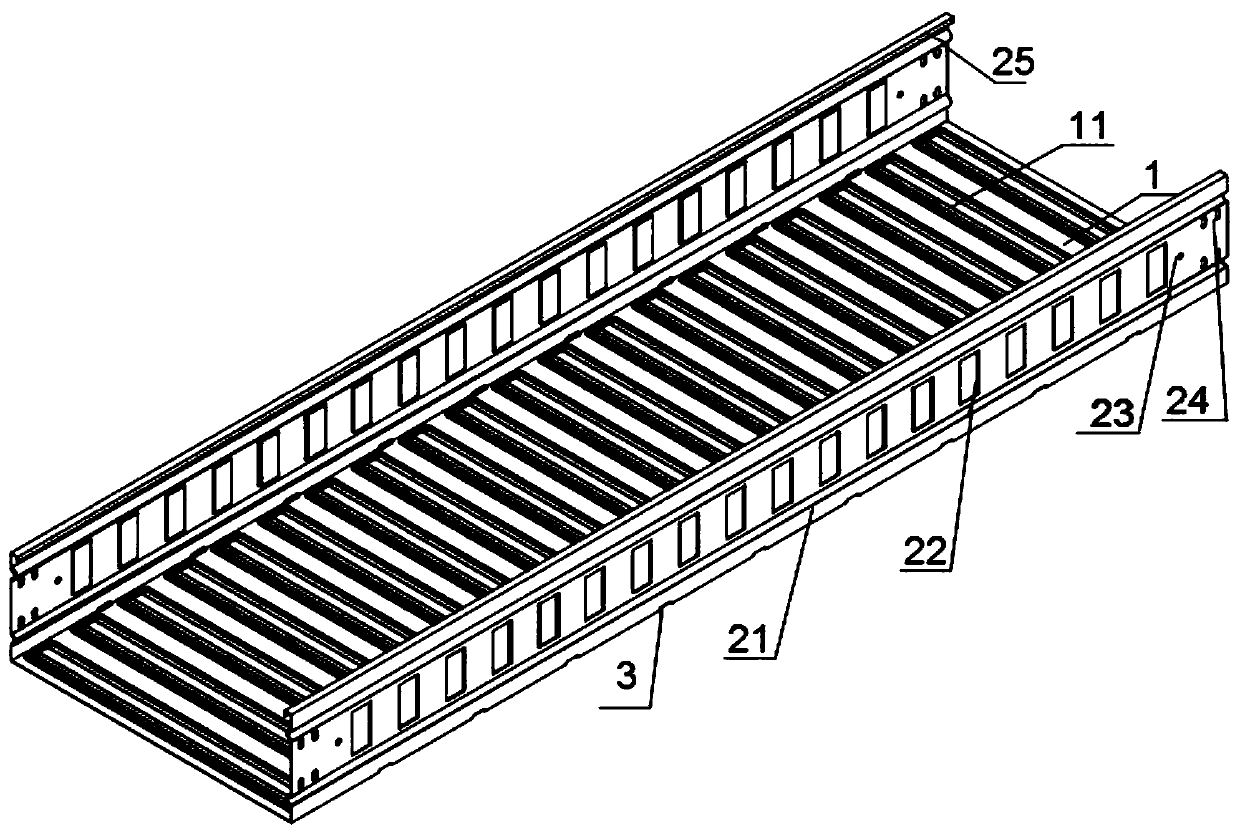

[0027] like figure 1 As shown, a NFMC corrosion-resistant composite molded color steel cable bridge comprises a bottom plate 1 and side plates 2 arranged on both sides of the bottom plate, and the bottom plate 1 and the side plates 2 are integrally stamped and formed with metal materials; There are angular bosses 3 punched at the connection of the horns; The angular boss enhances the strength between the bottom plate 1 and the side plate 2, enhances the torsional force between the side plate and the bottom plate, and improves the load stability. In normal use, when a downward force is applied to the bridge frame, the side plate will be twisted, and the angular boss is added, which is equivalent to adding a reinforcing rib between the side plate and the bottom plate, and does not affect the cable arrangement in the bridge frame. .

[0028] When the height of the bridge frame is less than or equal to 100 cm, a side plate reinforcing rib 21 is provided on the side plate 2 . Th...

Embodiment 2

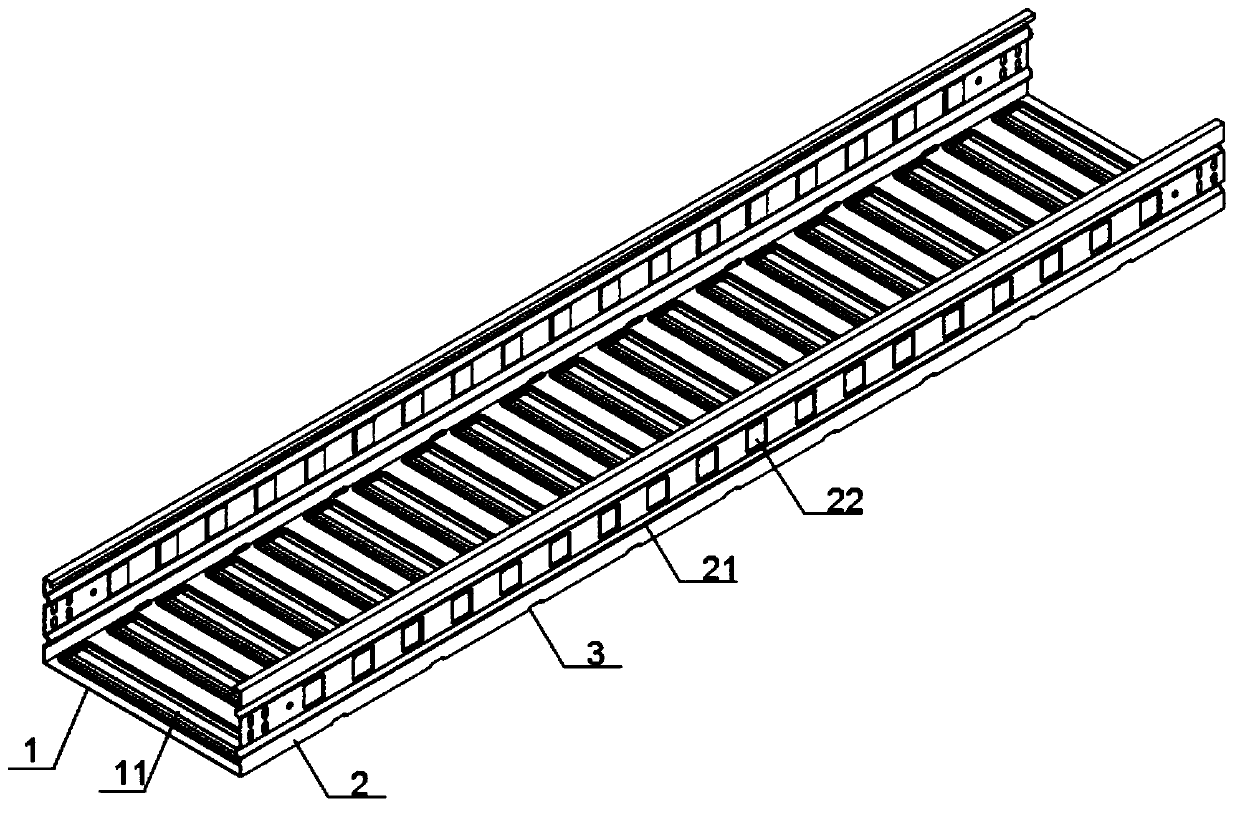

[0041] The difference between this embodiment and Embodiment 1 is: in this embodiment, when the height of the bridge frame is greater than 100CM, there are two side plate reinforcing ribs 21 of the side plate 2, and the two reinforcing ribs 21 are parallel to each other.

[0042] like figure 2 As shown, a NFMC corrosion-resistant composite molded color steel cable bridge comprises a bottom plate 1 and side plates 2 arranged on both sides of the bottom plate, and the bottom plate 1 and the side plates 2 are integrally stamped and formed with metal materials; There are angular bosses 3 punched at the connection of the horns; The angular boss 3 enhances the strength between the bottom plate 1 and the side plate 2, enhances the torsional force between the side plate and the bottom plate, and improves the load stability. In normal use, when a downward force is applied to the bridge frame, the side plate will be twisted, and the angular boss is added, which is equivalent to adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com