Production method of rims of integrated engineering vehicle

A production method and engineering technology, applied in the field of production of one-piece engineering wheel rims, can solve the problems of high manufacturing cost, unqualified, difficult to meet standards, etc., and achieve the effect of improving roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific examples.

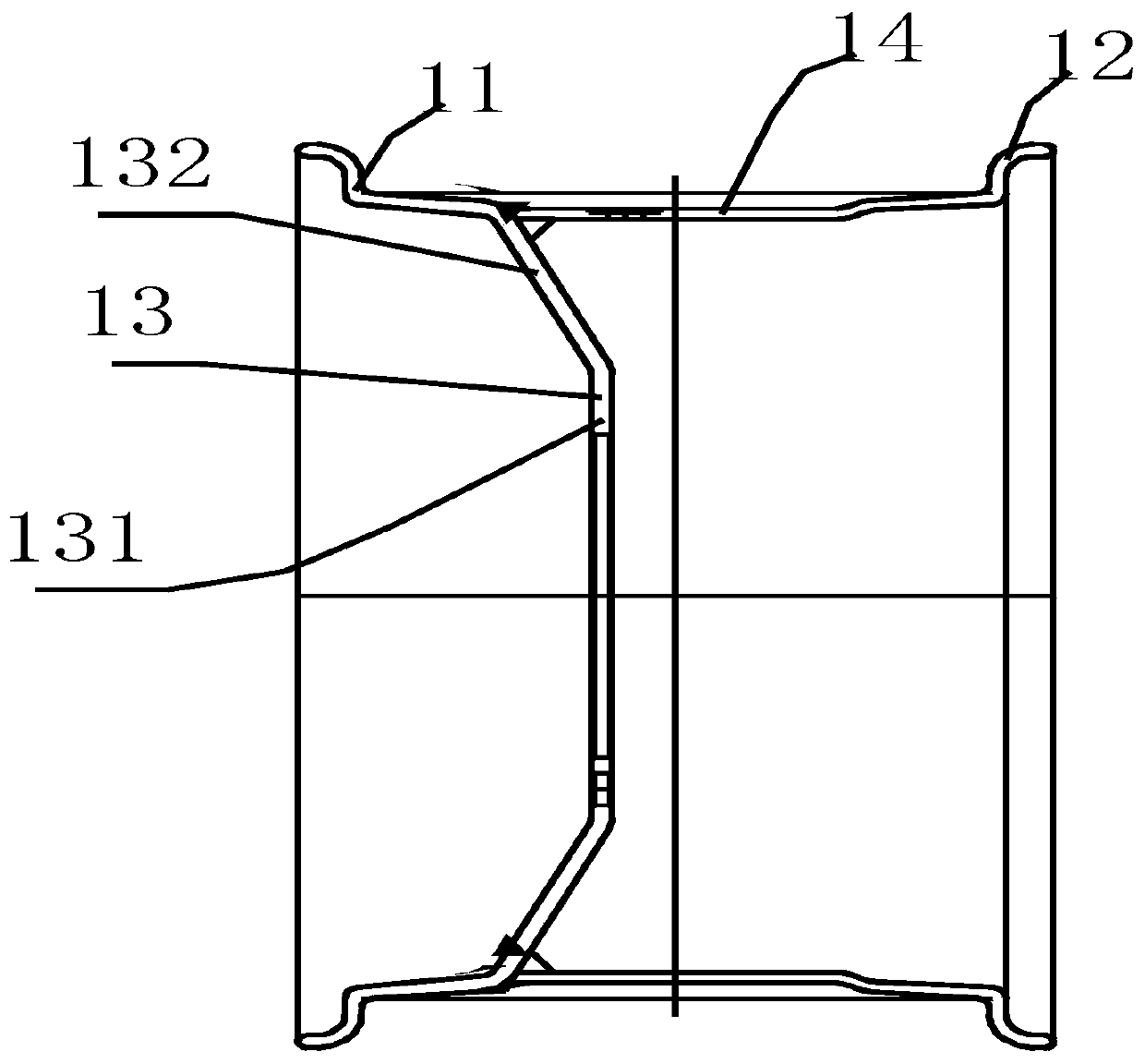

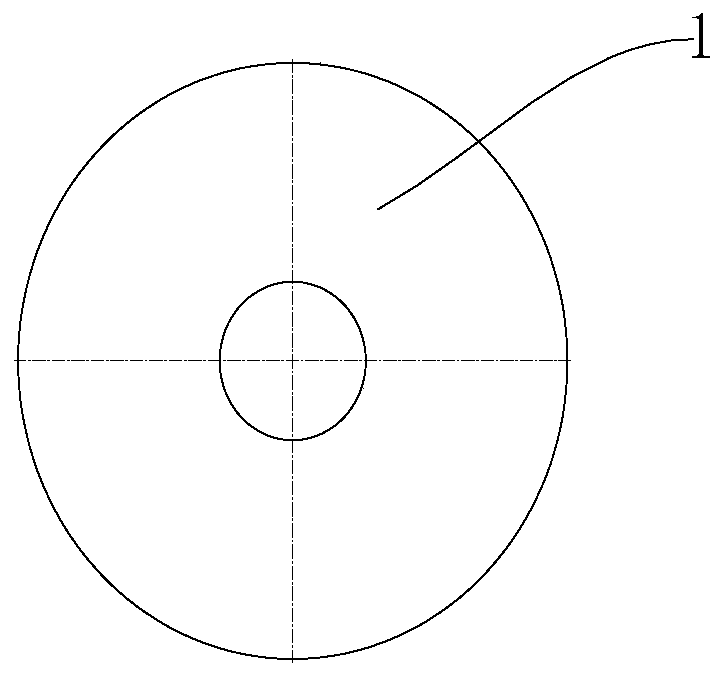

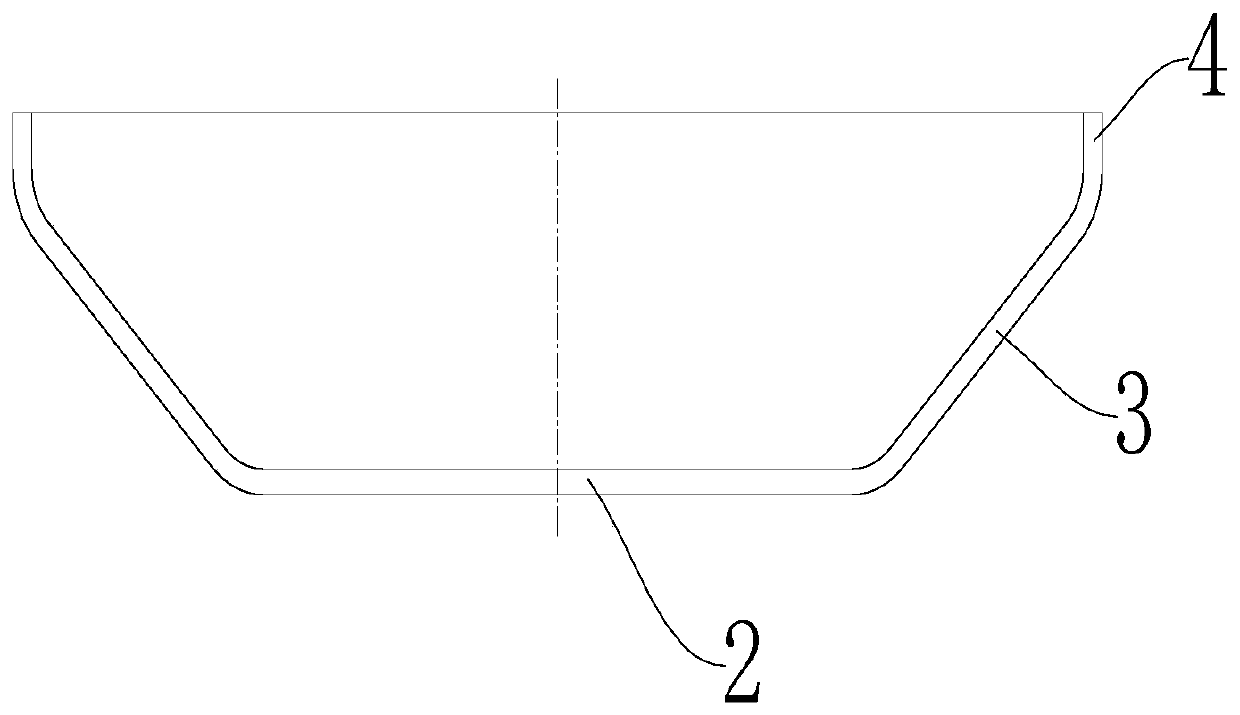

[0037] Such as Figure 1-10 As shown, the production method of a one-piece engineering wheel rim, the engineering wheel rim includes an outer retaining ring 11, an inner retaining ring 12, a wheel spoke 13, and a wheel rim 14, which is characterized in that the wheel rim and the inner retaining ring are integrally formed to form part B;

[0038] The outer retaining ring and the spokes are integrally formed to form part A, and part A and part B are welded and fixed, or

[0039] The spoke and part B are integrally formed to form part C, and the outer retaining ring is welded and fixed with part C;

[0040] The spokes are curved spokes, the spokes include a spoke body 131, and the two ends of the spoke body are bent outward to form a bending section 132, and the spokes adopt the design of curved spokes, which improves the support strength of the spokes and the overall support st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com