A spiral sand washing machine with self-setting micro-washing function

A sand washing machine and screw technology, applied in the field of sand washing, can solve the problems of many impurities, poor sand washing effect, and difficulty in effectively removing impurities, etc., and achieve the effect of improving the elution effect and the elution effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

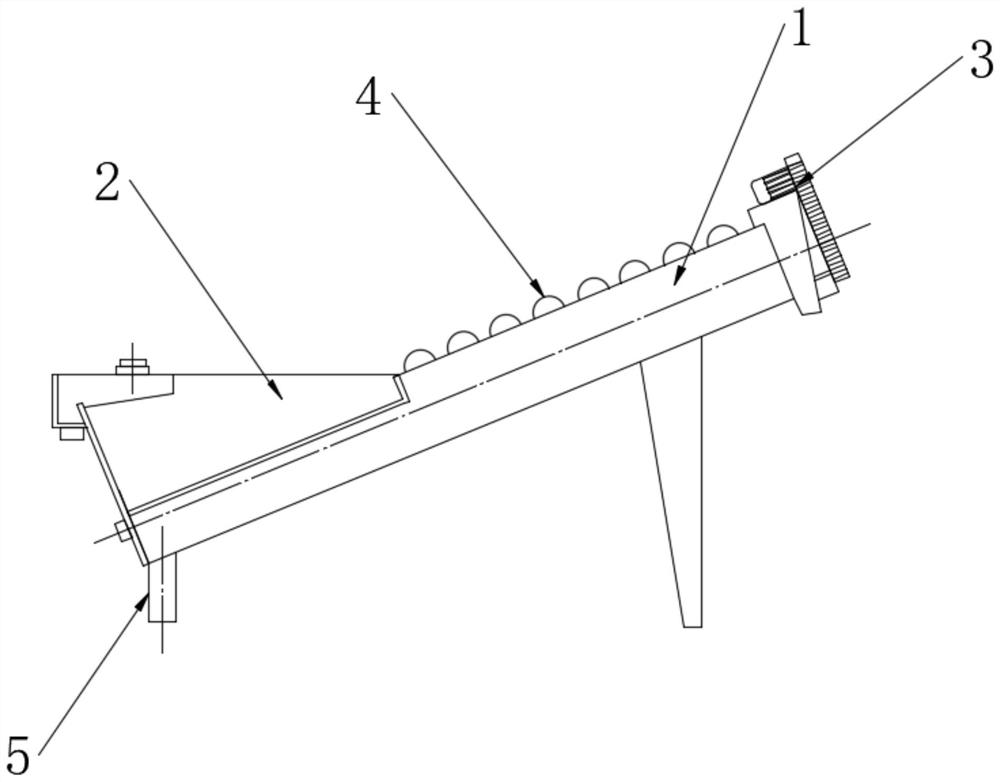

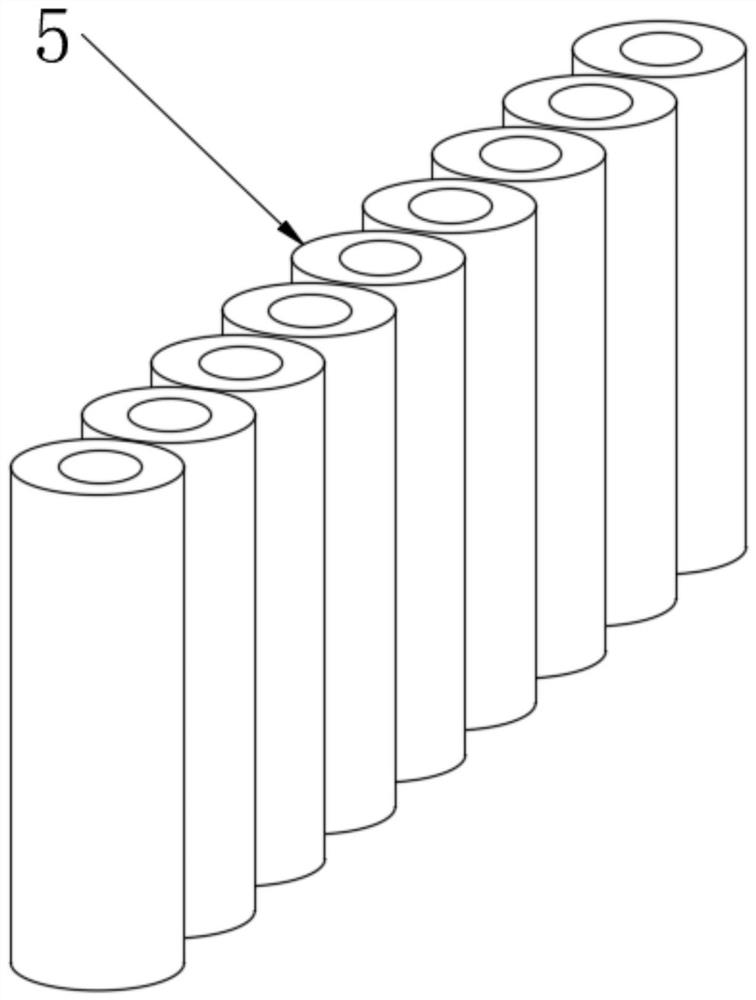

[0040] see Figure 1-2 , a spiral sand washing machine with self-setting micro-washing function, including a frame 1, a pair of spiral entities 4 are installed in the frame 1, a drive system 3 is installed at one end of the frame 1, and the connection between the drive system 3 and the spiral entity 4 The other end of the frame 1 is equipped with an overflow tank 2. The above are the existing technologies of the spiral sand washing machine. The specific structure and working principle will not be repeated here. The outlet of the frame 1 is fixedly installed with a row of uniform Distributed micro-washing drums 5, when the technician selects the micro-washing drums 5, the closer the particle size is to the sand and gravel, the better the micro-washing effect.

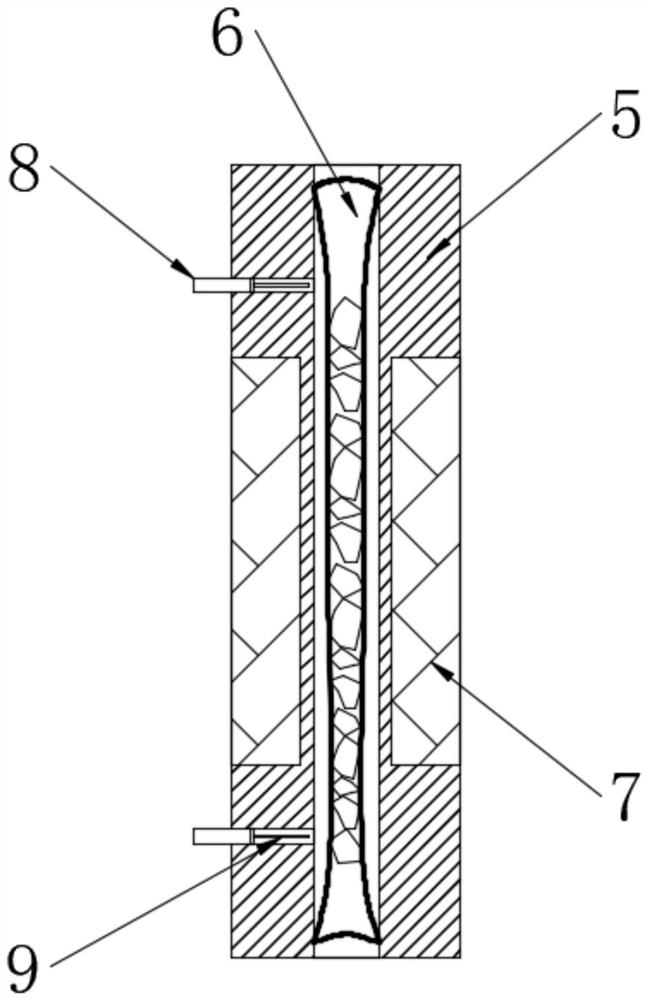

[0041] see Figure 3-4 , the inner wall of the micro-washing cylinder 5 is fixedly connected with a self-shaping laminating layer 6 along the circumferential direction, and the self-shaping laminating layer 6 is inlaid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com