Multifunctional robotic sucking disc rack

A suction cup rack and robot technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inability to adjust and affect the positioning of plate handling and processing, and achieve the effect of simple and compact structure, stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

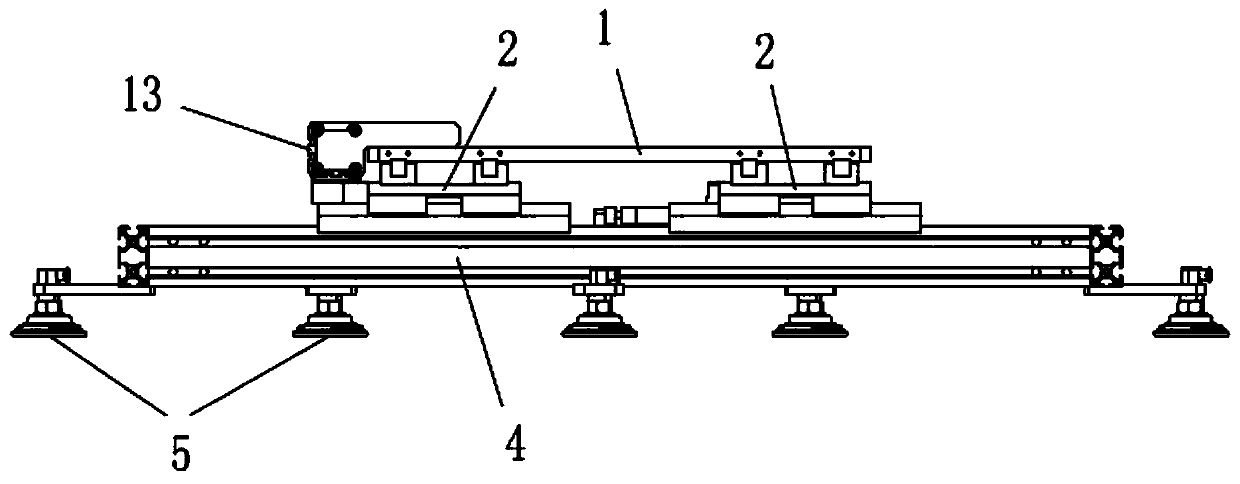

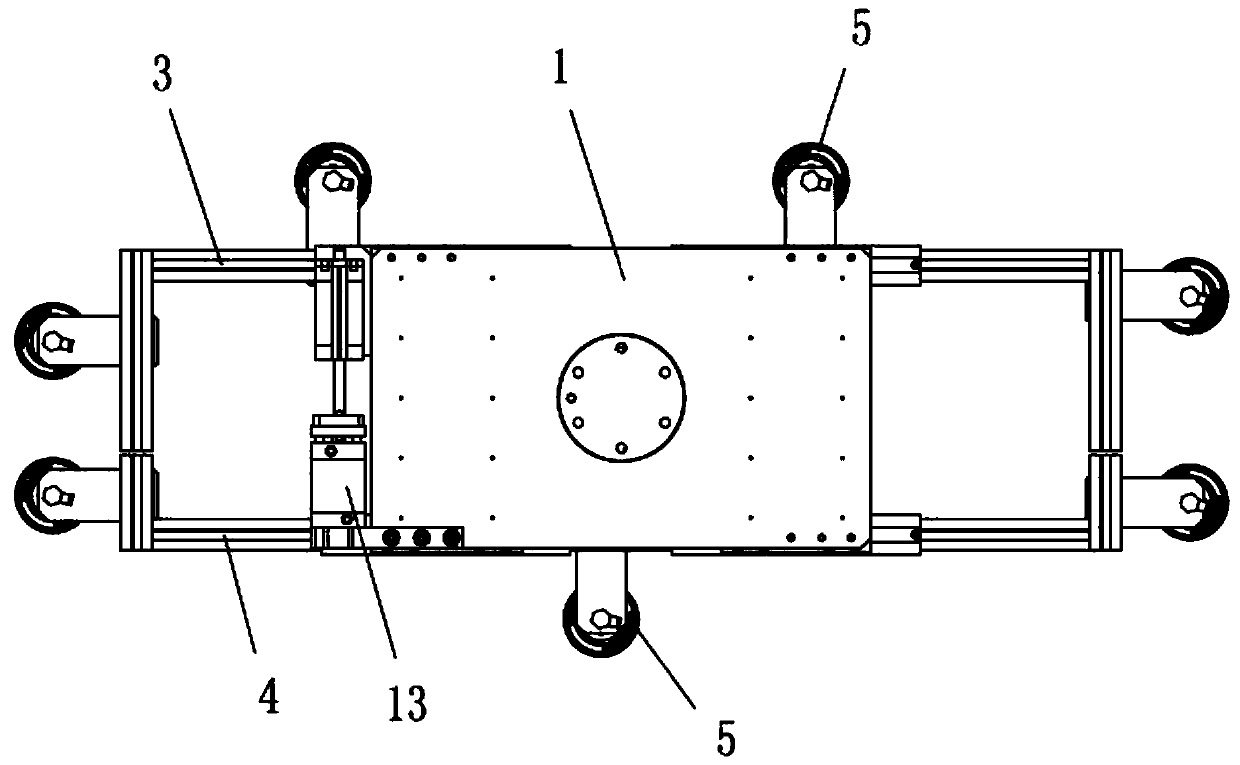

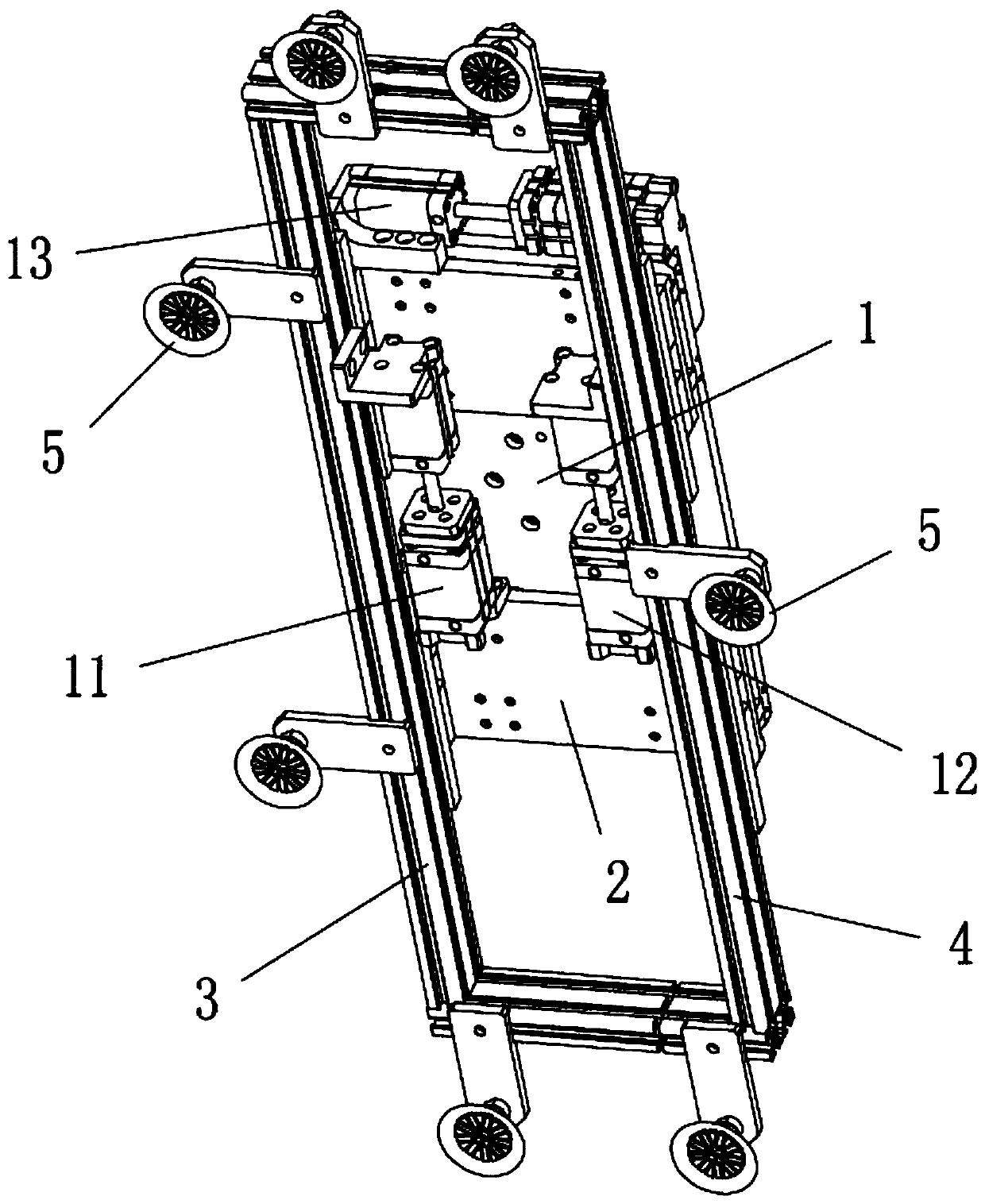

[0018] Such as Figure 1-3 As shown, a multifunctional robot suction cup frame according to the present invention includes a main connection plate 1, a secondary connection plate 2, a first suction cup frame 3 and a second suction cup frame 4; the main connection plate 1 is located on the secondary connection plate 2 The upper side of the upper side, the first suction cup frame 3 and the second suction cup frame 4 are located on the lower side of the auxiliary connecting plate 2; the first sucking cup frame 3 and the auxiliary connecting plate 2 are matched by the first mobile drive assembly 11 and the guide structure, The second suction cup frame 4 and the auxiliary connecting plate 2 cooperate with the guide structure through the second mobile drive assembly 12, and cooperate with the guide structure through the third mobile drive a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com