Leveling bearing assembly of dry method overall pavement of fabricated ground facing materials

A finishing material and prefabricated technology, applied in the direction of floors, local raised floors, covering/lining, etc., can solve the problems of easy mess, prolonged construction period, and many processes, so as to eliminate formaldehyde pollution and shorten construction period. , the effect of simplifying the program

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

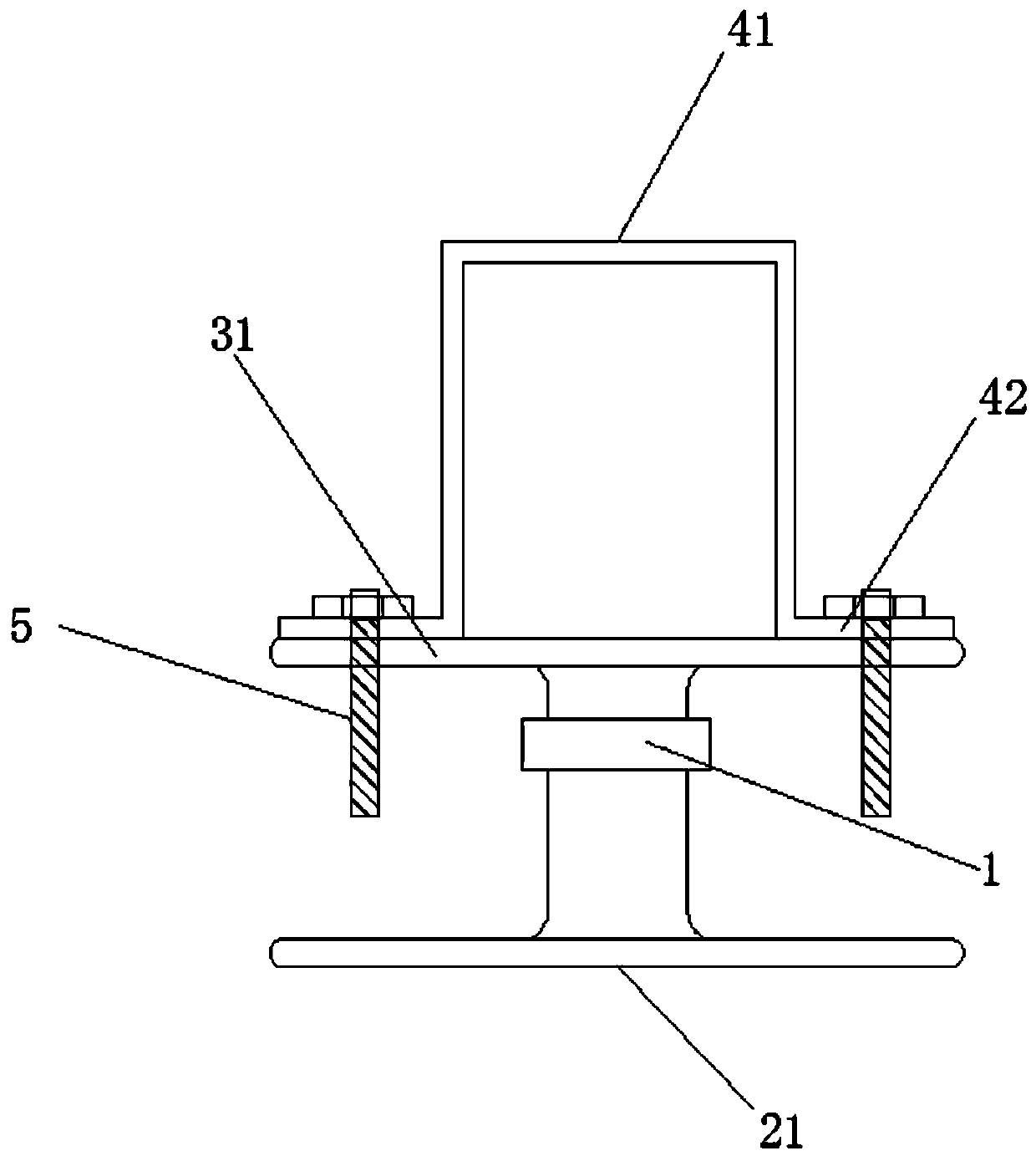

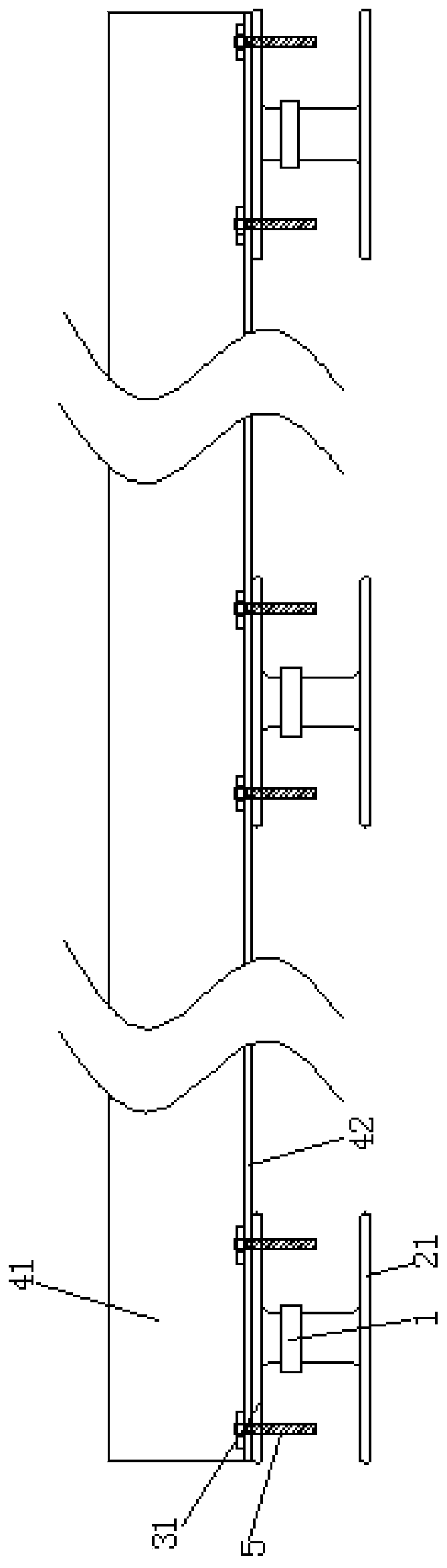

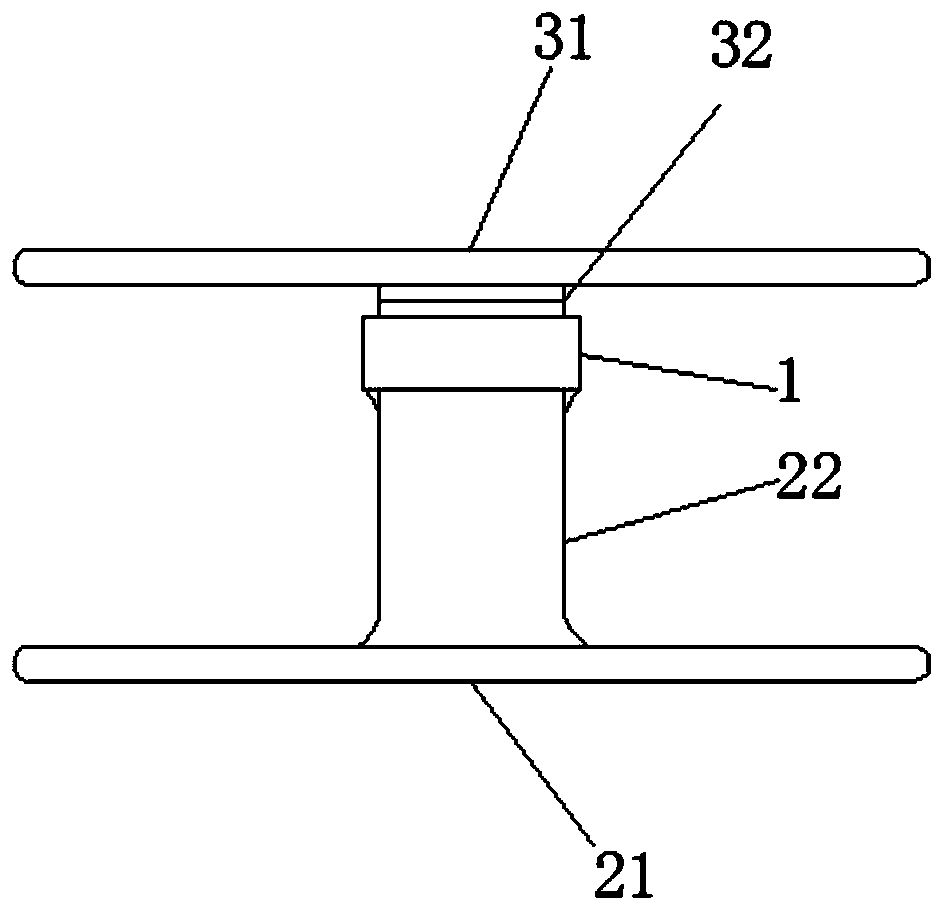

[0035] see Figure 1-4 , the figure shows a leveling and load-bearing assembly for dry overall paving of prefabricated floor facing materials provided by Embodiment 1 of the present invention, which includes multiple sets of leveling components arranged at intervals, and the leveling components include: A support seat, which includes a base, a support frame and an adjustment member 1, the base is provided with a bottom plate 21 and a first connecting rod 22, and the support frame is provided with a support plate 31 and a second connecting rod 32; the first connecting rod 22 is provided with The connecting hole 23 is threadedly connected with the second connecting rod 32 and the connecting hole 23; the adjustment member 1 is sheathed on the second connecting rod 32 and both are threaded; the carrier, the carrier is arranged on the supporting frame. Wherein, the adjustment member 1 is a nut, which is more convenient for adjustment.

[0036] A leveling and load-bearing assembly ...

Embodiment 2

[0044] see Figure 1-4, the figure shows a leveling load-bearing assembly for the dry integral paving of the prefabricated floor facing material provided by Embodiment 2 of the present invention. This embodiment further makes The following is an improved technical solution: the bottom plate 21 and the first connecting rod 22 are vertically arranged; the support plate 31 and the second connecting rod 32 are vertically arranged. Through the setting of the above structure, the supporting effect is optimal.

Embodiment 3

[0046] see Figure 1-2 , the figure shows a leveling load-bearing assembly for the dry overall paving of the prefabricated floor facing material provided by Embodiment 3 of the present invention. This embodiment further makes The following is an improved technical solution: the carrying frame includes a carrying plate 41 and connecting plates 42 arranged at the bottoms of both sides of the carrying plate 41 . Through the setting of the above structure, the connection strength is the best, and both sides are connected at the same time, so the stability and levelness are good. Among them, the bearing frame is an integrated structure, which further improves the rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com