A Reinforcement Method for Shield Access and Exit Holes in Ultra-deep Strata

A technology for entering and exiting holes and strata, which is applied in drilling equipment and methods, earthwork drilling, underground chambers, etc. The effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

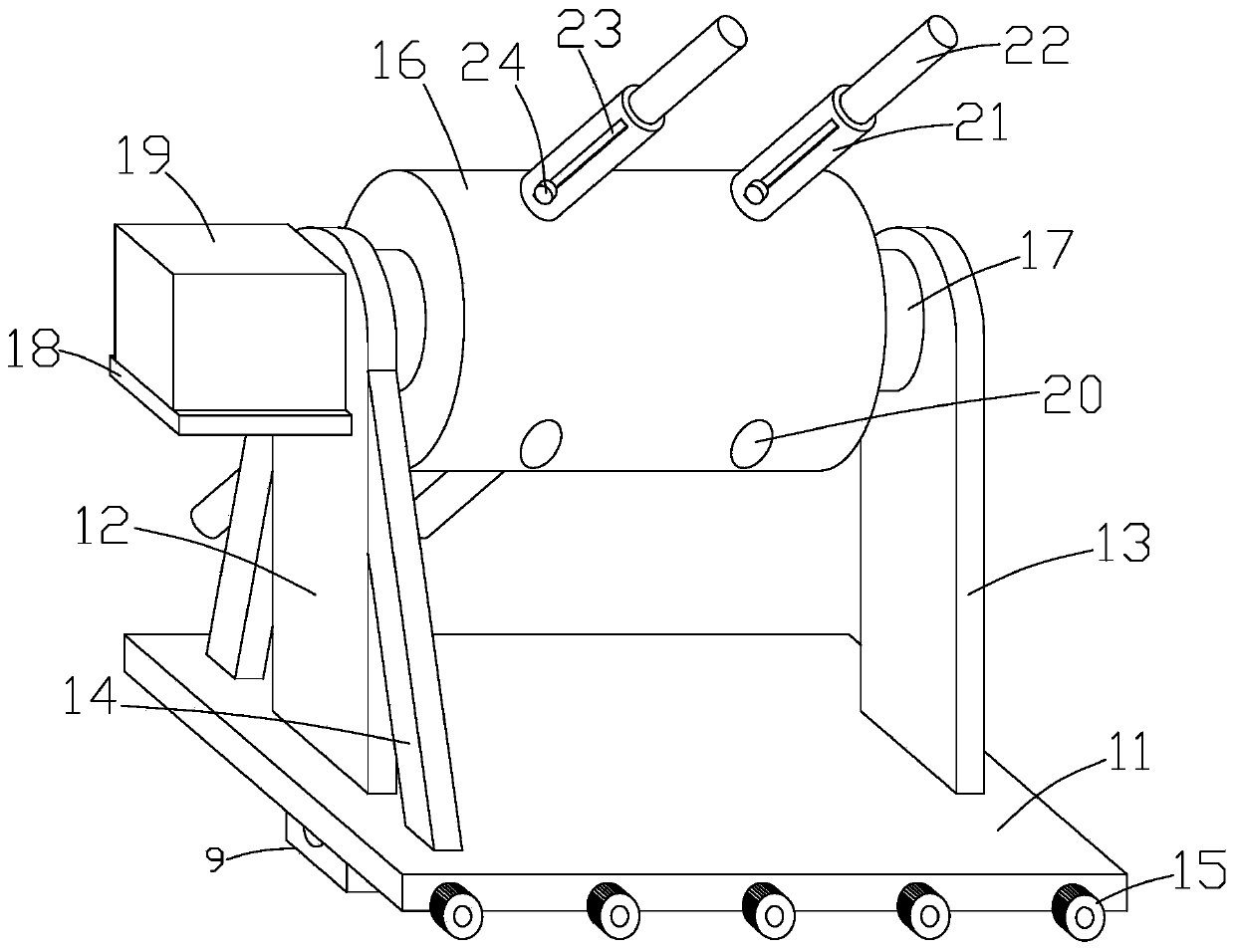

[0105] like Figure 7 As shown, when the distribution of grouting holes is relatively sparse, two drilling mechanisms are used for drilling processing, so that the drilling mechanisms are symmetrically distributed on both sides of the drum, so as to ensure the stability of the rotating mechanism during rotation, and at the same time ensure the stability of the two drilling mechanisms. The force of each drilling mechanism is uniform, so that the depth of the two grouting holes drilled each time is consistent, and the drilling efficiency is improved.

Embodiment 2

[0107] like Figure 8 As shown, when the grouting holes are closely distributed, four drilling mechanisms are used for drilling, so that the drilling mechanisms are evenly distributed around the drum, which not only improves the stability and stability of the entire drilling equipment during work. Reliability, and improve the efficiency of drilling. Compared with manual drilling, it greatly shortens the construction period, improves drilling accuracy, and prevents deviation from affecting the quality of the final grouting pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com