Plate heat exchanger and production method of heat exchange plate groups of plate heat exchanger

A technology of plate heat exchangers and heat exchange plates, which is applied in the direction of heat exchanger types, indirect heat exchangers, chemical instruments and methods, etc., and can solve the problem of poor pressure bearing capacity of heat exchange plate groups, easy separation or damage , low heat transfer efficiency and other issues, to achieve the effect of improving pressure bearing capacity, avoiding detachment, and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is aimed at the plate heat exchanger used for heat exchange between the gas phase and the liquid phase in the prior art. The same as the conventional plate heat exchanger, the plate heat exchanger includes a heat exchange plate group, a sealing device, The inlet, heat exchange passage and outlet of the liquid phase medium, and the inlet, heat exchange passage and outlet of the gas phase medium.

[0038] In the prior art, it is often only concerned with the gas phase and liquid phase that can achieve heat transfer and the corrosion resistance to flue gas, while ignoring the relationship between the reliability of the heat exchange plate assembly and its heat exchange efficiency, specifically On the basis of the structure of the existing heat exchange plate group, if the contact area between the non-metal heat exchange plate and the metal heat exchange plate is too large, it will help to improve the assembly reliability of the heat exchange plate group, but...

Embodiment 2

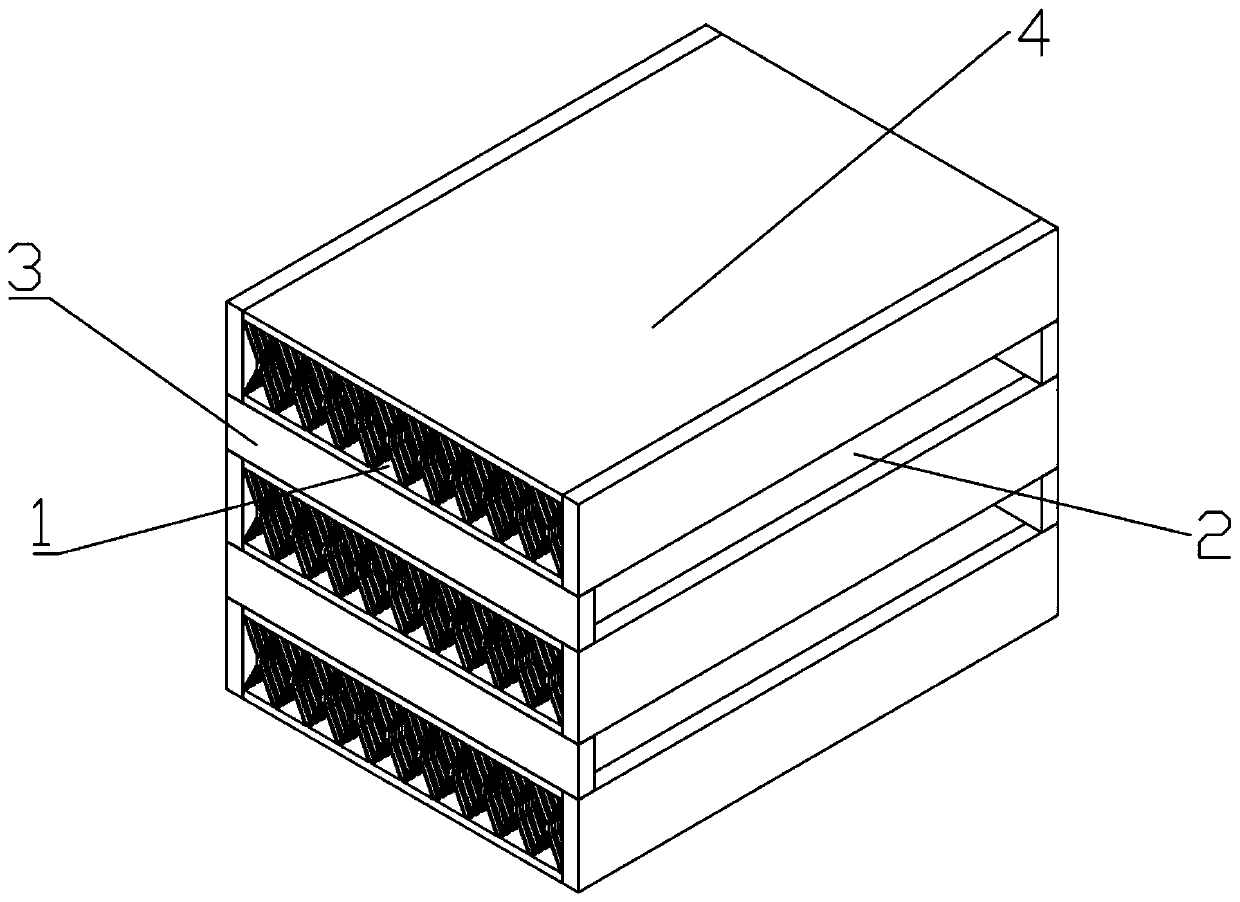

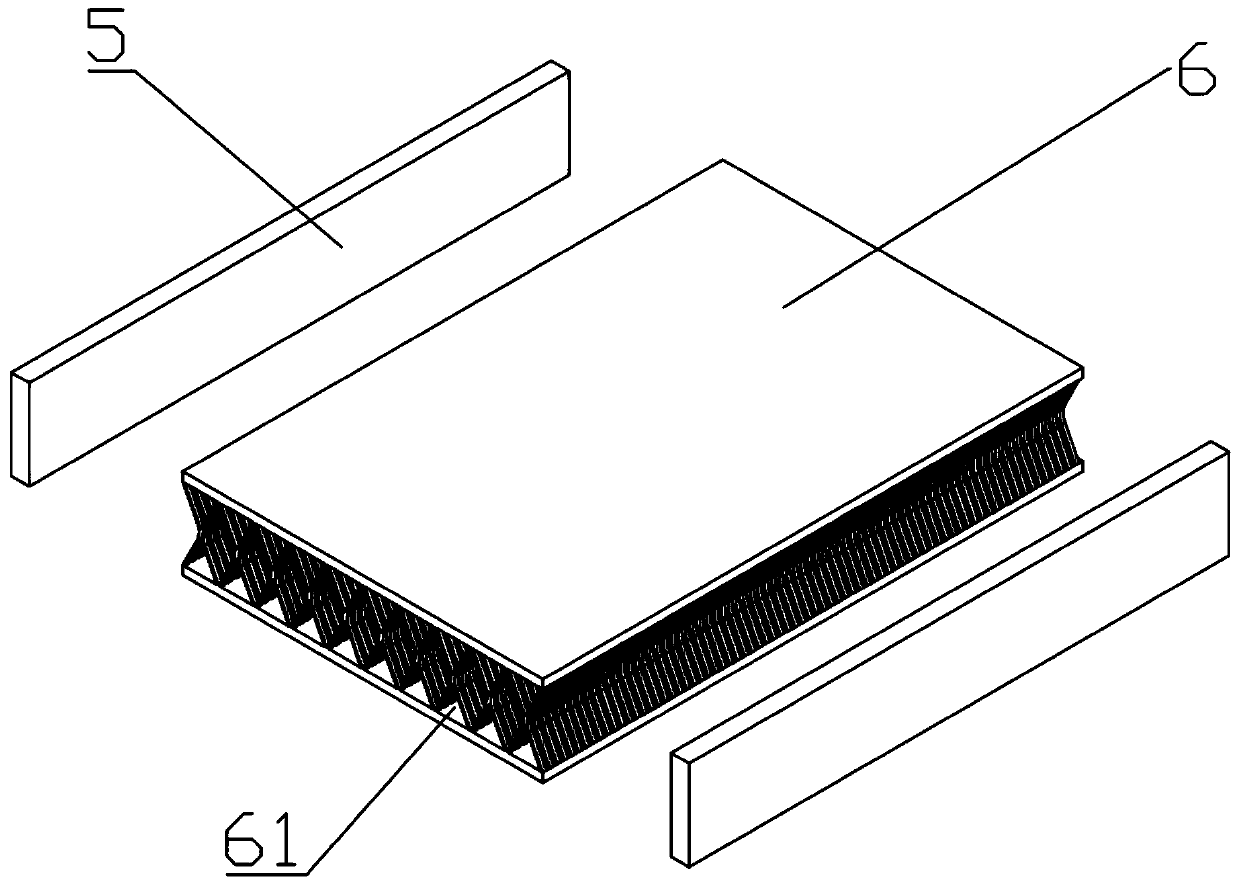

[0045] as attached Figure 1-2 As shown, on the basis of Embodiment 1, this embodiment further introduces the structure of the heat exchange plate group 4:

[0046] The heat exchange plate group 4 also includes a second sealing plate 5, the second sealing plate 5 is connected to the first surface layer 62 and the second surface layer 63 respectively, and the second sealing plate 5, the first surface layer 62 , The liquid phase channel 1 is formed between the second surface layer 63, thereby ensuring the sealing performance of the liquid phase medium channel 1 inside the heat exchange plate group 4 on the one hand, and on the other hand, the first surface layer 62, the second surface layer 62, and the second surface layer can be sealed. The layer 63 and the velvet rib 64 provide a further fixing effect, which is beneficial to improving the assembly reliability of the heat exchange plate group 4 and the plate heat exchanger.

[0047] As another implementation of this embodiment...

Embodiment 3

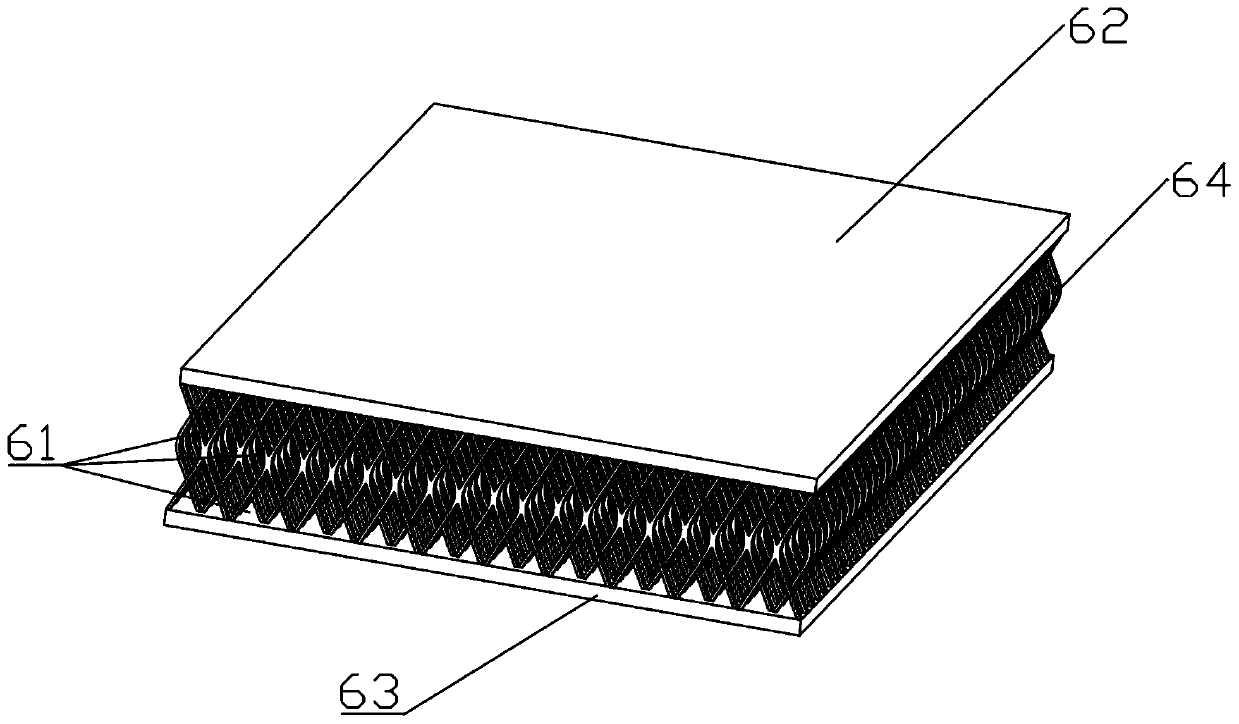

[0049] As described in Embodiment 1, the velvet tendons 64 apply tension to the first surface layer 62 and the second surface layer 63 respectively, that is, the effect of the bearing capacity on the velvet tendons 64 all the time; as attached Figure 4 As shown, in this embodiment, on the basis of Embodiment 1 or Embodiment 2, the setting of the pile 64 is further introduced.

[0050] Described pile tendon 64 comprises the first rib and the second rib that are connected with each other; For the first rib, one end of the first rib is connected with the first surface layer 62, and the other end of the first rib is connected with the second rib. The surface layer 63 is connected; for the second rib, one end of the second rib is connected with the first surface layer 62 or the second surface layer 63, and the other end of the second rib is connected with the first rib.

[0051] Simultaneously, described hollow member 6 also comprises transverse rib, and described transverse rib i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap