Multi-layer chip architecture and connection method

A multi-layer chip and connection method technology, applied in the direction of semiconductor/solid-state device parts, semiconductor devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

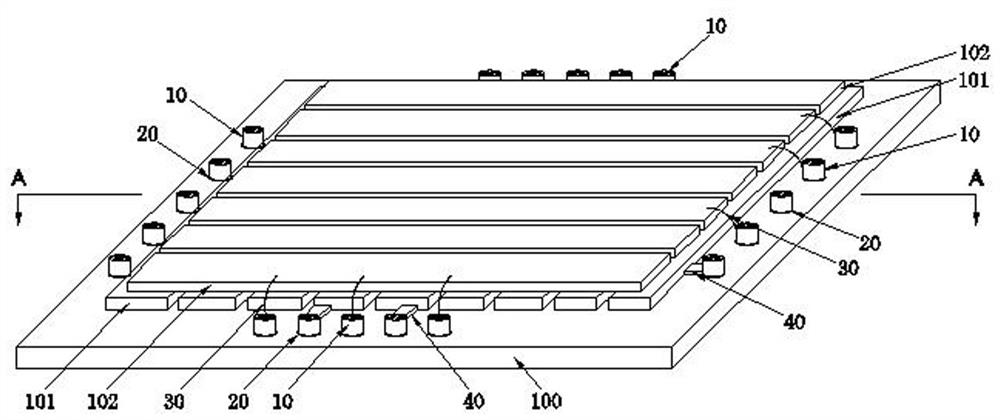

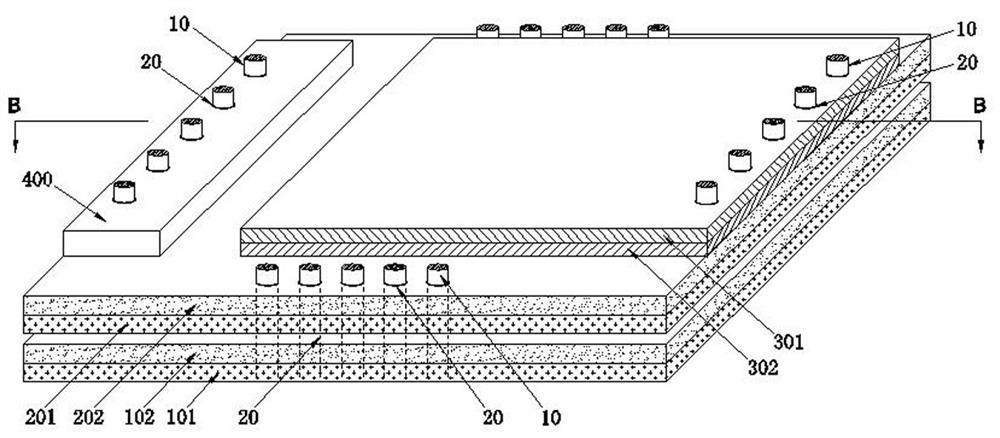

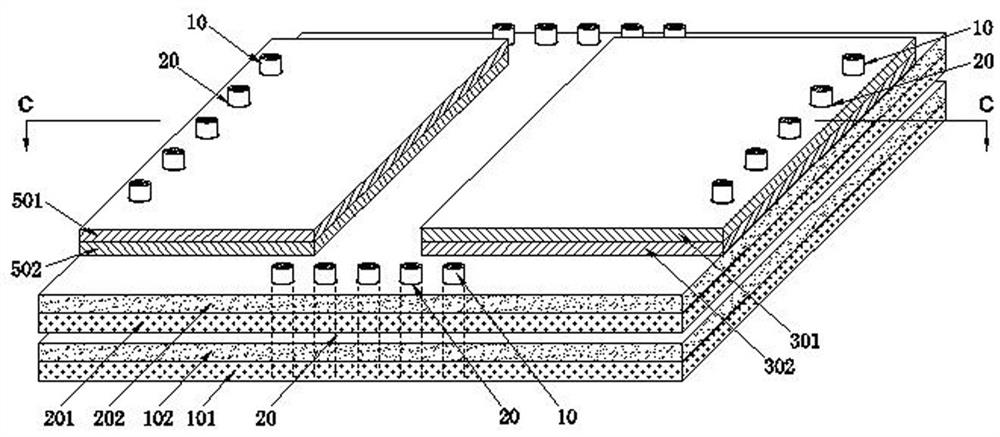

[0041] In a specific embodiment of the present invention, a multi-layer chip in a package includes chips of different geometric dimensions and different functionalized module chips, and a stack of conductive layers and auxiliary layers. In the implementation manner, each layer of stacked chips is arranged at the same position and at least in one direction, through silicon vias for interconnection between chip layers are laid out. The chip implementation of this multi-layer structure can provide optimized circuit design, layout of devices on the chip and wiring for improving electrical connection performance, as well as alignment of through-silicon holes between layers in the manufacturing process and positioning control of metal interconnection processes. The implementation of the present invention is specifically described and explained in detail as follows:

[0042] refer to figure 1 , the method of embodiment 1 includes a schematic diagram of chip architecture and position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com