Method for making moisture-permeable waterproof shoes

A moisture-permeable waterproof and moisture-permeable waterproof membrane technology, applied in the field of shoes, can solve problems such as discomfort, user's foot discomfort, and user's foot burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

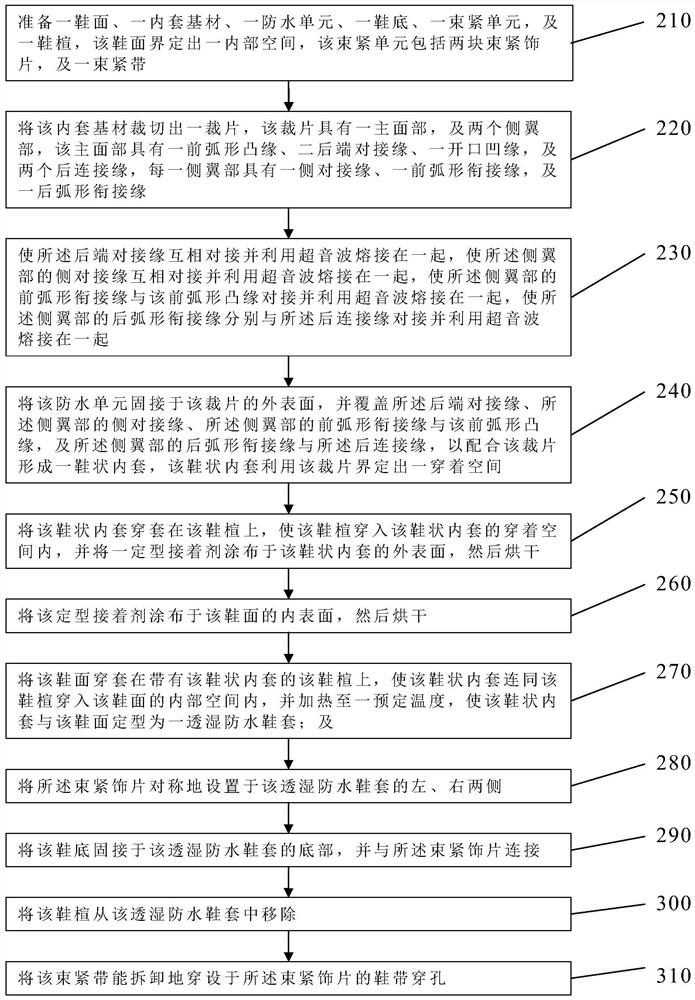

[0049] refer to figure 1 , 2 , is an embodiment of the method for making moisture-permeable waterproof shoes of the present invention, and the method for making moisture-permeable waterproof shoes includes the following steps:

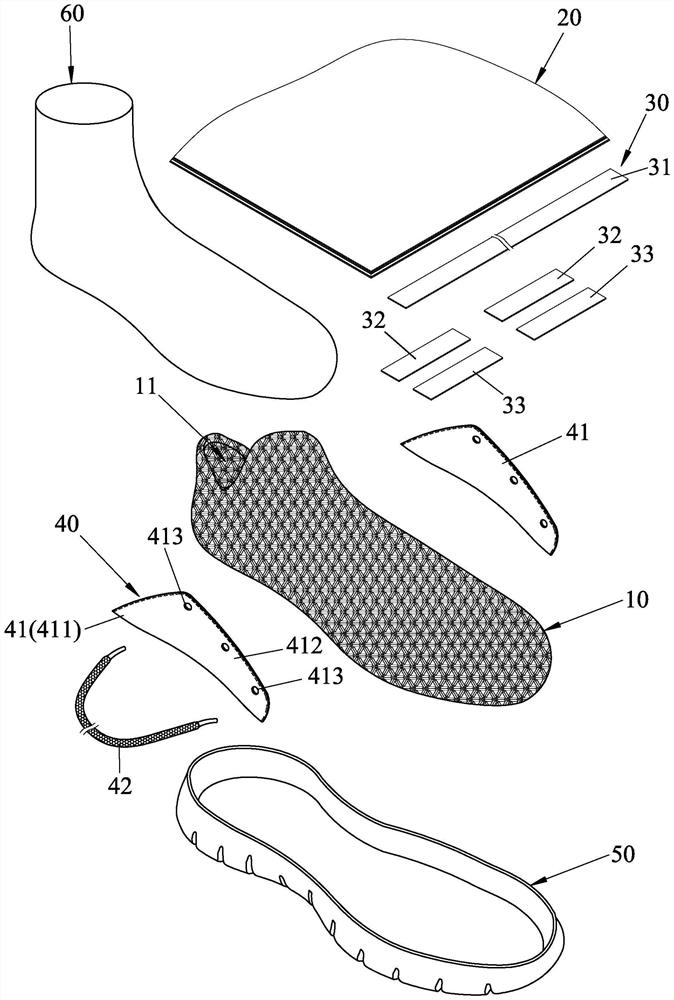

[0050] Step 210: if figure 1 , 2 , 3, prepare a shoe upper 10, an inner cover substrate 20, a waterproof unit 30, a tightening unit 40, a sole 50, and a shoe last 60.

[0051] The vamp 10 defines an inner space 11 with an open top. In this embodiment, the vamp 10 is in the shape of a sock, but it is not limited thereto.

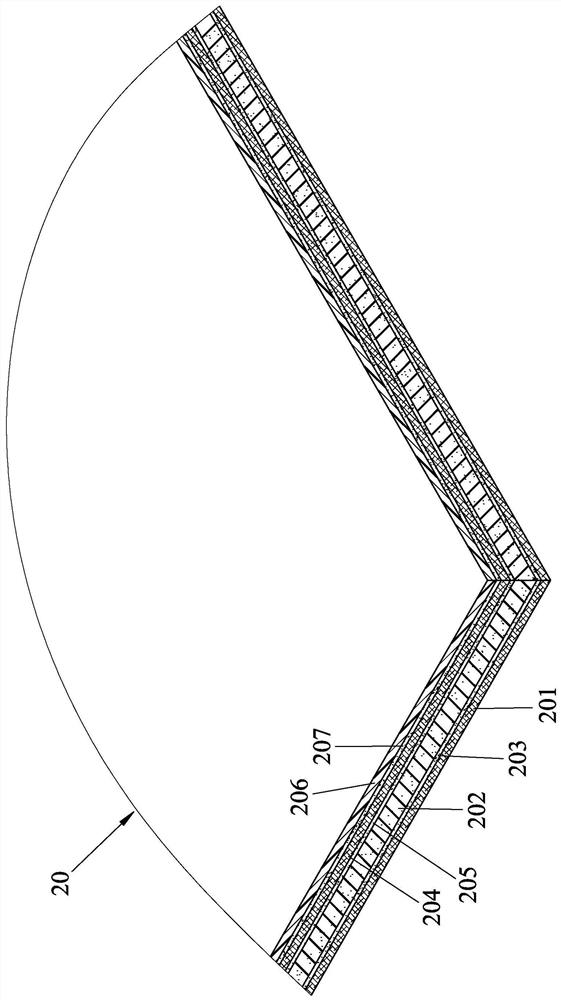

[0052] The inner cover substrate 20 includes an inner lining 201, a foam sheet 202 outside the inner lining 201, an adhesive 203 bonded between the inner lining 201 and the foam sheet 202, The surface cloth 204 on the outside of the cotton sheet 202, an adhesive 205 bonded between the foam sheet 202 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com