Machining method of spatial angle small hole of aviation component

A technology of space angle and processing method, which is applied in the field of aero-engines, can solve problems such as long processing time, low processing quality, and unstable processing efficiency, so as to improve the stability of processing quality, improve processing efficiency, and avoid calculation process and processing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0054] Part aperture requirement is Φ0.6 0 +0.05 And the five-axis high-speed EDM machine tool has a discharge gap of 0.03 to 0.05, so the Φ0.55 electrode is used for processing;

[0055] 1. Clamp the parts on the working turntable of the five-axis high-speed EDM machine tool, use a dial gauge to check the runout value of the reference circle of the aviation parts, and make fine adjustments to ensure that the runout value is not greater than the roundness of the reference circle +0.02 Align and clamp the parts so that the center of the parts coincides with the center of the work turntable;

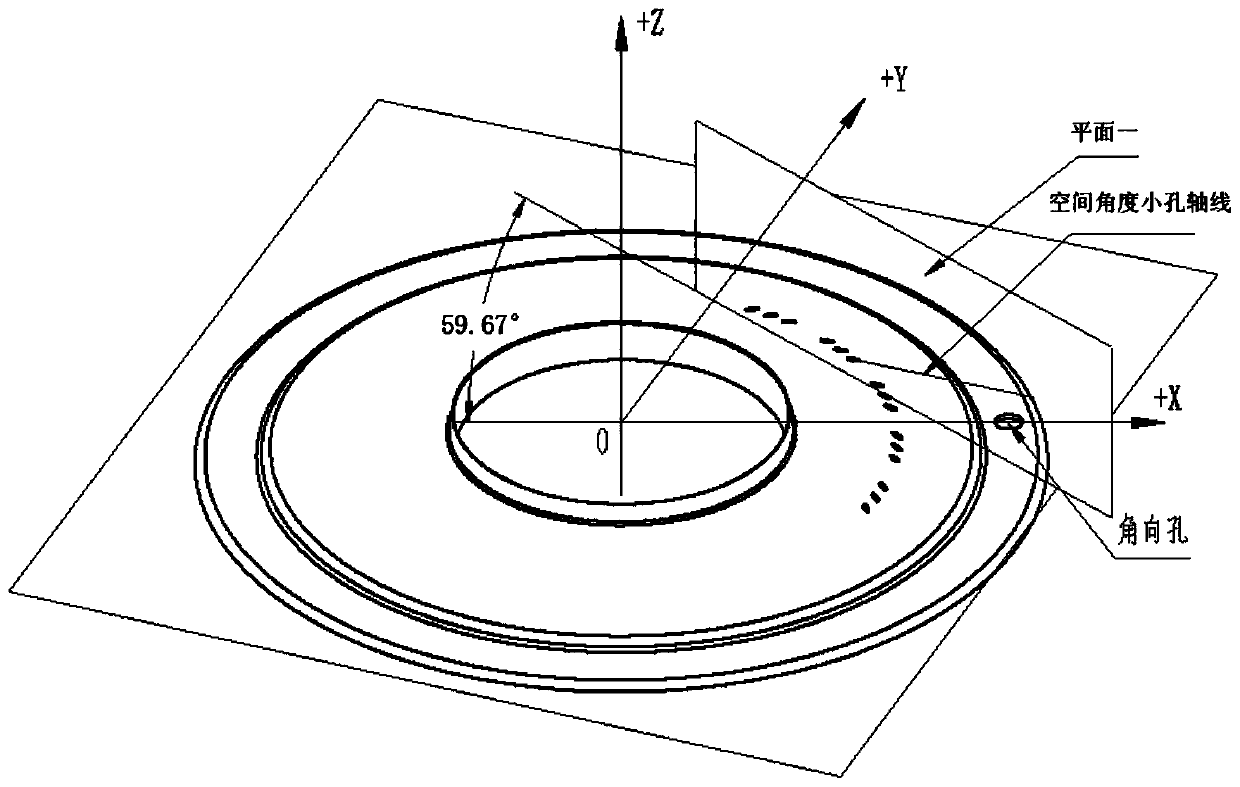

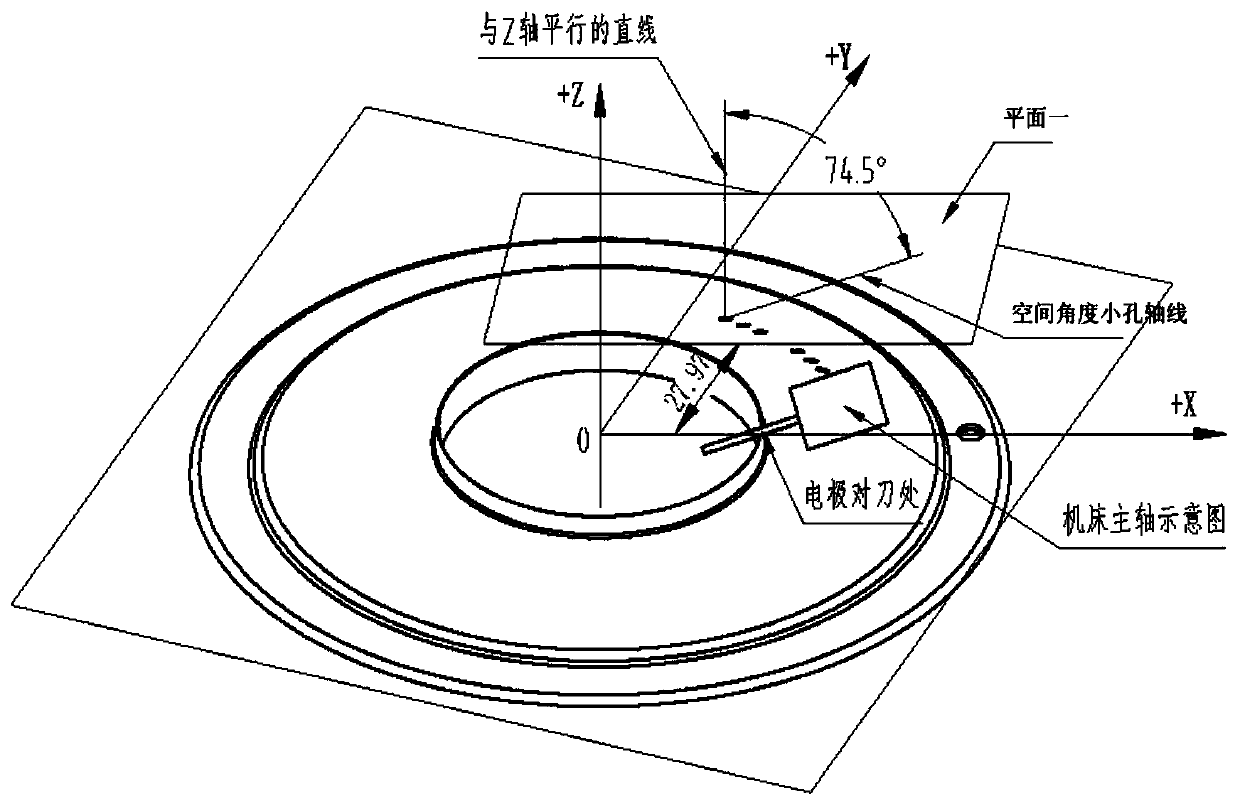

[0056] 2. Establish a working Cartesian coordinate system, such as figure 1 As shown, the intersection point of the central axis of the part (the center of the turntable) and the reference plane is set as the coordinate origin; the direction from the work turntable to the electrode spindle through the origin is the positive direction of the Z axis; the X coordinate is horizontal and perp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com