Joining structure and joining method

一种接合方法、构造体的技术,应用在化学仪器和方法、焊接/焊接/切割物品、导体等方向,能够解决龟裂、工件破坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

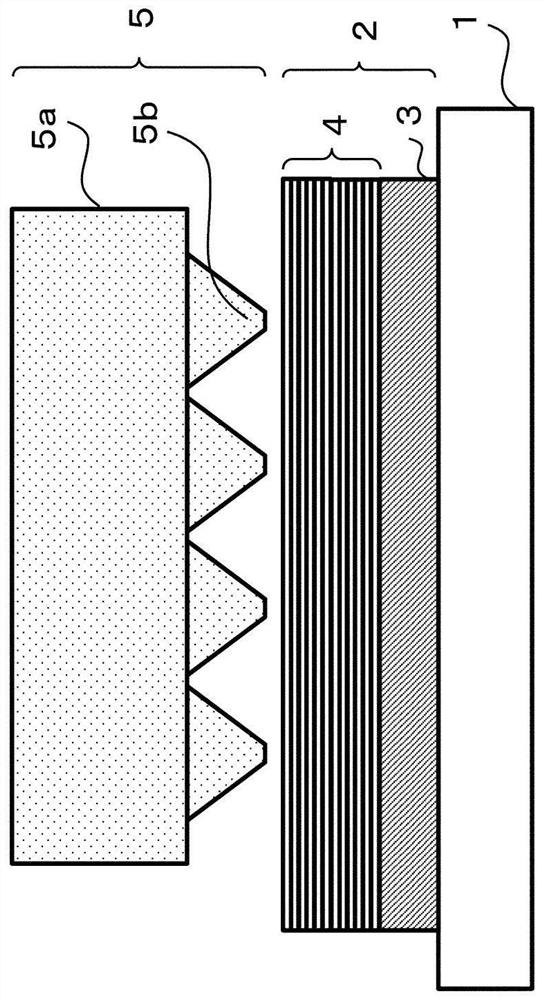

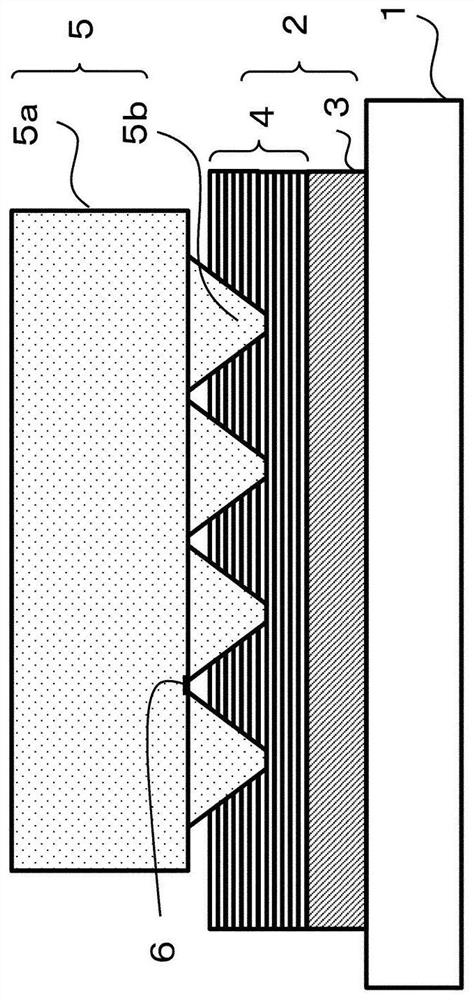

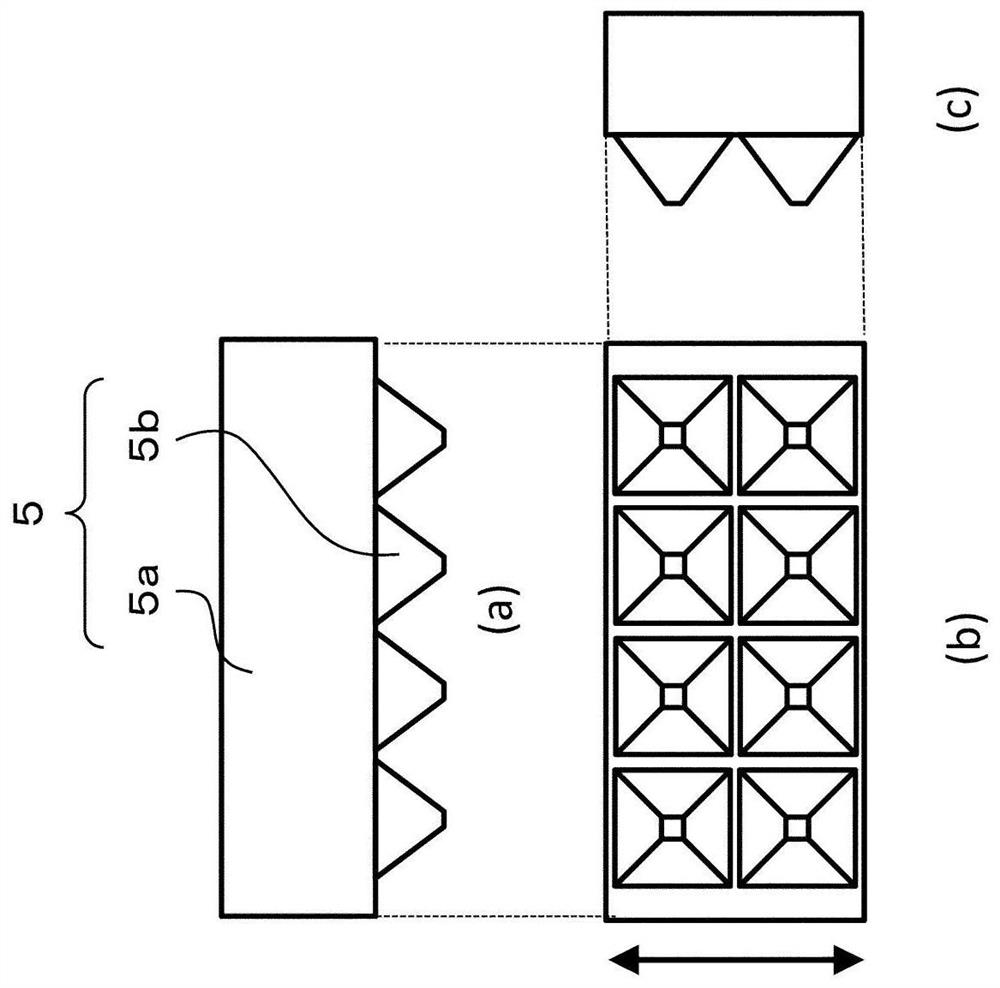

[0038] The joint structure according to the first embodiment is a joint structure in which a plurality of metals are laminated and joined. Between the flat portion, the front ends of the plurality of convex portions are made of curved surfaces. An example of this joint construct is set to Figure 4 The illustrated junction structure 7 is a laminated current collector plate 3 and electrode foil 4 . That is, as a plurality of metals, the electrode foil 4 and the collector plate 3 are exemplified. The electrode foil 4 is a laminate of a plurality of metal foils. The metal foil is copper foil. The collector plate 3 is a copper plate. In this case, for example, the collector plate 3 constitutes a copper wire in the lithium secondary battery, and the electrode foil 4 constitutes a negative electrode. However, the present disclosure is not limited to the current collector plate 3 or the electrode foil 4 , as long as it is a metal that can be ultrasonically bonded. The current c...

no. 2 Embodiment approach

[0060] Image 6 It is a schematic sectional view which shows the preparation process of the ultrasonic bonding in 2nd Embodiment. In addition, matters not described are the same as those of the first embodiment. The difference from the first embodiment is that the section parallel to the main surface of the anvil 5 ( Image 6 The cross-sectional area of the protrusion bottom surface 10 at the cross-section in the depth direction) is not uniform.

[0061] In the bonding step, the electrode foil 4 straddles between adjacent protrusions 5 b and spreads to the peripheral portion of the anvil 5 . The electrode foil 4 spreading from the center portion of the anvil 5 to the peripheral portion flows between the protrusions 5 b located at the peripheral portion of the anvil 5 . Furthermore, the electrode foil 4 located outside the anvil 5 also flows into between the protrusions 5 b located in the peripheral portion of the anvil 5 . Therefore, more electrode foil 4 flows between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com