A tire tread extruded product turning device

A technology for extruding products and turning devices, which is applied to tires, household appliances, and other household appliances. It can solve the problems of reduced production speed, high cost, and large range of screw extruders, and achieves increased production speed, increased output, and The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]The present invention will be further described in detail below with reference to the accompanying drawings.

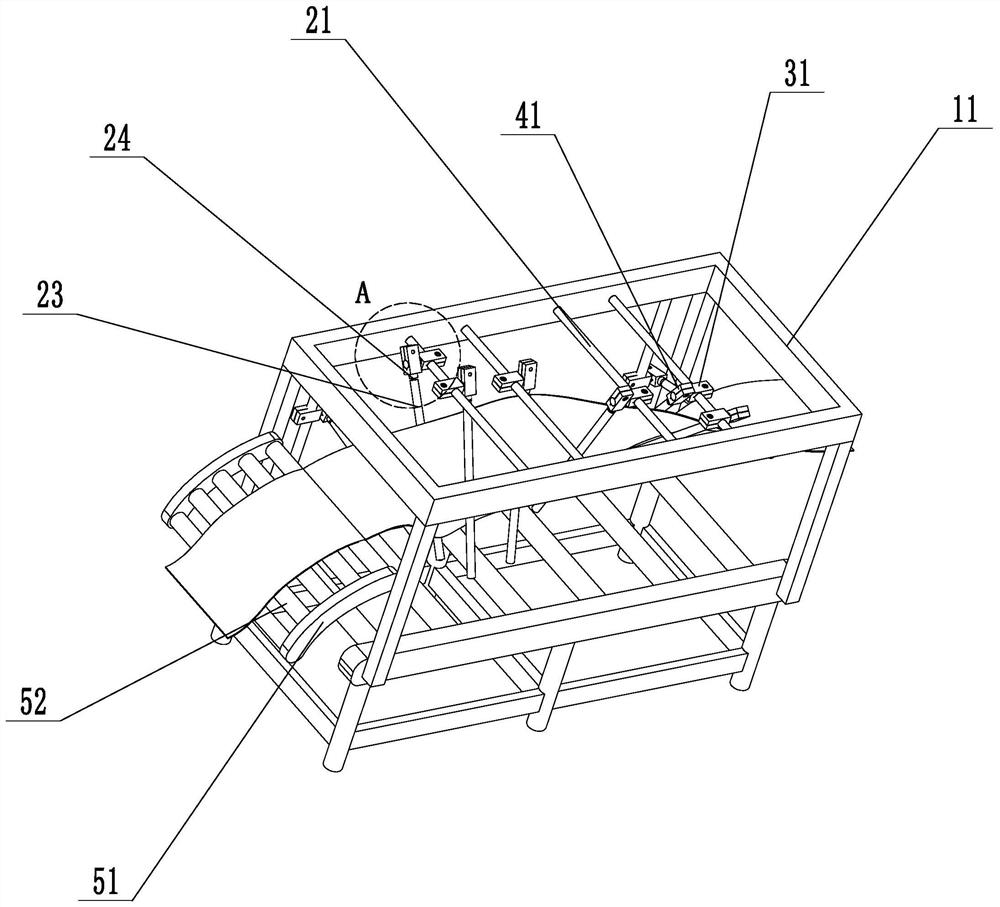

[0044]Referfigure 1 withfigure 2 For a tire tire pole pressed article flip device disclosed in the present invention, a flip frame 11 and a flipped structure and a transition portion disposed on the flip frame 11.

[0045]The flip frame 11 is made of profile, including a rectangular frame and an leg that is fixed to four corners of the rectangle frame, and the flip frame 11 is directly welded or bolted to the original transporter.

[0046]The flip structure is composed of a crossbar 21, a first restricted block, a second restricted block, and a voltage rod 24, and the like. The crossbar 21 is made of a circular tube or a rod, and the cut is fixed to the rectangular frame of the flip frame 11, and its axis is perpendicular to the direction of movement of the tread.

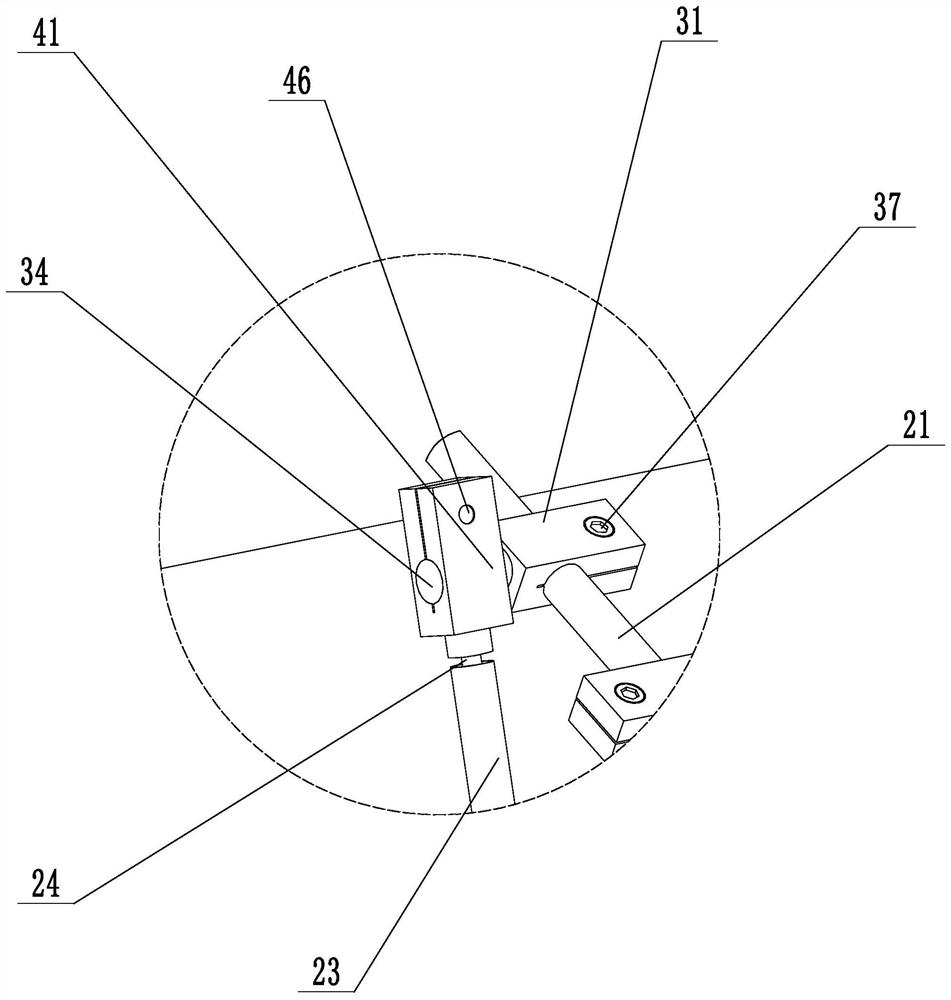

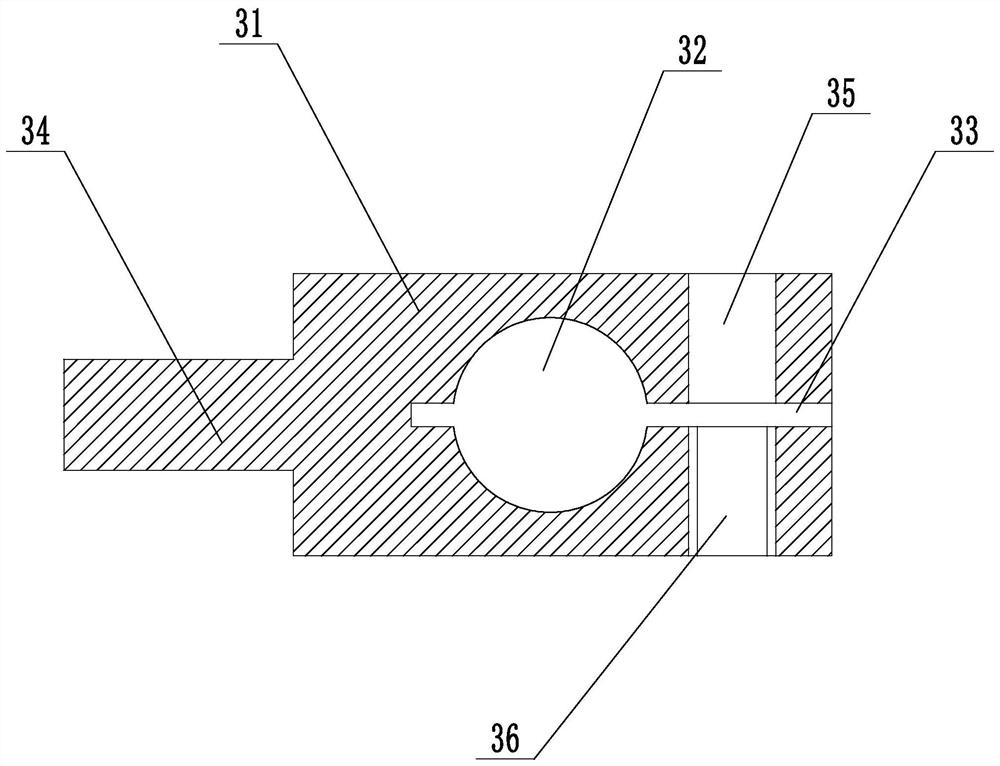

[0047]Referfigure 2 withimage 3 The body of the first position block is the first block 31, and there is a first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com