Battery management cooling system for electric automobile

An electric vehicle and battery management technology, applied in the field of cooling systems, can solve the problems of high energy consumption, unfavorable small-volume heat dissipation mode, and single heat dissipation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

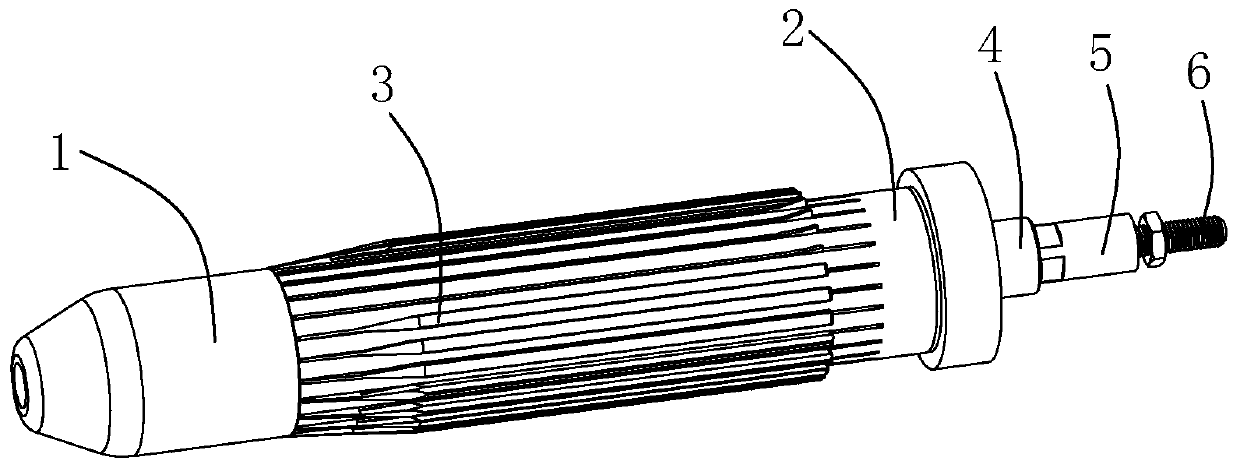

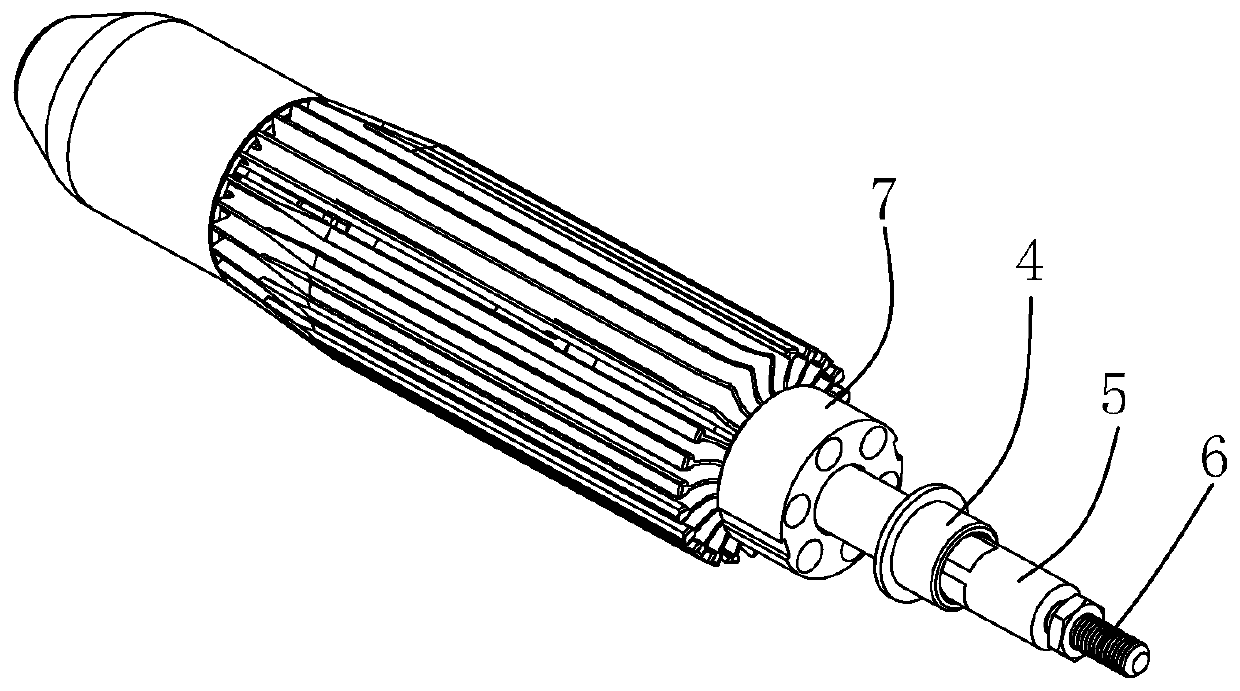

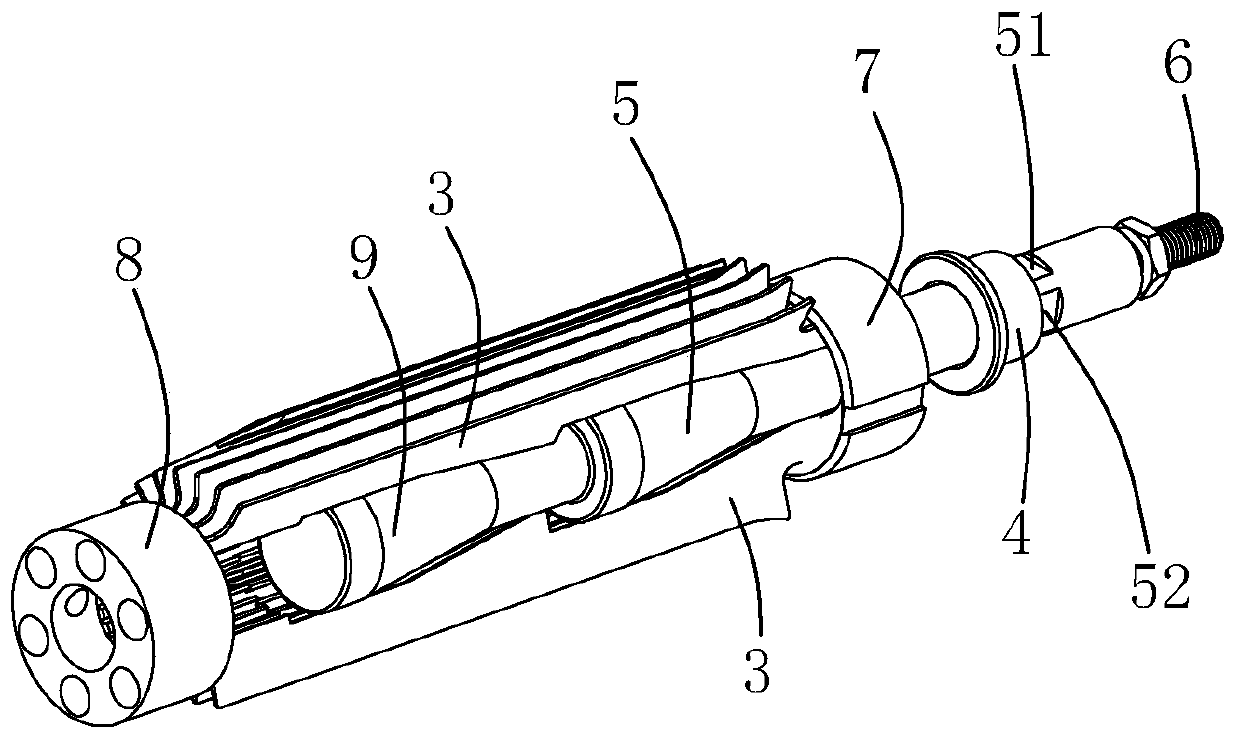

[0031] Embodiment: A cooling system for battery management of an electric vehicle, its main structure includes: fairing 1, air groove adjustment cylinder 2, slot 21, heat sink 3, barge collar 4, cold storage source cylinder 5, liquid inlet 51. Drain port 52, threaded groove 53, spool 6, screw member 61, fin beam ring 7 at the end, beam ring 8 at the top, cold source return cylinder 9, drain hole 91, sealing cover 10, Nut ring 11, screw rod 12, stepper motor 13, base platform 14, screw barrel 141, air intake grille 15, described tail end heat sink bundle ring 7, top heat sink bundle ring 8 are all provided with insertion slots ; A heat sink 3 is fixed between the tail-end heat sink beam ring 7 and the top heat sink beam ring 8 through an insert slot; a plurality of ring-shaped heat sinks 3 are arranged to form a heat sink;

[0032] The side wall of the air groove regulating cylinder 2 is equidistantly opened with slots 21, and each of the slots 21 is inserted with a cooling fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com