Multi-layer material vehicle capable of automatically taking materials

A technology of automatic reclaiming and feeding of materials, which is applied in the direction of motor vehicles, multi-axle trolleys, trolleys, etc., can solve the problems of poor safety performance, high cost, affecting production efficiency, etc., to avoid potential safety hazards, reduce transportation times, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

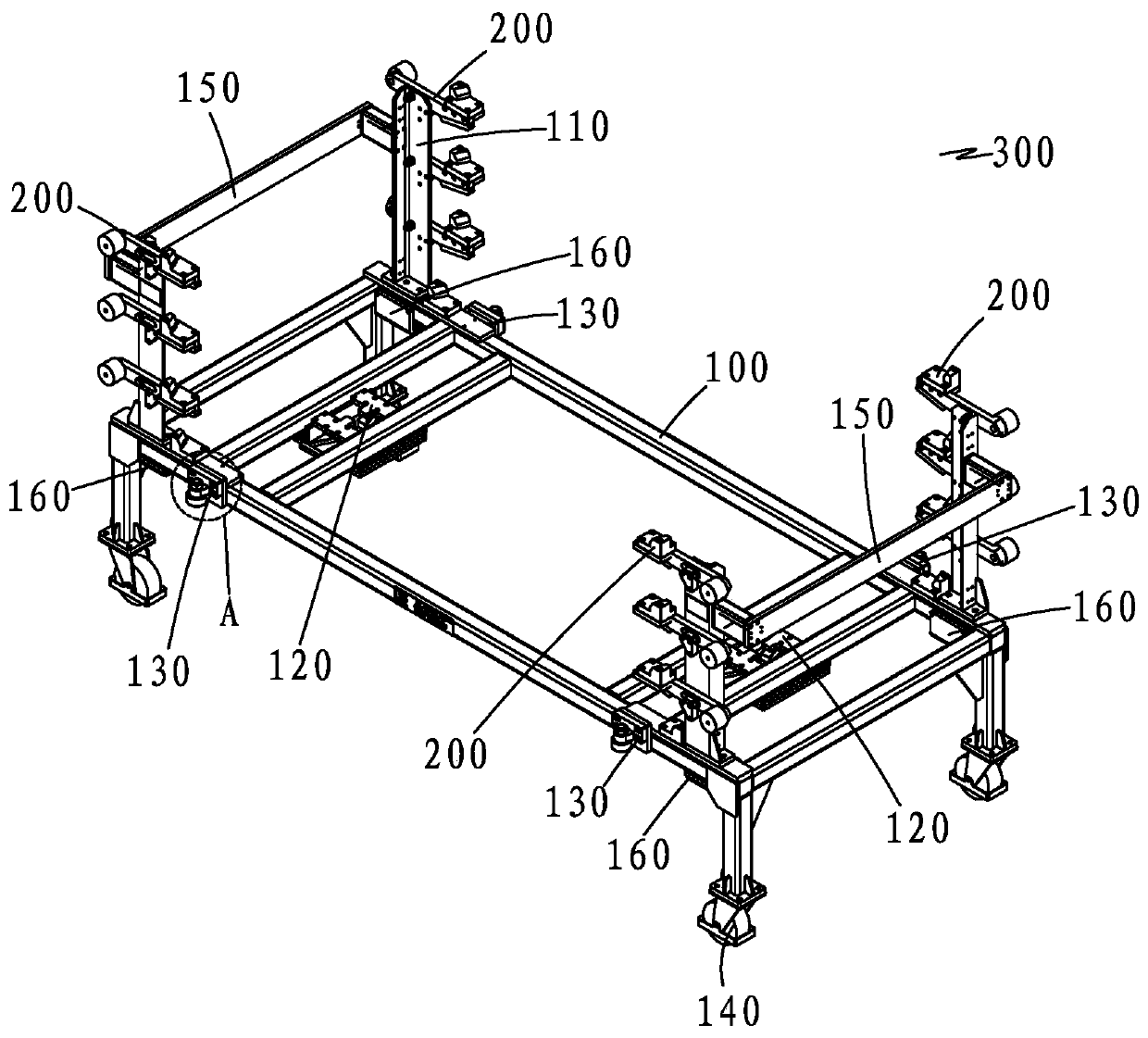

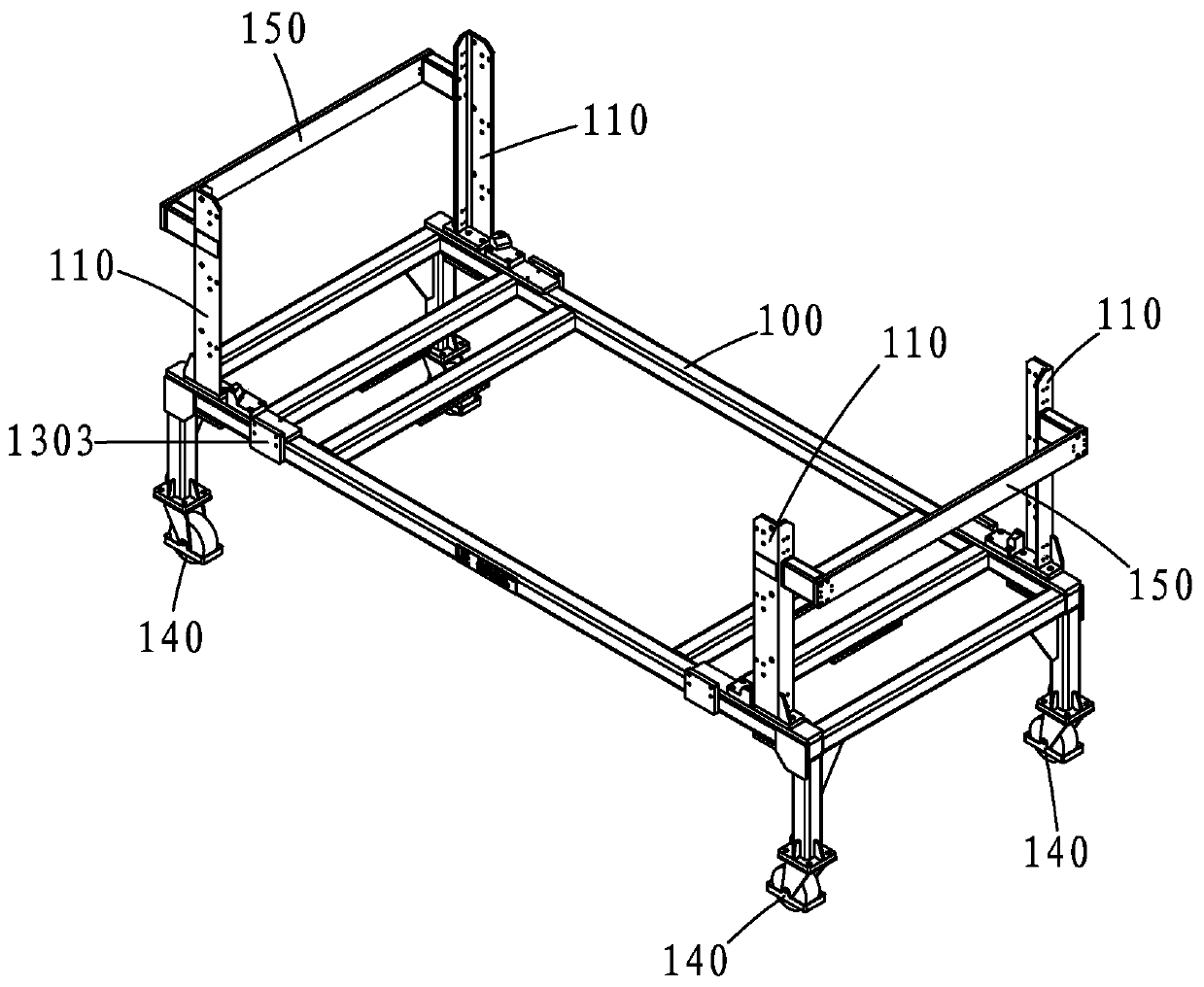

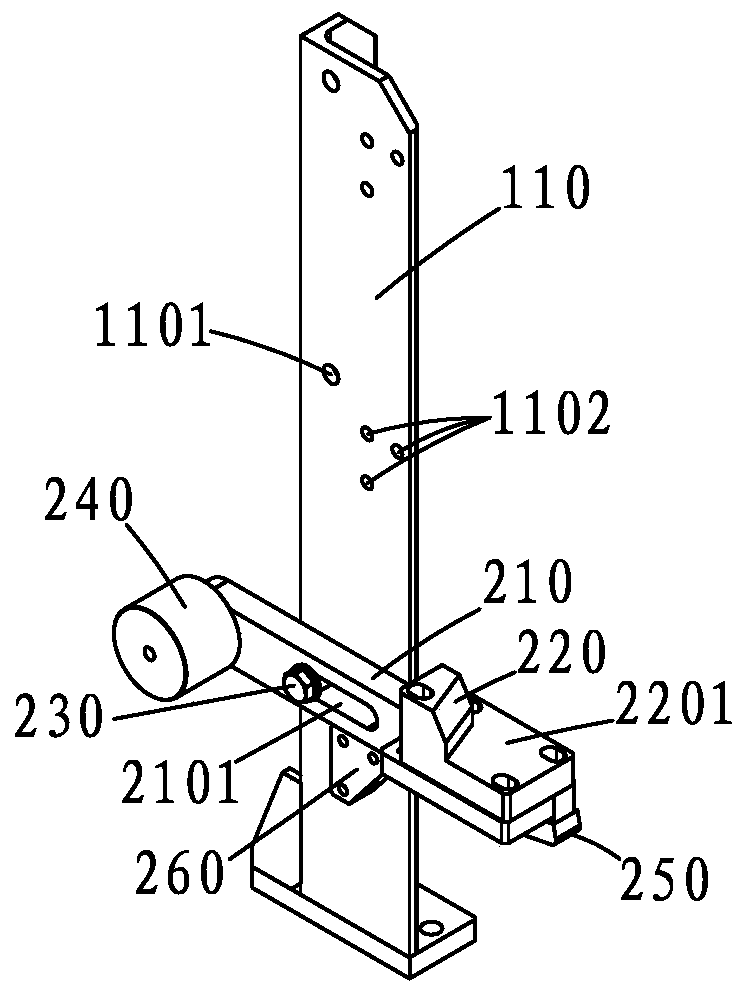

[0046] A positioning mechanism is installed at the place where the material cart is placed in the processing area, and the positioning mechanism is only installed on one side, and four guide wheel devices 130 are symmetrically installed on the material vehicle 300, which facilitates the positioning of the AGV vehicle without turning around Distinguish the direction, and locate on any side to improve work efficiency. The positioning mechanism includes a V-shaped block 400 and a clamping cylinder 500. The V-shaped block 400 cooperates with the guide wheel device 130 to facilitate positioning. After it is in place, the clamping cylinder 500 It is locked with the locking fixed block 160 to prevent the moving of the feed truck and ensure smoother and more accurate hoisting.

[0047] In the material storage warehouse, the material is manually loaded, and the shell is placed on the flip support mechanism 200 of each layer. After being placed, the staff sends instructions to the AGV ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com