Baffling type anaerobic reactor

A baffled anaerobic reactor technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Costs and other issues, to achieve the effect of improving digestibility and gas production rate, improving digestibility, and solving indigestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

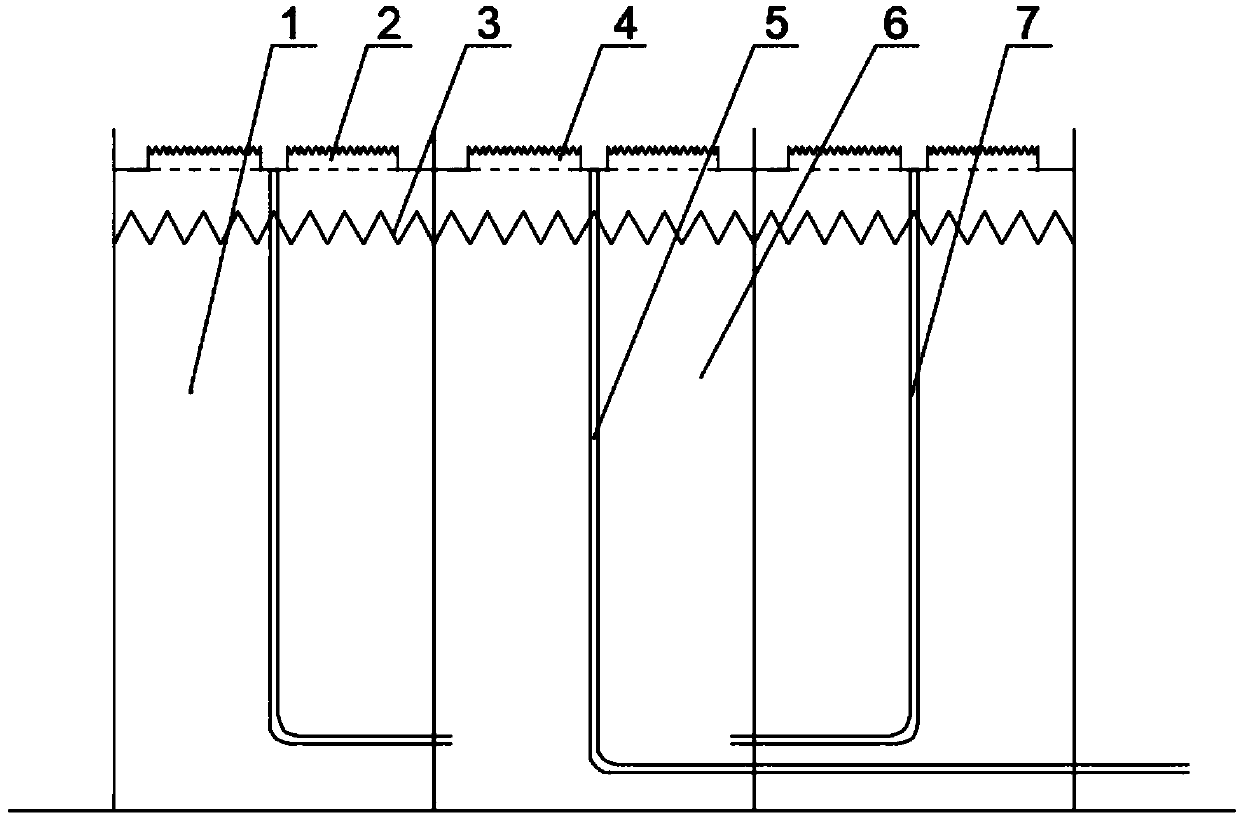

[0011] A baffled anaerobic reactor, comprising a primary fermentation chamber 1 and a secondary fermentation chamber 6, the tops of the primary fermentation chamber and the secondary fermentation chamber are provided with weirs, and the interior of the primary fermentation chamber and the secondary fermentation chamber are also Three separators 3 are provided, the primary fermentation chamber is arranged on the left and right sides of the secondary fermentation chamber, and the top of the primary fermentation chamber is provided with a baffle pipe 7 connecting the outlet weir 2 of the primary fermentation chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com